COMMITTED TO PRECISION

Sunita Engineering Corporation has long been recognized in the CNC micro-milling sector for its continuous innovation and drive to manufacture with precision. The company recently added the IMTMA Best Design Award, presented by Indian Machine Tool Manufacturers’ Association, for the 5-axis CNC Micro-Milling Machine 5X-100 to its long list of accolades.

“Winning the IMTMA Best Design Award for our 5-axis CNC micro machining center, the 5X-100, is a proud moment for Sunita Engineering Corporation. It validates our commitment to innovation, precision, and advanced manufacturing,” notes Rohan Kelkar, Head - Business Development, Sunita Engineering Corporation.

Further speaking on the merits of receiving the prestigious award, he states, “This recognition strengthens our credibility, boosts customer confidence, and motivates us to push the boundaries of CNC technology. It is a testament to the hard work of our team and our dedication to delivering world-class 5 axis micro machining centers.”

The Inspiration Behind the 5X-100

According to Kelkar, the development of the award-winning 5X-100 was a natural evolution from the company’s experience in manufacturing 3-axis and 4-axis CNC micro-milling machines. Customers in precision-driven industries demanded a compact 5-axis solution, especially for intricate parts. The Jewelry sector also drew attention to the need for efficient dust extraction to minimize material loss when machining gold.

Additionally, standard fixturing solutions were unsuitable for the extremely small parts that customers manufactured for industries such as Watchmaking and Medical Implants. As a swift response, the company developed custom fixtures to increase precision in machining. “Overcoming these challenges helped us create a highly precise, efficient, and application-focused 5-axis micro machining center,” he states.

What Makes the 5X-100 Stand Out?

Shedding light on the unique selling points of the 5X-100, he explains, “The 5X-100 stands out with its patented design that creates an isolated machining chamber, ensuring efficient dust extraction and protecting critical electro-mechanical components.”

The machine’s proprietary CNC controller improves motion dynamics for superior accuracy and surface finish. Equipped with a 4kW, 40,000 RPM spindle, the machine can support ultra-small tools, as small as 0.1mm in diameter, enabling intricate and precise machining. “These features make the 5X-100 a world-class contender in 5-axis micro machining, ideal for industries demanding extreme precision and reliability,” Kelkar adds.

The Power of 5-Axis Machining

|

|

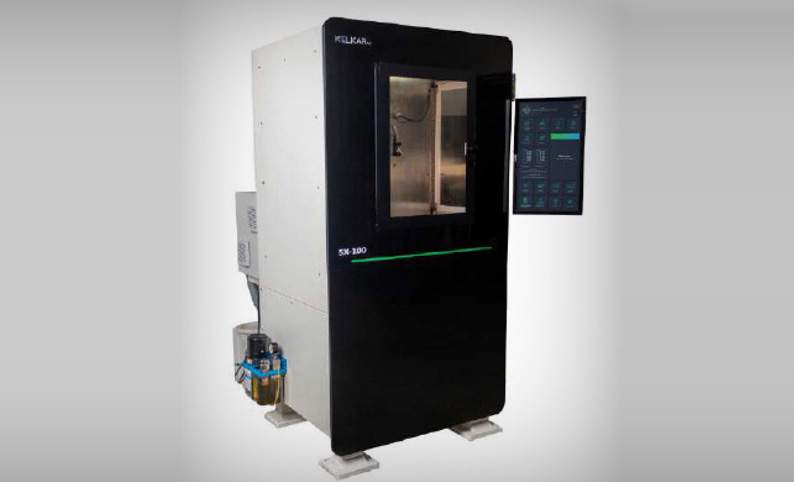

Sunita Engineering Corporation’s 5-Axis CNC Micro Milling Machine 5X-100. |

When considering conventional milling, which often requires multiple setups, the machine’s 5-axis capability allows complex geometries to be machined in a single setup. This advantage supports multi-angle cutting, improves precision, and reduces tool wear.

“This flexibility is crucial for intricate micro-milling applications, where maintaining tolerances at the micron level is essential,” he explains. “The ability to machine undercuts and complex curves with fewer setups improves efficiency and consistency.”

A machine with profound advantages as the 5X-100, inevitably becomes appealing for industries requiring high-precision components, such as Aerospace, Medical, and Jewelry Manufacturing.

An Industry Benefit

The 5X-100 is ideal for industries requiring extreme precision and intricate machining. Primary applications include micro-milling for aerospace components, medical implants, watchmaking, high-end jewelry, and precision engineering.

Its ability to handle ultra-small tools and achieve micron-level accuracy makes it perfect for manufacturing miniature parts, complex geometries, and high-quality surface finishes. “Industries like Electronics, Dental, and Mold-Making also benefit from its 5-axis capability, which enables efficient, high-precision machining with minimal setups,” shares Kelkar.

| Sunita Engineering Corporation’s 5X-100 CNC micro-milling machine recently won the IMTMA Best Design Award. The cost-effective 5-axis solution delivers micron-level accuracy, advanced dust extraction, and superior motion dynamics, making it a vital stepping stone in the Indian manufacturing industry. |

Transforming the Indian Market

With precision rearing its head as a constant theme, the company’s 5X-100 offers all the advanced capabilities of high-precision that are comparable to international micro-milling machines but at a significantly lower cost.

“Since we own the patented design, manufacture our own CNC controller, and produce all mechanical components in-house, we optimize costs to suit the Indian market,” he explains. “Our local manufacturing ensures quick technical support, minimizing downtime—an issue faced with imported machines that lack service centers in India,” he adds on a final note. This combination of world-class performance, affordability, and reliable support makes the 5X-100 a definite choice for manufacturers in India.

|

NITYASREE |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe