EXPLORING POSSIBILITIES

Modellbau Clauß and DMG MORI’s association dates back to the early 2000. The trust built over the years made the former invest in a 3D Printing machine, bringing in numerous benefits such as production of metal prototypes…

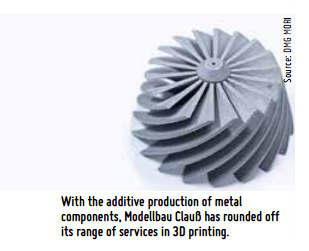

Modellbau Clauß GmbH & Co. KG, founded in 1948 in Neukirchen near Chemnitz in Germany, has its origins in the production of foundry patterns. Initially the patterns were made of wood, later of plastic and then, with the advent of the first CNC machine tools, also of metal. The range today also includes moulds and prototypes. The family business with 45 employees supplies customers from the Automotive, Machine Building and Plant Engineering sectors. Modellbau Clauß has been working with turning and milling machines from DMG MORI since 2003. In 2018, the company invested in 3D printer a LASERTEC 30 SLM 2nd Generation for additive production of metal components.

The combination of 3D printing with DMG MORI 5-axis machines allows high-precision metal cutting of additively manufactured components that cannot be produced in a conventional way.

“With regard to the production of models and prototypes, we benefit from ongoing development of 3D printing,” states Ulli Clauß. Together with his brother Rico Clauß, they are third-generation managers and have added this technology to the company’s production department. “Following the first 3D printers for plastic models, we quickly recognized the potential for the production of metal prototypes,” Rico adds.

New potential and new component geometries using the powder bed process

The five machine tools from DMG MORI at Modellbau Clauß now also involve 3D printing. “The LASERTEC 30 SLM 2nd Generation ideally complements our machinery,” says Ulli approvingly. With the powder bed machine, highly complex and filigree components made of materials such as aluminum or steel can be produced in a footprint of 300 × 300 × 300mm. “Such geometries cannot be realized subtractively,” he adds. The combination of 3D print-ing with DMG MORI 5-axis machines allows high-precision metal cutting of additively manufactured components that cannot be produced in a conventional way.

In such complex geometries, Rico and Ulli see the great added value of selective laser melting in a powder bed. “It enables highly complex component requirements to be met and new business fields to be opened up,” shares Rico. Moulds for producing carbon fiber wheel rims are a current example. “Thanks to the LASERTEC 30 SLM 2nd Generation, we can now realize the required conformal cooling channels,” he adds.

rePLUG – Safe material changeover in less than two hours

Modellbau Clauß has purchased the LASERTEC 30 SLM 2nd Generation with a total of three rePLUG powder modules. “Therefore, we always have different metal powders on hand,” Ulli explains. An operator can change the individual modules in less than two hours, of course without contamination. Rico also sees an advantage in the closed material cycle: “This means we have absolutely safe powder handling.”

Modellbau Clauß uses a microscope to check the structural density of the workpieces created in the powder bed.

The workpieces are programmed externally and transferred to the CELOS APP RDesigner.

User-friendly CAM programming from the CAD data is carried out.

The LASERTEC 30 SLM 2nd Generation is equipped with DMG MORI's proprietary control and user interface, CELOS.

CELOS as an innovative and integral software solution

The LASERTEC 30 SLM 2nd Generation is equipped with DMG MORI's proprietary control and user interface, CELOS. Geometrically highly complex components can be programmed quickly off-line and transferred to the machine. “The process is a completely open system. In other words, all machine settings and parameters can be adapted individually,” says Ulli, giving an insight into the day-to-day use of the machine. CAM programming is carried out in the CELOS APP RDesigner based on CAD models. Heat calculation is also integrated. It calculates the mass distribution in advance and automatically adjusts the laser parameters. The CELOS APP JOB CONTROL supplies all relevant machine and job parameters including camera-based tests and error detection of each individual component layer.

New service thanks to know-how in additive manufacturing

With experience in 3D printing, especially in the powder bed process, as well as upstream and downstream process steps such as design and post-processing, Modellbau Clauß is building a future for the company. Additive manufacturing has not yet arrived in all development departments, says Ulli: “We would like to show our customers the design freedom that is possible and support them in optimizing their components with the help of additive manufacturing.”

Even the most filigree geometries can be realized effortlessly in the powder bed process

Source: DMG MORI

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe