Page 25 - MMI- Aug2022

P. 25

Source: Modern Machine Shop

As parts

come off

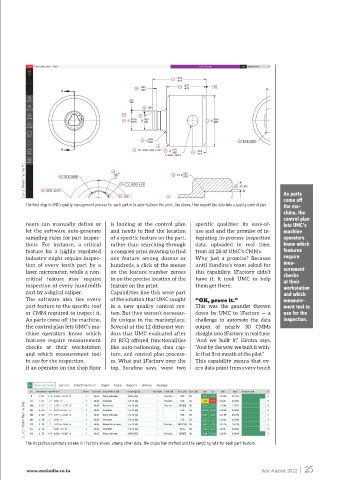

The first step in UMC’s quality management process for each part is to auto-balloon the print, like above, then export the data into a quality control plan. the ma-

chine, the

control plan

neers can manually define or is looking at the control plan specific qualities: its ease-of- lets UMC’s

let the software auto-generate and needs to find the location use and and the promise of in- machine

sampling rules for part inspec- of a specific feature on the part, tegrating in-process inspection operators

tions. For instance, a critical rather than searching through data, uploaded in real time, know which

feature for a highly regulated a complex print drawing to find from all 28 of UMC’s CMMs. features

industry might require inspec- one feature among dozens or Why just a promise? Because require

tion of every tenth part by a hundreds, a click of the mouse until Sundine’s team asked for mea-

surement

laser micrometer, while a non- on the feature number zeroes this capability, 1Factory didn’t checks

critical feature may require in on the precise location of the have it. It took UMC to help at their

inspection of every hundredth feature on the print. them get there. workstation

part by a digital caliper. Capabilities like this were part and which

The software also ties every of the solution that UMC sought “OK, prove it.” measure-

part feature to the specific tool in a new quality control sys- This was the gauntlet thrown ment tool to

or CMM required to inspect it. tem. But they weren’t necessar- down by UMC to 1Factory — a use for the

As parts come off the machine, ily unique in the marketplace. challenge to automate the data inspection.

the control plan lets UMC’s ma- Several of the 12 different ven- output of nearly 30 CMMs

chine operators know which dors that UMC evaluated after straight into 1Factory in real time.

features require measurement its RFQ offered functionalities “And we built it,” Girotra says.

checks at their workstation like auto-ballooning, data cap- “And by the way, we built it with-

and which measurement tool ture, and control plan process- in that first month of the pilot.”

to use for the inspection. es. What put 1Factory over the This capability means that ev-

If an operator on the shop floor top, Sundine says, were two ery data point from every touch

Source: Modern Machine Shop

The inspection summary screen in 1Factory shows, among other data, the inspection method and the sampling rate for each part feature.

July-August 2022 | 25

www.mmindia.co.in