Debuts at EMO

The CHIRON Group is appearing at EMO with a lot of debuts: new machining centers, software and automation solutions.

CHIRON: new variants of the 16 series and DZ 25 P five axis

The new FZ 16 S five-axis combined with VariocellPallet pallet automation is aimed at machining small batch sizes and complex workpieces autonomously. The new DZ 16 W five-axis will be presented live in action in Hannover.

The CHIRON DZ 25 P five axis is designed for productive machining of large components in the automotive industry and aviation. With a spindle distance of 800 mm, the DZ 25 P five axis is predestined for double-spindle machining of aluminum structural components.

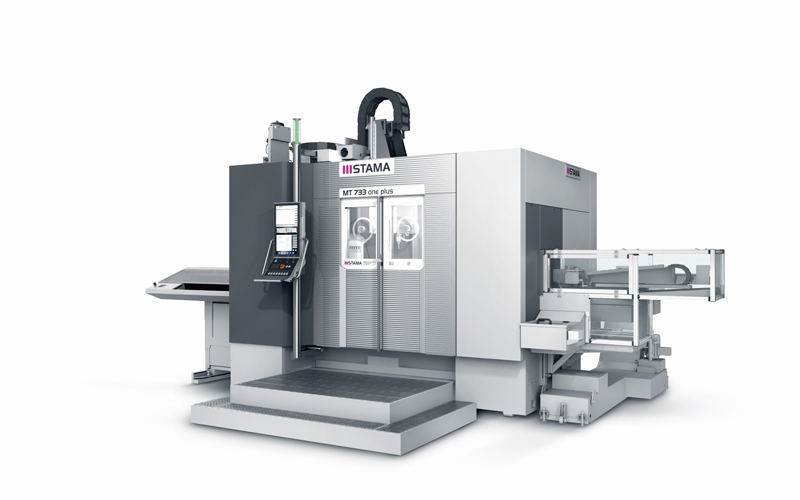

STAMA MT 733 one plus – complete machining for complex workpieces

Like all models of the MT 733 series, it has a gantry design: this allows the machining process to gain a significant amount of stability on a thermal, mechanical and static level. The Galaxie® drive system in the B-axis bolsters this effect with its extreme power density, stiffness and positioning precision.

MT 733 one plus: Complete machining of complex components and difficult-to-cut materials.

The SmartLine modules ensure process reliability, higher productivity and production optimization.

Vertical turning from SCHERER

The VDZ 320 is a multi-functional vertical pickup turning machining center. The series can be precisely tailored to the customer’s requirements. Options include another milling spindle and special modules for ball turning, bearing track milling and hobbing.

CMS presents automation solutions that can be retrofitted

Retrofit specialist CMS is showing how an outdated machining center can be enhanced by a modern automation solution and how this can significantly improve productivity.

SmartLine software portfolio extended

This year, the CHIRON Group is extending its SmartLine program with ConditionLine and ProtectLine. The software modules can be implemented individually or together. ConditionLine allows precise planning of maintenance work and repairs. ProtectLine has a preventative function in protecting physical machining centers from collisions with help from a digital twin. The virtual machining center always runs ahead of the real one and shuts it down in good time if there are any collision risks.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe