LEADING THROUGH INNOVATION

WIDMA® Machining Solutions Group of Kennametal India Ltd has once again proven its mettle, earning the IMTMA ‘Best Design Award 2025’ for its Blank Profile Grinding Machine BPG-15. This accolade highlights the company’s dedication to innovation and precision engineering, raising the bar in metal cutting and grinding technology.

“We are truly honored to receive this recognition,” said Vijaykrishnan Venkatesan, Managing Director, Kennametal India Ltd. “IMTMA offers a prestigious platform that unites the top players in the Machine Tool industry to showcase their latest advancements, creating a highly competitive environment.”

“This makes the recognition even more meaningful and special to us. It stands as a testament to our ability to develop state-of-the-art machines that not only address the current needs of our customers but are also engineered to meet their future requirements.” he further explained.

Advancing Technology with User Feedback

According to Venkatesan, “WIDMA’s commitment to innovation emanates from a customer-centric mindset. Our customers’ feedback plays a crucial role in shaping our new product development strategies that address their challenges and provide them with a competitive edge.”

“Backed by our all-in-one, state-of-the-art manufacturing facility, our new product development team is continuously working to expand our portfolio,” Venkatesan shared. “Today, we offer a highly diversified assortment of machines, right from special purpose machines, horizontal machining centers, vertical turning lathes, and deep hole drilling machines to tool & cutter grinding machines, as well as fixture and tooling solutions through the ‘WIDMA’ brand.”

BPG-15: The Evolution of Precision Grinding

The journey towards developing the BPG-15 began with a deep understanding of industry processes and pain points. “As it goes with any new product launch, the first milestone in the journey was understanding the prevailing process in the industry on blank preparation,” Venkatesan explained.

Currently, most carbide round tool manufacturers rely on manual cylindrical grinding machines for outer diameter (OD) preparation and the formation of steps and profiles on blanks. These preformed blanks then serve as inputs for CNC tools and cutter grinding machines to manufacture the finished tool. Recognizing the growing demand for round tools, the company realized the need for automation and benchmarking with advanced operations like in other countries.

What Sets the BPG-15 Apart?

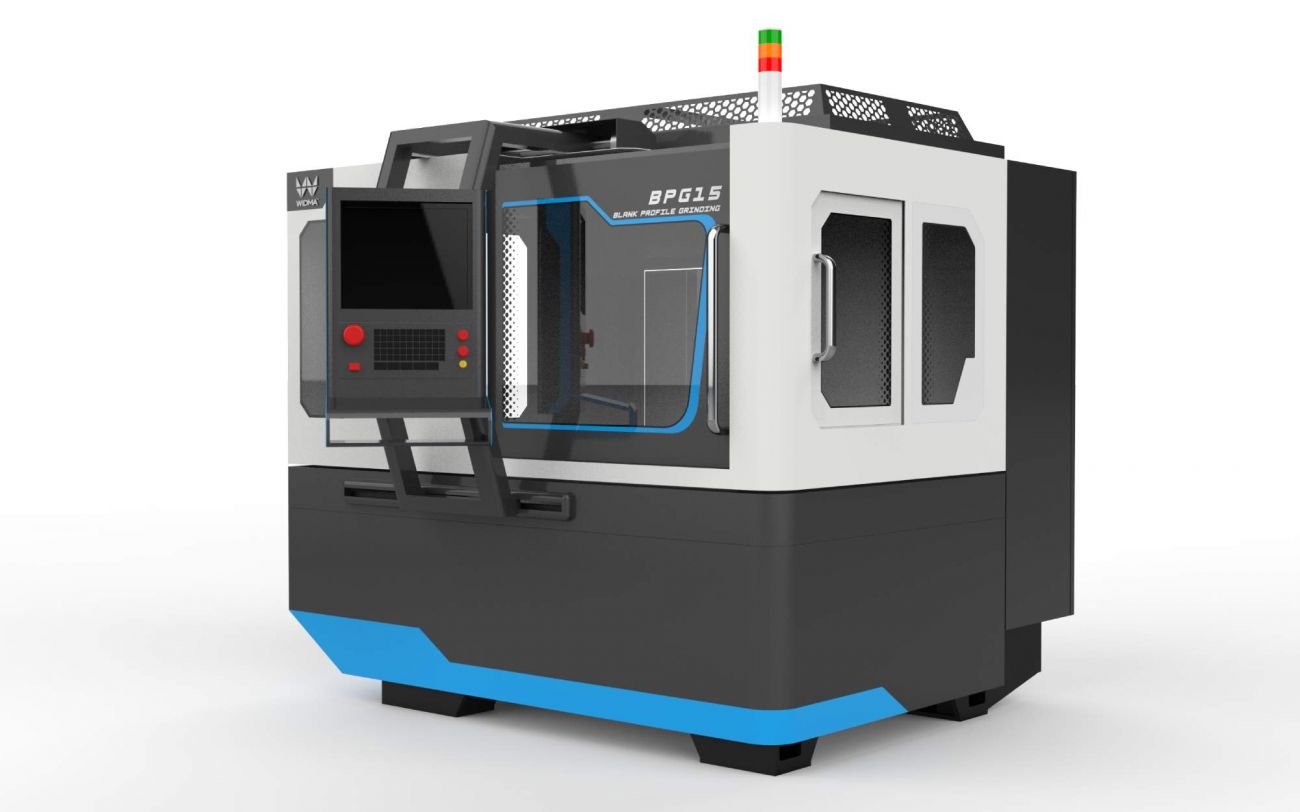

WIDMA’s BPG-15 is not just another grinding machine—it is a breakthrough in precision engineering and automation. “WIDMA’s new Blank Profile Grinding Machine is specially designed with high axial force linear motors for all linear axes, dedicated to the preparation of cutting tool blanks (dia 0.4 mm to 32 mm) in one setup,” Venkatesan highlighted.

The BPG-15 is equipped with eBlank software, offering a user-friendly interface for grinding tool blanks with greater efficiency. More importantly, it replaces traditional ball screws with high axial force linear motors, significantly reducing maintenance requirements while enhancing performance.

“This innovative design also minimizes the number of machines and fixtures required, consolidating multiple operations into a single, efficient unit,” he added. “Additionally, its IoT compatibility adds a layer of intelligence, enabling smarter monitoring and control. Built to global standards, the machine offers superior quality and incorporates advanced safety and automation features such as auto loading and unloading.”

|

WIDMA® Machining Solutions Group of Kennametal India Ltd received the IMTMA Best Design Award 2025 for its Blank Profile Grinding Machine BPG-15, highlighting its expertise in precision engineering. |

Advanced Engineering for Unmatched Precision

At its core, the BPG-15 incorporates a range of cutting-edge technologies designed to enhance precision and efficiency.

“The BPG-15 machine is a Precision 4+1 axes CNC cylindrical grinding machine that utilizes the pinch/peel method of grinding, ensuring superior performance and optimal concentricity,” Venkatesan detailed. “It features linear motor technology, offering high dynamic response, and a direct drive for the rotary axis (C-axis) for smooth and efficient operation.”

In addition to its advanced control system, the machine’s rigid base, constructed with a special dampening material, significantly reduces vibrations. “These advancements combine to deliver exceptional accuracy, concentricity, and surface roughness for carbide tool manufacturers,” Venkatesan stated.

Collaboration and Research: The Backbone of Innovation

WIDMA regularly collaborates with academia, industry bodies, and R&D institutions to develop next-gen solutions like the BPG-15.

“We leverage some leading engineering institutes to incorporate design enhancements and technological advancements in our offerings,” Venkatesan noted. “We have a long-standing association with IMTMA for various trainings on skill development, which strengthens our team’s competence in building what’s next.”

Furthermore, the company ensures that every product is rigorously tested before deployment. “We also leverage the capabilities of external agencies such as the Advanced Machine Tool Testing Facility (AMTTF) to ensure a robust and fail-safe machine testing mechanism,” he added.

The company’s strong R&D process has positioned it as a recognized innovator, continuously addressing complex manufacturing challenges while staying ahead of emerging trends like high-speed machining, sustainability, e-mobility, and exotic materials.

|

NITYASREE |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe