Implementing Favorable Changes

Despite the adoption of automation in the Indian manufacturing space on the rise, there are many who remain unaware of the benefits that accrue it. Here’s a few kinds of automation solutions from Felsomat India that can be of immense help in boosting productivity, saving costs, improving quality and staying competitive.

Indian manufacturing has evolved considerably over the last decade after several leading global automotive manufacturers set up their production base in India. The high growth in the production and sale of two wheelers in India has also made automation viable in the autocomponent manufacturing. Additionally, operator safety and fatigue has gained prominence in the last few years, necessitating the move towards the use of automation for hazardous and strenuous production activities.

Indian manufacturing has evolved considerably over the last decade after several leading global automotive manufacturers set up their production base in India. The high growth in the production and sale of two wheelers in India has also made automation viable in the autocomponent manufacturing. Additionally, operator safety and fatigue has gained prominence in the last few years, necessitating the move towards the use of automation for hazardous and strenuous production activities.

Why Adopt Automation

Generally speaking, following are some of the key factors that make automation in manufacturing crucial:

- When dealing with heavy components: Manual loading is difficult and the loading time is very high as compared to the machining time;

- When cycle times are very low: Frequent loading leads to operator fatigue and loss of production;

- While working with high-cost or critical machines where the loss of production is not acceptable;

- For minimizing manpower and maximizing production;

- For replacing aged and unproductive workforce;

- For increasing reliability of output and removing dependence on operator efficiency, absenteeism etc.;

- For enhancing output from existing machines instead of investing in a new line;

While working on a bottleneck machine.

Automation Types

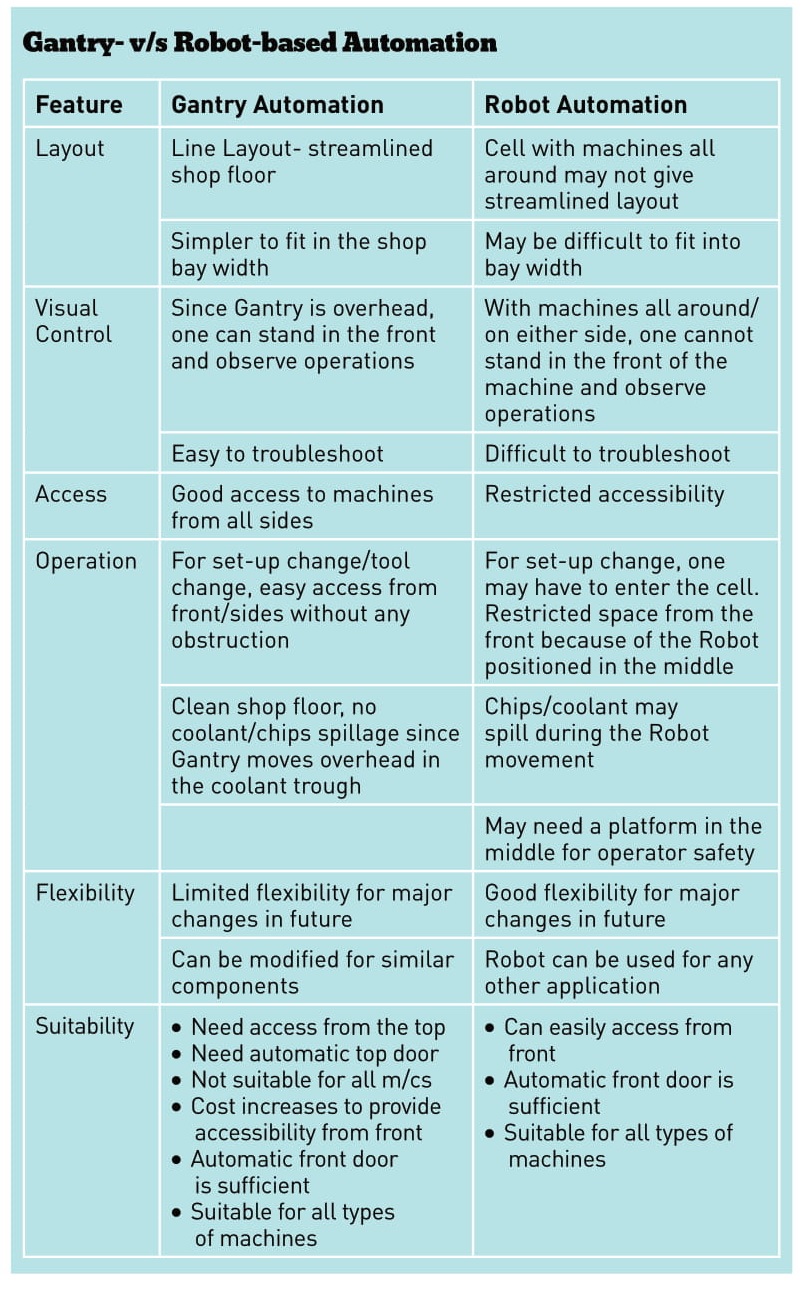

Machine tending automation can be broadly categorized into Gantry-based automation and Robot-based automation.

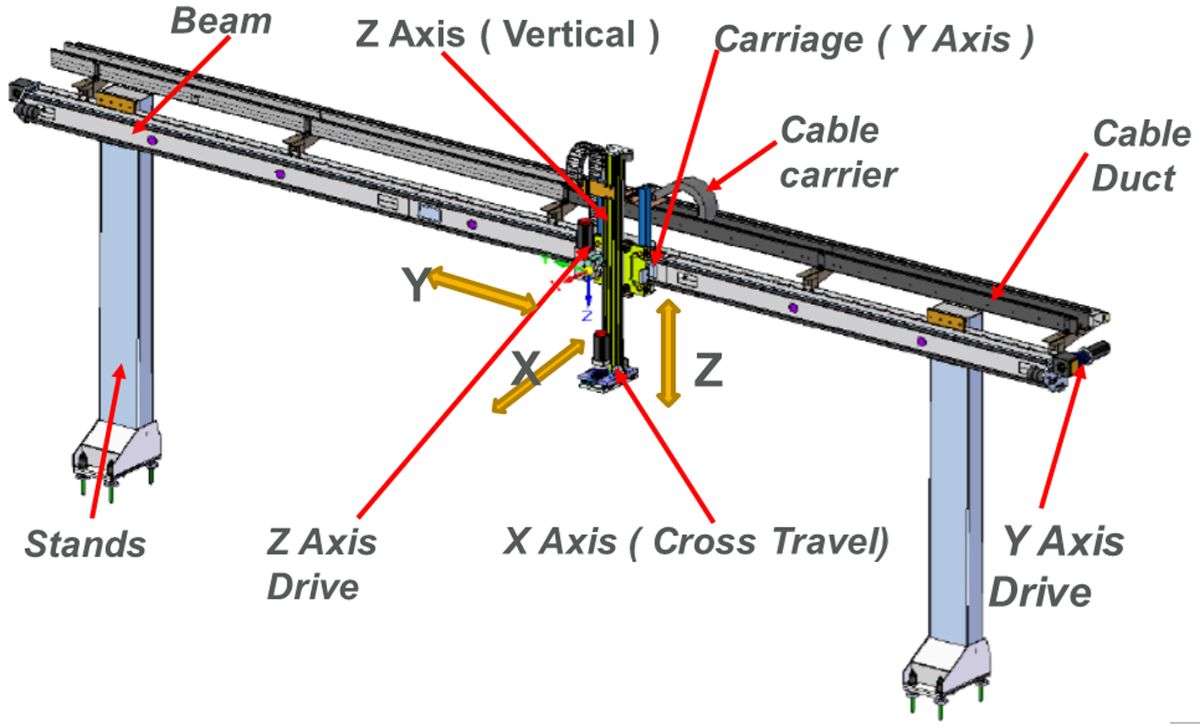

Gantry-based automation has the following features:

- Machines to be automated are arranged in a line;

- The Gantry system is positioned overhead above the machines;

- It requires access from the top of the machines to reach the fixtures for load/unload;

- Separate automatic top door is required in the machine;

- Typically, it is a 2/3 axes system but it can have more axes if required;

- The arrangement of Raw parts supply/Finished parts receipt can be at one end or at both ends or in between depending on configuration/customer requirement;

Gantry is controlled by a CNC system.

The features of Robot-based automation include:

- A standard Robot from any manufacturer can be used;

- Depending on the application, the Robot can be: SCARA Robot, Fixed Robot with 6 axes, Floor track mounted Robot with 7 axes, or Overhead Gantry mounted Robot with 7 axes;

- In the case of Fixed Robot application, machines are arranged around the Robot, including the raw part supply/finished part receipt;

- In the case of Floor track mounted or overhead Gantry mounted Robots, machines are arranged on both sides in a line including the raw part supply/finished part receipt;

- The Robot is controlled by its own controller;

A separate PLC is used for controlling cell operations.

Customer check-list

Implementing automation solutions requires extensive discussion between the customer and the automation supplier.

Not only the automation provider has to ensure a reliable system, the manufacturing customer also has to ensure that he has taken care of critical requirements from the manufacturing process side for successful automation. Some of the points to be taken care are:

- Fixture to be clean from chips for new part loading. If otherwise, this can cause frequent interruptions;

- If machining involves close accuracy, then seat check is a must;

- Fixture should provide good accessibility to grip the part;

- Process and tool reliability must be ensured. Tool breakage sensing/tool monitoring must be provided if the tool is prone to breakage;

- If existing machines are to be automated, then the reliability of machines is important;

- Frequency for the inspection of components has to be predetermined so that the components are automatically brought out of line for inspection;

- If required, the inspection equipment can be integrated in automation line with or without auto feedback and correction in the machines;

Handling of rejected parts, post inspection or seat check failure etc. should be defined and automated.

Every automation solution is unique

Automation is a specialized activity that aids in increasing the output from the line/cell. Hence, experienced automation suppliers are the best fit to fulfil all the requirements and provide a stable solution. In India, many manufacturers are hesitant to take up automation as they are not clear in quantitative terms about the benefits that accrue from proper automation, and hence, are not in the position to justify the ROI from the investment. But if implemented properly, the returns from automation far exceeds the investment over a period of time and also frees the production team from the stress of daily variability in output and meeting the scheduled production targets.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe