Page 18 - MMI-Oct2022- upload

P. 18

COVER STORY

WORKING IN TANDEM

The ‘additive versus subtractive’ war is passé. Listed below are 10 ways that

show how machining and metal additive manufacturing are interconnected

and enhance each other’s possibilities.

Source: Modern Machine Shop

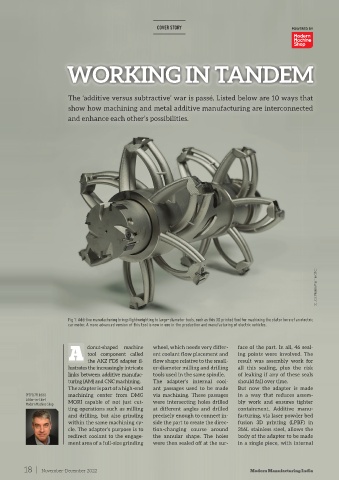

Fig 1: Additive manufacturing brings lightweighting to large-diameter tools, such as this 3D printed tool for machining the stator bore of an electric

car motor. A more advanced version of this tool is now in use in the production and manufacturing of electric vehicles.

donut-shaped machine wheel, which needs very differ- face of the part. In all, 46 seal-

A tool component called ent coolant flow placement and ing points were involved. The

result was assembly work for

flow shape relative to the small-

the AKZ FDS adapter il-

lustrates the increasingly intricate er-diameter milling and drilling all this sealing, plus the risk

links between additive manufac- tools used in the same spindle. of leaking if any of these seals

turing (AM) and CNC machining. The adapter’s internal cool- should fail over time.

The adapter is part of a high-end ant passages used to be made But now the adapter is made

PETER ZELINSKI machining center from DMG via machining. These passages in a way that reduces assem-

Editor-in-Chief MORI capable of not just cut- were intersecting holes drilled bly work and ensures tighter

Modern Machine Shop

ting operations such as milling at different angles and drilled containment. Additive manu-

and drilling, but also grinding precisely enough to connect in- facturing, via laser powder bed

within the same machining cy- side the part to create the direc- fusion 3D printing (LPBF) in

cle. The adapter’s purpose is to tion-changing course around 316L stainless steel, allows the

redirect coolant to the engage- the annular shape. The holes body of the adapter to be made

ment area of a full-size grinding were then sealed off at the sur- in a single piece, with internal

18 | No v emb er-D ecemb er 2022 M od ern M an ufacturin g I ndia

18 | November-December 2022

Modern Manufacturing India