Page 28 - MMI - MayJune2022 small-single

P. 28

VISIT US:

IMTEX 2022

HALL # 4 BOOTH # C101

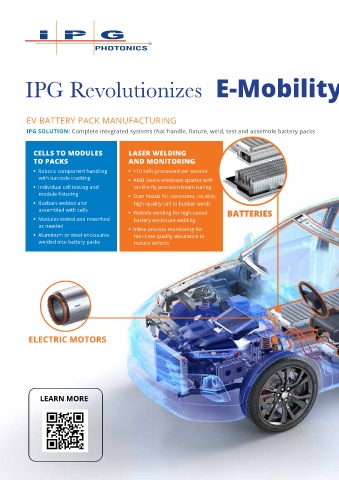

IPG Revolutionizes E-Mobility Applications VENUE – BIEC, BENGALURU

DATES – JUNE 16 - 21, 2022

EV BATTERY PACK MANUFACTURING EV Battery

IPG SOLUTION: Complete integrated systems that handle, fixture, weld, test and assemble battery packs Welding Solutions

CELLS TO MODULES LASER WELDING

TO PACKS AND MONITORING ADJUSTABLE MODE

• Robotic component handling • >10 cells processed per second

with barcode tracking • AMB lasers eliminate spatter with BEAM (AMB) LASERS

• Individual cell testing and on-the-fly precision beam tuning • Spatter reduction on EV batteries for improved

module fixturing • Scan heads for consistent, reliable, reliability and safety

• Busbars welded and high-quality cell to busbar welds • Superior welding quality

assembled with cells

• Wobble welding for high-speed BATTERIES of challenging dissimilar

• Modules tested and reworked battery enclosure welding materials

as needed

• Inline process monitoring for • Faster, more uniform

• Aluminum or steel enclosures real-time quality assurance to high-speed welding

welded into battery packs reduce defects

HIGH POWER

SCAN HEADS

• Consistent, precise,

high-speed welding of

cells to bus bars

• High strength welds with

no seal damage

• Consistent penetration depth

ELECTRIC MOTORS

INLINE WELD MONITORING

• In-weld real-time monitoring and control

for optimal battery welds

LEARN MORE • Eliminates the need for destructive testing

• Reduces scrap and increases

overall throughput

• Identifies problems before

processing begins