Pushing Boundaries

Infamous for being reluctant in adopting disruptive technologies, the Indian market is surprisingly witnessing a whopping rise in robot installations. Domestic startup ASIMOV Robotics Pvt Ltd is playing a crucial role in digitally transforming many an enterprise in several sectors with their innovative offerings.

ASIMOV Robotics had quite an interesting start to it. The company came into being as a continuation of another initiative in the robotics space by the same team which was under the contract of a US company to design, develop and export robot platforms to government and private agencies in the US, Central America, Europe, Canada, and China.

ASIMOV Robotics had quite an interesting start to it. The company came into being as a continuation of another initiative in the robotics space by the same team which was under the contract of a US company to design, develop and export robot platforms to government and private agencies in the US, Central America, Europe, Canada, and China.

“During that period, we were fortunate to connect with the world’s top universities to understand that the research activities in the robotic space were heading towards the development of service robotics,” shares Jayakrishnan T, Founder & CEO, ASIMOV Robotics Pvt Ltd, who possesses over 20 years of experience in Robotics, having previously worked on projects for the US Army, Lockheed Martin, Canadian Space Agency, and Fukushima Nuclear Reactor Japan.

Other team members include COO, Saju G Namboothiri who has over 20 years of experience in Automotive Embedded Systems and Automation; Lead Engineer, Rajesh Subramanian who is experienced in Manipulation, Navigation, NLP, and Computer Vision and has worked with Humanoids, Delivery Bots, and Barista Robots; and Dr Ritesh Malik, MBBS, Serial Entrepreneur/Investor, Ex-Y-combinator who is ASIMOV’s Seed Investor and Advisor.

The journey ahead

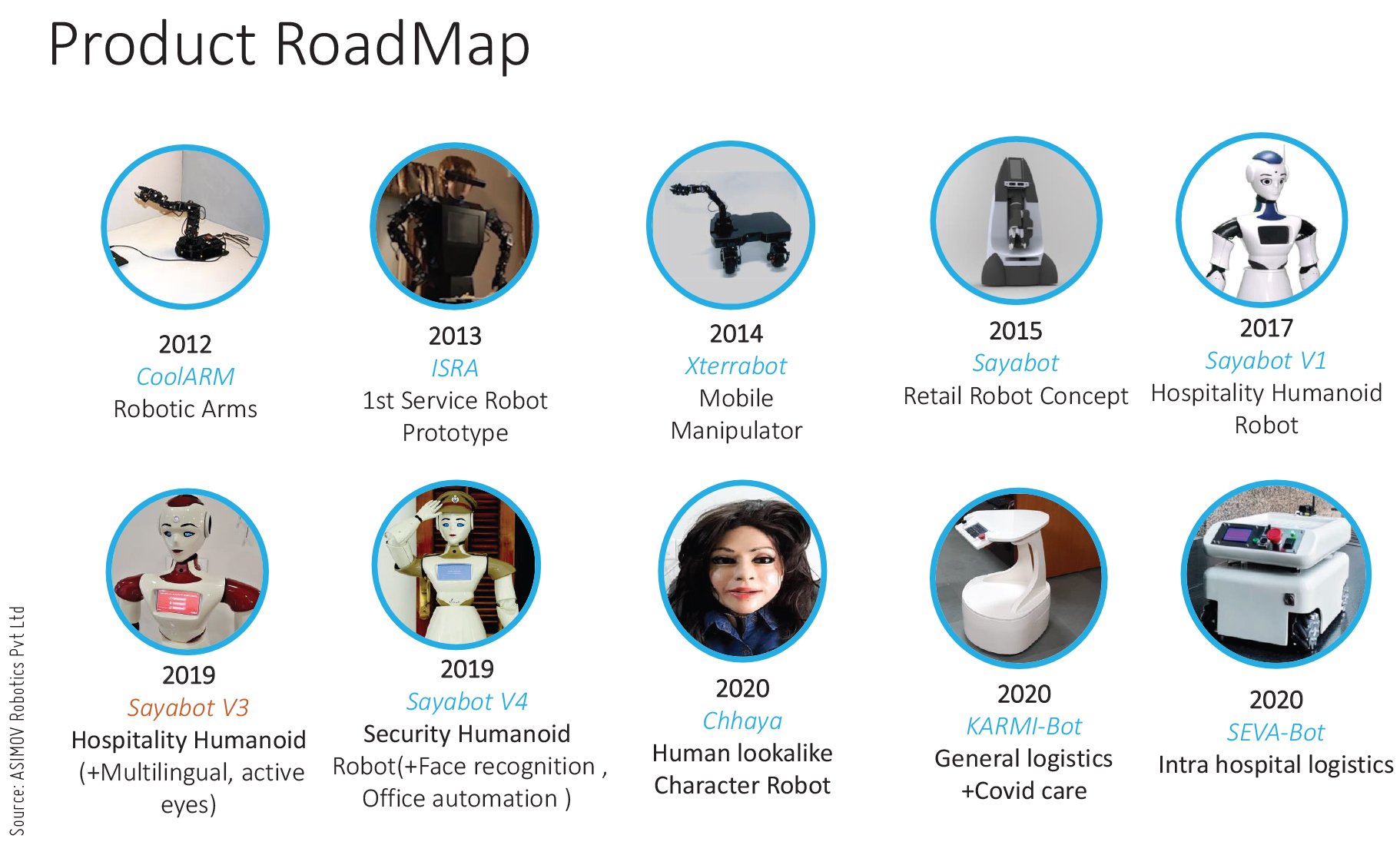

By 2012, the team, having disassociated with the US firm, then incorporated ASIMOV Robotics to focus on developing service robots and release India’s first humanoid robot ISRA (Intelligent Service Robot Assistant), capable of cooking and serving a few selected popular dishes on its users’ request.

Since the Indian market was not ready at the time, the company started developing test automation systems and supplied products to most Indian IT companies. “By 2016, the service robot market in India started responding. We had released the first Indian robot for banking lobby management named SAYABOT,” he adds.

Being a highly customizable robot, SAYABOT became remarkably successful to be able to get deployments in BFSI, Security and Hospitality, and Healthcare applications. By 2019, India’s first police robot KP-BOT, a version of SAYABOT was launched at state police department headquarters which is currently serving as lady sub-inspector there.

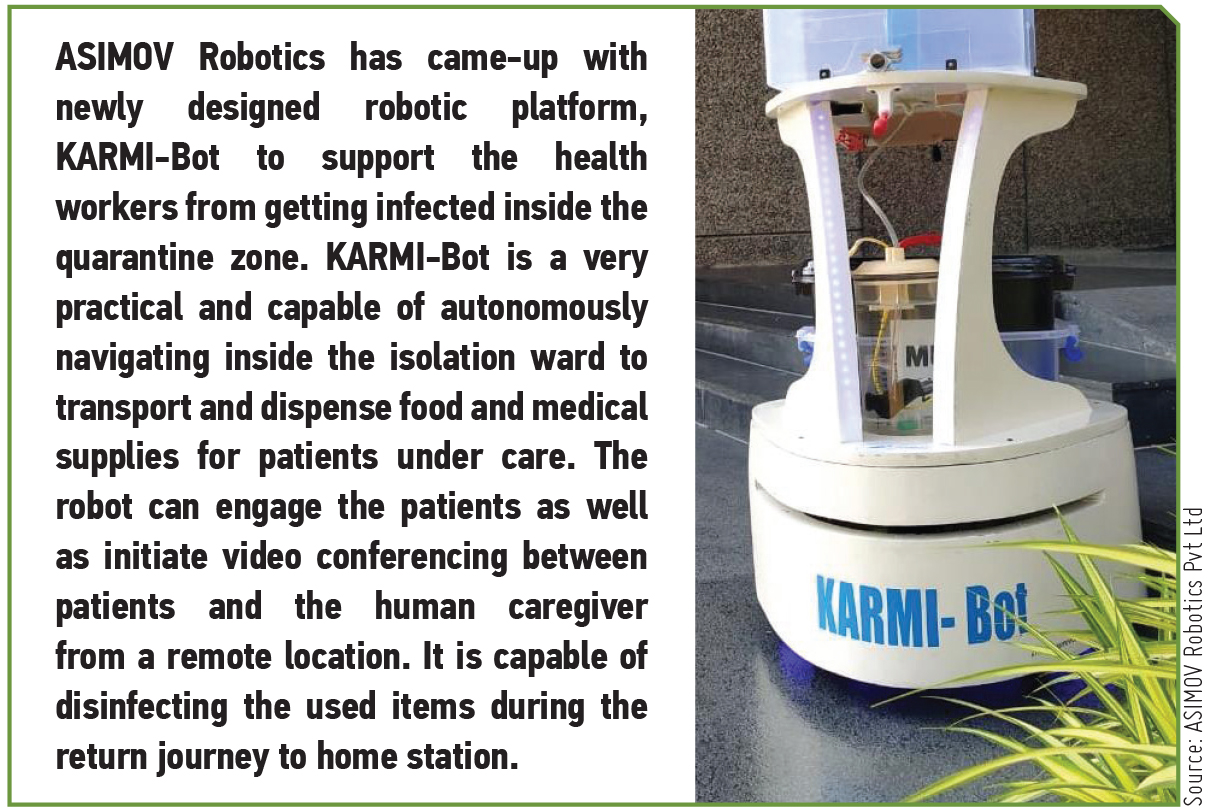

“By the end of 2019, we started concentrating in Healthcare applications along with the second outbreak of Nipah in Kerala. However, this initiative helped us in quickly deploying a fully autonomous robot, KARMI-Bot for serving food and medicines to Covid-19 patients at the government hospital in Kochi during the initial days of Pandemic,” he informs. Today, the company is developing a range of products for Covid-related issues.

Asimov Robotics developed the first Indian multi-purpose humanoid service robot, SAYABOT.

The form factor, appearance and behaviour of SAYABOT are similar to that human beings.

Products that spell innovation

Of the wide range of products, the company’s main revenue spinners are SAYABOT and KARMI-Bot. With recent developments in AI, we are seeing the advent of intelligent robots that can perform tasks like that of a human. There is a rising demand globally for human-like robots that can perform tasks such as information assistance, delivery and surveillance. With SAYABOT, ASIMOV Robotics became the first Indian multi-purpose humanoid service robot. The form factor, appearance, and behavior of SAYABOT are similar to that of human beings. It is a versatile robot that can be customized to perform tasks in various sectors such as Hospitality, Security, Retail, Healthcare, Education, and Banking. “With AI and a range of sensors collecting information of the environment, SAYABOT can work alongside humans seamlessly,” informs Jayakrishnan.

Robots in the medical space

The medical community, says Jayakrishnan, has been incredibly supportive and encouraging when the ASIMOV team approached them with its prototype in March 2020. “We had to first approach the district health administration, the RMO, and the team heading the Covid-19 treatment at the Government Medical College in Kochi. We then realized that serving food and medicines inside the Covid ward was not enough, collection of trash and used items and frequent cleaning and disinfection, etc. was also needed,” he shares.

Needful modifications for KARMI-Bot were made for it to do additional duties such as collection and disinfection of trash using UV light. The robot has been ruggedized and weatherproofed so that it can be cleaned using detergent spray after every visit. Since then, KARMI-Bot has been successfully serving Covid patients for the past months at Cochin Medical College.

Recently, the company also received `48 lakh from the central government for research on a minimal invasive cutting technology for craniostenosis—a condition that affects the skull development of a foetus. Elaborating on the venture, he shares that ASIMOV Robotics has been approached by Dr Derick A Mendonca, Consultant Craniofacial Plastic Surgeon, Sakra World Hospital, Bangalore. “The proposal is to develop a minimally invasive micro-robotic system which can perform locomotion under the scalp and separate the sutures prematurely fused,” he adds.

The initial idea of localizing and navigating the robot under the scalp was using the Stereotactic method. Based on this reference and a provisional patent filed, the company was asked to design and develop the mechanical system and control algorithms to perform the surgery minimally invasively.

The system consists of a cutting mechanism with a camera, a suction-irrigation system and a retractor to protect the dura mater. Due to manufacturing difficulties, this necessitated the scaling of the unit and also separating the navigation from the cutting unit to be able to work with scaled-up skull models. This project has been funded by DST and is still in the process of refinement and miniaturization.

Why Robotics and Automation Solutions

“All the automation or robotization requirements are not necessarily to reduce the cost of labor. Based on each industry, it optimizes a parameter or a set of parameters,” explains Jayakrishnan.

“For example, in the Manufacturing industry, the goal is to boost production throughput and the quality of work. In surgery, accuracy is to be increased and lead time for recovery must be reduced. In certain other places, the risk of humans in hazardous tasks has to be reduced,” he adds.

While automation of repetitive jobs aces in terms of efficiency, automating mundane jobs addresses the shortage of resources, and automating default jobs helps save human lives.

“However, the Indian market is not yet matured to include robotics as an unavoidable part of the workforce due to a high initial cost and delay in identifying possibilities due to the lack of knowledge. Hence, the other possibility in this scenario is introducing semi-autonomous systems,” he notes.

Despite all constraints, according to him, early adaptors to these technologies have a huge advantage of minimizing expense in switching over to autonomous systems. At a later stage, others may require many folds of investment as their existing systems and practices will not comply with the autonomous approach.

Recently, the company received `48 lakh from the central government for research on a minimal invasive

cutting technology for craniostenosis—a condition that affects the skull development of a foetus.

“Early adaptors also get an edge over their competitors in scaling their business while delivering the solutions with the required level of quality and price as the market demands,” he says summing up.

Source: ASIMOV Robotics Pvt Ltd

Poonam Pednekar

Chief Copy Editor

Magic Wand Media Inc

poonam.pednekar@magicwandmedia.in

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe