Snow-jet Technology : For Ideal Coating Results

Due to higher quality standards, increasingly complex component designs, as well as modified coating materials and layer structures, cleaning plastic automotive parts in flatbed coating lines is becoming a major issue. OEMs too are increasingly demanding automated cleaning processes. Suitable for Industrie 4.0 applications, the quattroClean snow-jet technology meets these demands with ease.

Regardless of whether it is classical spray painting with water-based or solvent-based paints, fast-drying UV paints, PVD coatings or laser paints for day/night designs – today there are more ways than ever of adding decorative, functional and individual features to plastic interior parts destined for the automotive industry. However, quality standards for coatings have also never been so high. For this reason, cleaning parts before they are coated is becoming an ever-more crucial process for conventional flatbed coating lines. This is because the cleanliness of the surface to be coated decisively affects coating results. It is, therefore, no wonder that an increasing number of vehicle manufacturers expect the specifications for such components to include an automated cleaning process..

Space-saving, dry cleaning system

A conventional power wash system that uses an aqueous cleaning medium and a downstream water dryer has its limits. On the one hand, the process is expensive, energy-consuming and takes up a lot of space, making it expensive as far as costs are concerned. On the other hand, liquid residues are sometimes still present when parts reach the coating line, which impairs coating results. Consequently, some coating line manufacturers see the environmentally-neutral CO2 snow-jet cleaning system quattroClean from acp GmbH as an alternative. The system uses a dry, residue-free process to clean the areas of parts requiring coating in-line. Its compact design, as well as the flexible supply options for carbon dioxide and compressed air, makes it easy to integrate the cleaning module into new or existing coating lines. Depending on the requirements of the coating process, the coating line manufacturer or operator decides whether the system should be mounted onto an existing axis or integrated into a robot.

For applications in flatbed coating lines, one or more nozzle arrays are used depending on requirements. The consistent power of the jet over the entire cleaning surface guarantees uniform results.

Reliable with uniform cleaning results

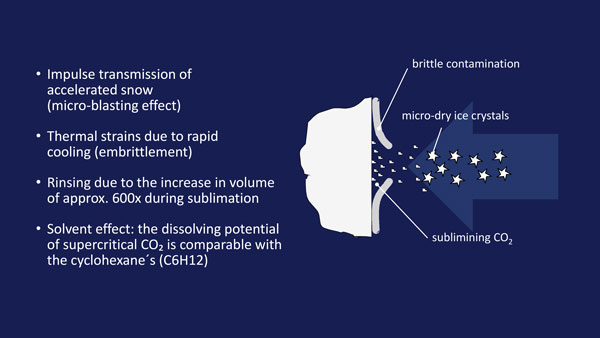

Since it is generated as a by-product from chemical processes as well as from the production of energy from biomass, the liquid carbon dioxide used in the cleaning process is environmentally neutral. Non-combustible, non-corrosive and non-toxic, the carbon dioxide is fed through the non-wearing two-component ring nozzle of the acp system and expands on exiting to form fine CO2 crystals. These are then bundled by a circular jacketed jet of compressed air and accelerated to supersonic speed. The impact of the non-abrasive jet of snow and compressed air on the surface to be cleaned at a temperature of minus 78.5°C triggers a combination of thermal, mechanical, sublimation and solvent effects. These four cleaning mechanisms enable the quattroClean system to reliably remove filmic contamination, for example residues of separating agents, silicones and fingerprints, as well as particulate airborne contamination, such as dust and fluff. When integrated into a flatbed coating line, one or more nozzle arrays are used depending on requirements. The jet is applied evenly to the complete area to ensure a uniformly clean surface. And in a quality that gives first class results, even when it comes to sophisticated coatings such as piano lacquers.

Thanks to the aerodynamic force of the jet, the detached contamination is carried away and removed by an integrated extraction unit to prevent recontamination. Since CO2 sublimates instantly at atmospheric pressure, components are dry at the end of the cleaning process and are ready for ionizing or coating straightaway.

Customized application

The modular design of the quattroClean system means that it can be tailored perfectly to requirements. All process parameters, such as flow rates for compressed air and carbon dioxide, the angle of the jet and motion sequences – including three dimensional movements – can be specifically adjusted to the part requiring coating and filed as a cleaning program in the controller. The effective range of the nozzle array is also automatically scalable to workpiece geometries. With this degree of flexibility, whole surfaces - or just specific areas - even of delicate parts are cleaned effectively, while simultaneously minimizing the consumption of compressed air and carbon dioxide.

The cleaning system is also suitable for Industrie 4.0 applications; via interfaces such as Profibus, it can be linked with the control unit of the coating line or production planning system. This enables the production facility to function fully automatically without any need for manual intervention.

Thanks to its reliable cleaning process tailored to the geometry of components, as well as the ability to integrate it into an existing flatbed coating line, the quattroClean system from acp goes a long way towards meeting today’s high coating standards. At the same time, it offers great potential to make coating and painting processes more cost-effective and gentler on resources.

Author

Doris Schulz

Journalist (DJV)

SCHULZ. PRESSE. TEXT.

ds@pressetextschulz.de

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe