Artificial Intelligence in Industry 4.0

The factory of the future is versatile, safe and uses resources in an optimal way to manufacture anything from single products to mass series. Such flexibility requires a high level of maturity as far as Industry 4.0 is concerned: In hybrid teams, humans work hand-in-hand with robots and are supported in their activities by intelligent assistance systems.

The German Research Center for Artificial Intelligence (DFKI) was founded in 1988 as a non-profit public-private partnership. In the field of innovative commercial software technology using Artificial Intelligence (AI), DFKI is the leading research center in Germany. Based on application oriented basic research, the center develops product functions, prototypes and patentable solutions in the field of information and communication technology.

DFKI is one of the main co-founders of Industry 4.0, the so-called 4th industrial revolution brought about by the integration of modern information and communication technologies into the production process. The use of AI in Industry 4.0 presents both opportunities and hurdles for real-world production facilities. All too often, inadequate digitization in companies and establishments combined with poor data quality stand in the way of a rollout of innovative technologies.

Digitalization ‘with rhyme and reason’

Unfortunately, digitalization and Industry 4.0 are often confused with each other. But it is important to be very clear in distinguishing them precisely: there is no Industry 4.0 without digitalization.

Today, we are in the middle of the second wave of digitalization. The first wave was about digital data and how to record, store, transmit and process it to enable machine-readable data for the Internet and cloud technologies. Nowadays, digital data must become machine-understandable, refinable data for active usage in AI and Machine Learning systems and applications as a base for (new) business models (e.g. smart services) and monetization.

A digitalization ‘with rhyme and reason’ leads from (Big) data to Smart data and meta-knowledge – Data mining, the systematic application of statistical methods to large amounts of data (in particular ‘Big data’ or mass data) – with the aim of identifying new cross-connections and trends. Information extraction generates knowledge, which can then be used for meta data reference systems, leading to digital understanding.

The meaning of digital understanding is two-fold: Understanding digital data and understanding with the help of digital systems. Examples are understanding written text, spoken language, images, videos, or sensor data with the help of AI on digital computers that lead to adequate results, e.g. in terms of answering questions based on texts, videos or sensor values, or a physical reaction of robots or networked devices.

Industry 4.0 readiness

It is crucial for companies to have a deep insight in their degree of digitalization and Industry 4.0 readiness in order to take appropriate decisions for their development. For this task of Industry 4.0 maturity assessment of production, several indices have been created. Increasing levels of maturity may be computerization, connectivity, visibility, transparency, predictability, and adaptability. A maturity index developed by the German FIR institute, together with DFKI and other partners, follows an assess and assist approach that enables companies to set up specific, benefit-oriented I4.0 roadmaps. This approach takes into account the four different structuring forces of companies: information systems, resources, organizational structure, and culture for an enterprise-wide assessment.

The assessment examines relevant core processes of a company and consists of three phases. Evaluation and recommendation are based on the surveys conducted at the enterprise. The results of the survey are transferred and combined to the maturity level radar for the four structuring forces. The analysis of this combined radar identifies the functions and structuring forces where capabilities have to be expanded. It allows for a clear vision of what has to be targeted next by deriving action items for a transformation roadmap to Industry 4.0.

Intelligent software systems

Given a sufficient degree of digitalization as described before, intelligent software systems based on knowledge processing can be employed with AI entering the scene. Being a part of Computer Science, with its aspects of Computational Science and Engineering, AI has also strong links to Cognitive Sciences and, therefore, integrates insights from Linguistics, Biosciences, Psychology, and Philosophy. AI is meant here as Avantgarde Informatics and, in this sense, describes realizing intelligent behavior and the underlying cognitive abilities on computer systems. Knowledge processing covers retrieval, extraction and inference of knowledge as well as its presentation and distribution. Core aspects are the representation and the management of knowledge, deployed by discovery, learning and teaching of (inferred) knowledge. At present, in cognitive systems, we often use hybrid architectures: knowledge bases combined with Machine Learning.

Today’s rapidly developing IT environments like Web and Cloud technologies, in-memory computing, and GPU parallel cluster as well as mobile internet, 5G, and Big Data boost AI solutions. Combining AI with Smart Data creates (new) smart products and services. Being collaborative, autonomous, proactive, interoperable, adaptive, self-healing, self-explanatory, self-learning, self-optimizing, and fault-tolerant are the key features of AI systems.

Industry 4.0 based on AI

The key aspects of Industry 4.0 based on AI for the Internet of Things (IoT) must cope with the needs of the manufacturing industry to increase efficiency, handle batch size 1, and apply to the multi-adaptivity required. According to and adapted from Siemens, these needs can be clustered into four core aspects: Modularity, Connectivity, Autonomy, and Digital Twin. Smart Factories are defined by several factors that refer to these core aspects: Dynamic networks of local controllers and anytime planning in real-time are needed for a flexible production configured in response to rapidly changing processes. Self-organization lead to an optimization of production, e.g. through Cyber-Physical Production Systems. Digital Twins of the entire process and its constituent elements are essential to monitor components and results, even simulated in advance, to plan in detail the start-up of a new asset, product or line.

Complex AI systems cope with these manifold requirements by the idea of ‘AI on Demand’: AI components (‘building blocks’) for sensing, understanding, and acting work together in complex systems. Here are some examples of AI technologies for Industry 4.0 characteristics :

Semantic Service Matching for Mass Customization

- Machine Learning for Predictive Maintenance

- Ontology Merging for Plug & Produce

- GPU-based Anytime AI Planning Algorithms for Real-time Line Balancing

- Deep Learning, and Active Sensor Fusion for Online Quality Control

- Semantic Product Memories and further Semantic AI Technologies for the Digital Twin

- Plan Recognition, and User Modelling, AR/MR/DR for Worker Assistance

- Deep Learning for Process Anomaly Detection

- Multiagent Planning, BDI (belief–desire–intention) Architectures for Hybrid Teams

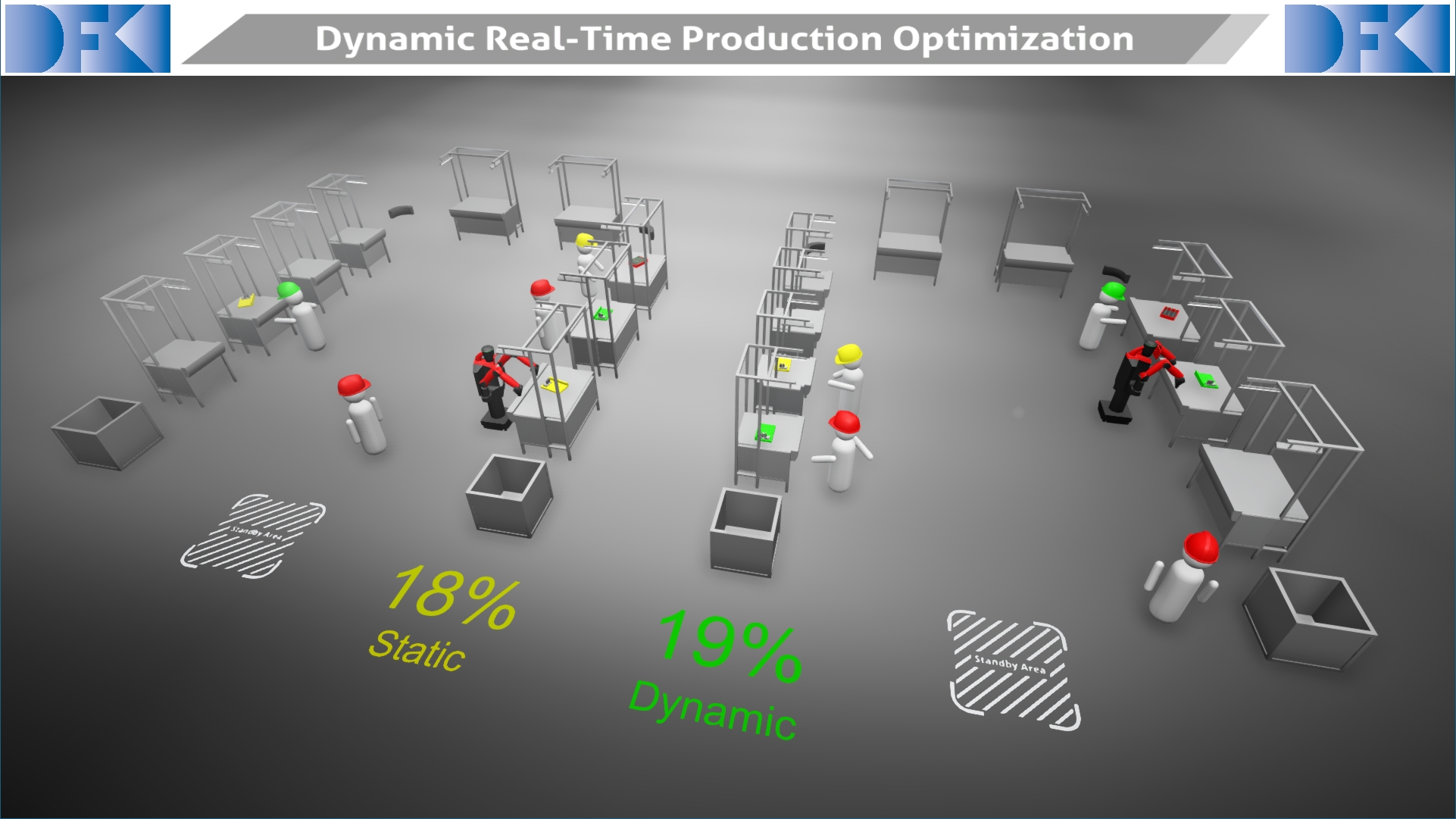

In this context, the DFKI research department ‘Cognitive Assistants’ present a system for planning and optimizing

production systems on-the-fly in real-time. In collaboration with various industrial partners, the system is currently being validated under real conditions.

Here, we choose optimization approach based on GPU computing for Extremely Large State Spaces. Besides generic Optimizer Library designed for GPUs that make available the generic functionality required by all optimizers, on the domain side specific knowledge (a domain model) as well as state descriptions, optimization goals, and exploration heuristics are essential.

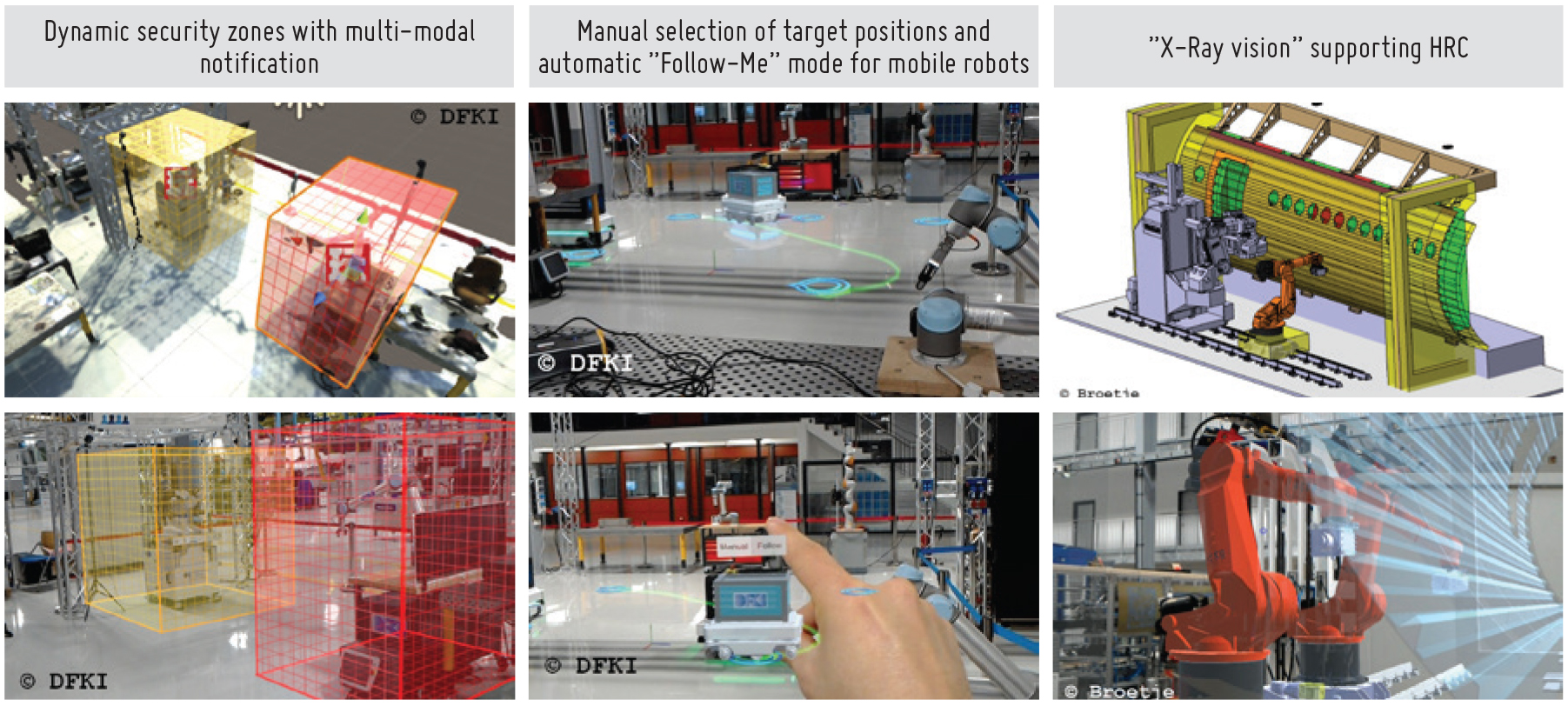

Let me give you another example: Robots will no longer be locked in safety work cells but collaborate with human workers in the same place at the same time on the same asset. (Yes, this will take some more time to become common.) A new generation of light-weight, flexible robots will collaborate with humans in the smart factory. HRC (Human Robot Collaboration) modules as assistance systems based on AI allow for an ‘X-Ray’ view through the workers’ HoloLens for tracking dangerous actions of occluded heavy-weight robots. Hybrid teams of human workers and robots apply for multi-adaptive manufacturing tasks.

BaSys 4.0

The joint German reference research project, BaSys 4.0 aims at building a software infrastructure for Industry 4.0, which also supports production-relevant change processes. Main building blocks are the so-called Asset administration shell (Digital Twin), Structured (semantic) domain models, and a Service-oriented production concept. BaSys 4.0 provides an open source reference implementation. Its service-oriented production approach covers three layers: The orchestrated production process specifies the required resource capabilities, the asset administration shell of device provides uniform service interface for access to capabilities, while Powerline Communication (PLC) functions realize the pure skills (not the production logic). All services participate in the same distributed service platform via communication APIs and a uniform service structure.

Conclusion

AI technologies are a key success factor for Industry 4.0. Semantic technologies guarantee interoperability in multi-vendor factories and are the basis for a disruptive SOA production logic. GPU-based automated production planning in real-time is a breakthrough for flexible automation. User Modeling, Plan Recognition as well as Intelligent Multimodal Interfaces are the basis for a new generation of worker assistance systems. Hybrid teams of cobots, softbots and people are a challenge for basic research in multi-agent coordination, e.g. with an acceptable solution of the transfer of control problem. Industry 4.0 brings many AI subfields together in one of the most important fields of industrialized countries like Germany. But the base line is that there is no Industry 4.0 without digitalization.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe