INDIA’S JOURNEY TO NEW FRONTIERS

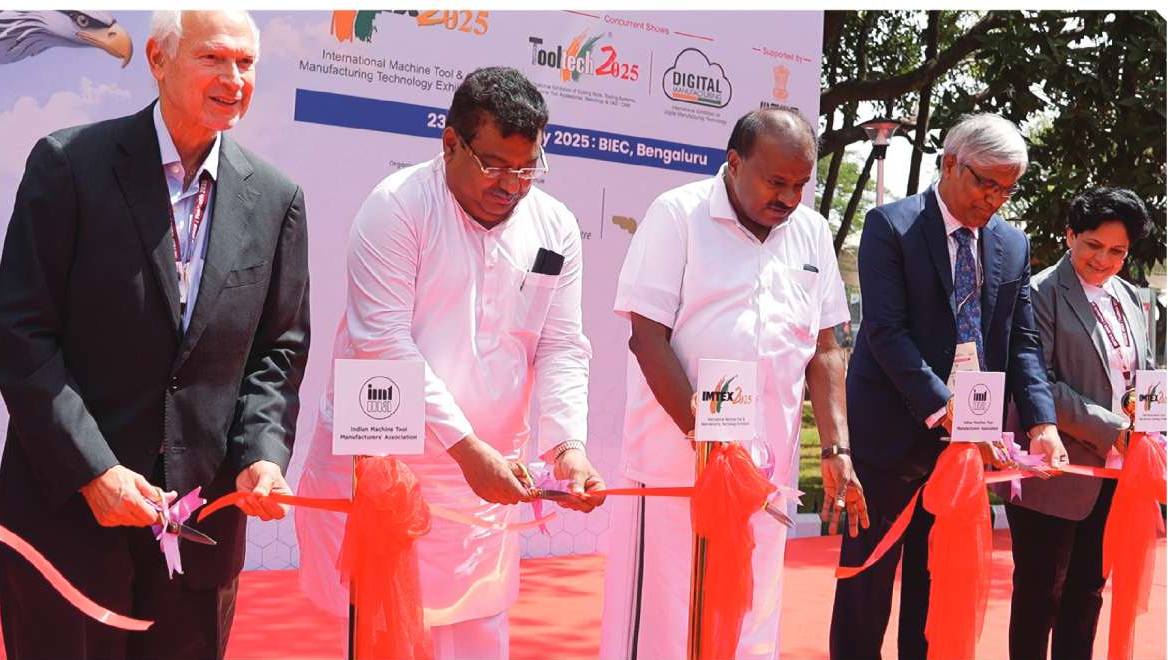

The curtains have drawn on what can be described as one of the most transformative and successful IMTEX ever. Organized by Indian Machine Tool Manufacturers’ Association (IMTMA), the last edition of the machine tool and manufacturing technology show, IMTEX 2025 & Tooltech 2025, did not just meet expectations—it shattered them, welcoming a staggering number of business visitors, surpassing its own earlier attendance record.

Organized by IMTMA, IMTEX 2025 was concurrently held with Tooltech 2025 and Digital Manufacturing 2025. The event, in its 22nd edition, attracted 1,100 exhibitors from 70 countries, drawing an astonishing 1,33,166 business visitors. Reaffirming its stature as South Asia’s premier machine tool and manufacturing tech exhibition, it marked a new milestone in the world of manufacturing innovation.

The expansive venue Bangalore International Exhibition Centre (BIEC), Bengaluru, spanning 90,000 sq mt area across 8 halls, surpassed the scale of previous editions. As Ramesh T K, Managing Director, Ace Designers Ltd, AceMicromatic Group, put it, “All IMTEXs are interesting, but what made this one special and better was that it had the largest number of exhibitors, the largest number of halls, and, of course, the largest number of visitors.”

|

| Fondly remembered as the ‘Guru’ of the Machine Tool sector, Late Mr Shailesh R Sheth’s legacy was commemorated through a special program. |

Concluding on January 29, 2025, this seven-day tech showcase and knowledge exchange extravaganza is set to give the country a much-needed edge. It marked the closing of a chapter in India’s most confident stride toward becoming a global powerhouse, featuring groundbreaking innovations aligned with the nation’s vision of self-reliance and sustainability.

Amidst the innovations and advancements shaping India's manufacturing landscape, IMTMA took the opportunity to honor one of the industry’s guiding lights—Late Mr Shailesh R Sheth. Fondly remembered as the ‘Guru’ of the Machine Tool sector, his legacy was commemorated through a special remembrance program, underscoring his enduring influence on the industry. The event featured a heartfelt memorial lecture delivered by Jamshyd N Godrej.

An eminent independent corporate advisor and a Board Member at Bharat Fritz Werner Ltd, Late Mr Sheth’s multifaceted contribution to the growth of IMTMA and the Indian Manufacturing Industry remains unparalleled. At the august gathering at IMTEX 2025, attendees recollected his impactful efforts toward promoting the Indian Machine Tool industry. The event commenced with a documentary film, followed by his associates from IMTMA narrating their shared experiences with him.

| IMTEX 2025 attracted 1,100 exhibitors from 70 countries, drawing an astonishing 1,33,166 business visitors, marking it as the largest edition ever, held across 90,000 sq mt at BIEC, Bengaluru. |

From Showcase to Impact

|

| International Seminar on Machining Technologies (ISMT) 2025 highlighted evolving trends in machining technologies. |

From CNCs and robotics to additive manufacturing and AI-led systems, IMTEX 2025 was a full-spectrum showcase of the next phase of industrial evolution. However, it wasn’t just about product features—it was about purpose, processes, and problem-solving. IMTEX 2025 saw a marked shift in conversations. “Visitors meant business, and there couldn’t be a better time to engage in machine tools,” points out Jibak Dasgupta, Director General & CEO, IMTMA & BIEC. “This time, the machines at the event rivalled what you’d see at IMTS – The International Manufacturing Technology Show (North America), EMO Hannover, or JIMTOF (Japan International Machine Tool Fair), indicating that IMTEX has actually come a long way.”

Ravi Raghavan, Managing Director, Bharat Fritz Werner Ltd and Immediate Past President, IMTMA, shared, “We’ve probably broken all records for footfall, but what’s remarkable this time is the quality of engagement. Visitors spent serious time exploring the machines and having deep technical discussions. That’s a real game-changer.”

The focus had clearly shifted from products to purpose and this tone resonated across the halls. Left impressed and lauding the quality of the visiting crowd, Soundhar Rajhan K, Chief Strategy Officer, LMW Ltd, highlighted the industry’s shift toward customized machining solutions, stressing that no more commodity machines can sell; only solutions can sell. “Customers no longer come for basic equipment; they seek the company’s expertise in curating customized solutions, from machine recommendations to tooling advice.”

Automation & Digitization in Overdrive

|

| Auto Components Industry Transformation Summit, jointly hosted by the ACMA (Automotive Component Manufacturers Association of India) Mobility Foundation and IMTMA, brought together top minds to reimagine the future of auto components manufacturing. |

If one theme tied together all halls of IMTEX 2025, it was automation. Ramadas P, Managing Director, AceMicromatic Group–a veteran of the machine tools industry, noted, “Automation has become the need of the hour. Whether you like it or not, automation is here to stay.” He further emphasized the rising demand for robotic and cantilever solutions across MSMEs and larger enterprises alike.

Niranjan Nayak, Managing Director, Delta Electronics India Pvt Ltd, a key player in power and thermal management solution, exclaimed, “This is a very important show for us!” The company made its presence felt at IMTEX 2025 by urging its machine tool partners to align solutions with global trends like automation and digitization and also launching its CNC controller, the high-performance next-gen five NC series.

“Today, the industry is going through a transformation,” Siva Arvinth, President - Machine Tool Division, LMW Ltd, added, “Customers expect faster and better performance, increase of productivity, and reduction of cycle time, amidst the shortage of skilled labor availability.”

|

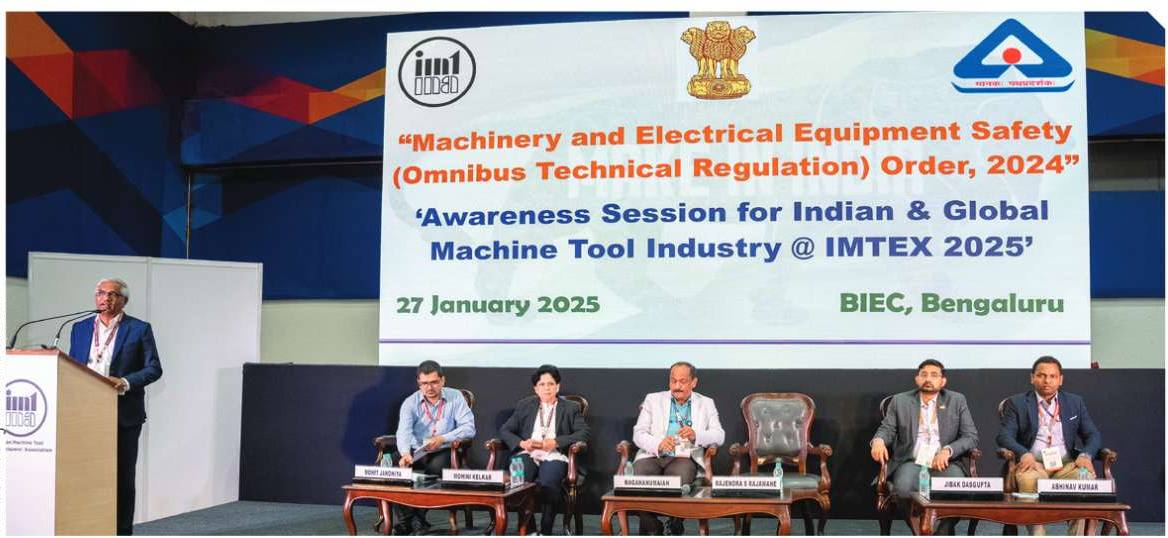

| Under the aegis of the Ministry of Heavy Industries (MHI), IMTMA also organized an awareness session on Omnibus Technical Regulations (OTR) at IMTEX 2025. |

Delta’s SCARA Robot integration into LMW’s SmartTurn machine marks their strategic alliance. “So now this IoT, industrial automation and the solutions, what Delta and other companies are doing will really enhance the performance of the machine, giving a value experience to the customers,” asserted Arvinth.

Blaser Swisslube also highlighted its digitalized and automated support tools, which integrate seamlessly with the Industrial Internet of Things (IIoT), ensuring the highest productivity and competitiveness.

|

AceMicromatic Group and German Engineering Federation (VDMA) at IMTEX 2025 hosted an exclusive open show for German, European, and American delegates, showcasing India’s advancements. |

Global-Local Synergy & Industry Transformation

|

| KLS Gogte Institute of Technology, Belagavi, clinched the top spot in the Manufacturing Technology Quiz Contest. |

What was once a show largely dependent on international technologies now echoed the voice of a confident India designing for India—and beyond. In a special initiative, AceMicromatic Group and German Engineering Federation (VDMA) hosted an exclusive open show for German delegates and a few European and American delegates, offering a closer look at India’s manufacturing prowess and highlighting the innovations on display.

The foreign delegates appreciation of the technology and solutions highlighted India’s evolution from an emerging market to a global manufacturing hub. Commenting on it, Ramesh TK, Managing Director, Ace Designers Ltd, said, “We are heading towards an era of joint manufacturing, and the importance of India is growing—not just for making in India, but for making for the world.”

Underscoring the company’s collaboration with BFW for advancing sophisticated machining solutions and the commitment to expanding its Indian presence, Victor Backman, Chief Executive Officer, SMT Swedish Machine Tool AB, remarked, “How impressive the Indian market is,” clearly moved by the response from customers and partners.

Takashi Yamazaki, President, Yamazaki Mazak Corporation, accentuated the company’s long-standing relationship with the Indian market. Reflecting on the shift in demand, he highlighted the rising need for both commodity and high-end machines in industries like Aerospace, Semiconductors, and Railways.

|

The i2 Academia Pavilion saw participation from 33 colleges, with KLS Gogte Institute of Technology, winning the first prize, followed by Amrita Vishwa Vidyapeetham, and SASTRA Deemed to be University. |

Sustainability & Future-Ready Ecosystems

|

| Chennai Institute of Technology bagged the second prize in the Quiz Competition. |

Beyond performance, energy efficiency and sustainability were hot topics. Automation providers weren’t just pitching ROI, but also carbon savings. At the forefront of change, Yatendra Kumar (Rajput), Business Head, MotulTech India Pvt Ltd, highlighted the company’s groundbreaking biosourced lubricant MOTUL GREEN TECH™ range, which made its Indian debut at IMTEX. “The footfall has been fabulous this year,” Kumar noted, “and what’s truly encouraging is the serious interest in sustainable development.”

With the stage set as such, praising IMTEX for its scale and energy, Yamazaki Mazak President, on transition from traditional automotive manufacturing to EVs, said, “Mazak is prepared for the shift with advanced machine tools tailored for EV components.” He further shed light on the company’s role in the energy sector, where their versatile technologies, such as laser cutting machines, meet the needs of solar and wind energy manufacturers.

In terms of future-ready solutions, digitalization has moved from being a buzzword to being a business need. Dr Vishwas Puttige, Business Head, amace solutions—part of AceMicromatic Group, promoting accessible additive manufacturing (AM), was equally impressed with the number of inquisitive guests flocking to their booth. Adding another feather to its hat, amace solutions partnered with National Centre for Additive Manufacturing (NCAM) to drive innovation in metal additive manufacturing during IMTEX 2025. It was evident that such partnerships further bolster India’s readiness for Industry 4.0 and fulfilling the Sustainable Development Goal (SDG).

With a Holistic Approach

Taking it further, a highlight of IMTEX 2025 was the strong emphasis on talent development. The i2 Academia Pavilion was abuzz with activity. The flagship initiative of IMTMA aims to promote collaboration between industries and academia, develop transformative new technologies, and understand each other’s contexts and challenges through the platform of IMTEX.

In a momentous celebration at IMTEX 2025, the i2 Academia Pavilion witnessed the acknowledgment of outstanding students. Among 33 colleges and more than 50 projects, two prestigious awards were presented. The first prize, in the i2 Academia Pavilion Award category, worth INR 50,000, was awarded to KLS Gogte Institute of Technology, Belagavi. The second prize, worth INR 25,000, was secured by Amrita Vishwa Vidyapeetham, Kollam. The third prize, worth INR 15,000, was won by SASTRA Deemed to be University, Thanjavur.

|

| The i2 Academia Pavilion at IMTEX 2025 where students from engineering colleges displayed their innovative engineering projects. |

In addition to these awards, the Popular Choice Award was also presented. The first prize in this category was won by Vishwakarma Institute of Technology, Pune, while SASTRA Deemed to be University, Thanjavur, secured the second prize.

The Manufacturing Technology Quiz Contest was also hosted. The event brought together ten engineering colleges, with KLS Gogte Institute of Technology, Belagavi, clinching the top spot and Chennai Institute of Technology finishing second.

Rajendra Rajamane, President, IMTMA, underscored the significance of such competitions, stating, “The manufacturing industry continues to suffer from skilled worker shortages due to increasing youth interest in white-collar jobs, making these events even more crucial.”

JAGRUTI, an IMTMA initiative, was also held. Designed to nurture students and make them industry-ready, the program focused on honing their abilities to observe and quantify those observations effectively. To instill these critical skills, the 29 participating students were divided into smaller groups and were asked to present their observations. Mentors provided feedback, highlighted missing aspects, and guided the students on how to improve their analytical approach.

IMTMA also organized an awareness session, under the aegis of the Ministry of Heavy Industries (MHI), on Omnibus Technical Regulations (OTR) at IMTEX 2025. The OTR for Machinery and Electrical Equipment Safety-2024 is a pioneering framework in India, aimed at enhancing the Manufacturing sector capabilities and ensuring safer workplaces. It was notified on August 28, 2024, and will come into effect on August 28, 2025. Dr Nagahanumaiah, Director, Central Manufacturing Technology Institute (CMTI), delivered a special address on OTR. Mohit Janohiya, Scientist ‘D’ and Joint Director, Central Marks Department – I, Bureau of Indian Standards (GoI), gave a detailed presentation on the subject.

With the aim to facilitate export opportunities for Indian machine tool manufacturers and foster global partnerships, IMTMA, along with EEPC India, organized the ‘Engagement with Overseas Buyers’. The two-day event received an overwhelming response from the machine tool importers from the countries including Russia, Sri Lanka, UAE, and Vietnam.

During IMTEX 2025, a seminar and live webinar on ‘Export Controls for Japanese Machine Tools’ conducted by Japan Machine Tool Builders’ Association (JMTBA) at the IMTMA Technology Centre. The seminar provided the participants with an overview of security export regulations and compliance requirements for Japanese machine tools. Designed exclusively for distributors of Japanese machine tools in India, the event emphasized the role of export controls in preventing the misuse of sensitive technologies.

| IMTMA and EEPC India organized the ‘Engagement with Overseas Buyers’ connecting global buyers from countries like Russia, Sri Lanka, UAE, and Vietnam, fostering global trade opportunities. |

|

| Engagement with Overseas Buyers’ provided IMTEX exhibitors a significant opportunity to penetrate the overseas markets. |

Strategic Collabs & Deal Flows

Quantifying strategic networking impact, Saurabh Kaul, Commercial Director, Quaker Houghton, emphasized, “We’ve been part of IMTEX for years, but this time, the quality of footfall and new initiatives like the ACMA-IMTMA Summit, industry-specific seminars and fireside chats, have fostered real collaboration.”

The ‘Auto Components Industry Transformation Summit’, jointly hosted by the ACMA (Automotive Component Manufacturers Association of India) Mobility Foundation and IMTMA, brought together top minds to reimagine the future of auto components manufacturing.

Similarly IMTMA’s flagship event, International Seminar on Machining Technologies (ISMT) 2025, was dedicated to bringing the global manufacturing community together while highlighting evolving trends in machining technologies, through keynotes, technical sessions, and panel discussions.

Innovation, the Great Equalizer

|

| The ‘Jagruti - IMTMA Youth Programme’ aims to help engineering students stay abreast of the latest trends in the Manufacturing sector. |

IMTEX 2025 had ‘innovation’ as its main focus through the prestigious IMTMA Best Design Award 2025 that honored indigenous design excellence and development. The winners this year were: Grind Master Machines Pvt Ltd – Special Purpose Bearing Race Superfinishing Machine; Kennametal India Ltd – Blank Profile Grinding Machine BPG15; and Sunita Engineering Corporation – 5 Axis CNC Micro Milling Machine 5X-100. Apart from innovation, global competitiveness also was in the limelight. The IMTMA Export Performance Award, in memory of Shailesh R. Sheth, recognizes companies that have made outstanding contributions to India’s machine tool exports. The honorees included Pragati Automation Pvt Ltd and Indotech Industries India Pvt Ltd.

Alongside, the IMTMA - Cooper Award for Outstanding Supply Chain Unit in Memory of Sir D.B. Cooper was conferred upon Sphoorti Machine Tools for the year 2025 and Vikram Salunke of Accurate Group was honored with the IMTMA - Premier Outstanding Entrepreneur Award in Memory of Vinod Doshi.

|

| JMTBA Seminar on ‘Export Control for Japanese Machine Tools’. |

Taking this forward, at their ‘Town of Technology’ themed stall encapsulating the company's commitment to advanced manufacturing, Parakramsinh G Jadeja, Chairman & Managing Director, Jyoti CNC Automation Ltd, declared India’s arrival as an innovation leader. “The Indian market has truly awakened,” he commented with evident pride. “Our manufacturing processes have matured significantly. We are no longer just comparing ourselves to Japanese and German standards; we are poised to set new benchmarks for them to follow.”

Similarly, capping the event’s transformative impact, Christian Müller, Member of the Board and CSO, GROB-WERKE GmbH & Co. KG, declared, “We are an Indian company with German DNA,” emphasizing the company’s commitment to producing cutting-edge machines locally while maintaining world-class standards. With GROB’s key highlight, the G350 5-axis universal machining center, powered by flipping technology, is a perfect fit for global shops looking for a sustainability revolution.

Reinforcing India’s strategic role in global manufacturing, Andreas Vollmer, Sales Director, Member of the Executive Board, Paul Horn GmbH—the company represented by NN Combined Engineering Agencies Pvt Ltd—noted that ‘India is a fast-evolving, challenging market’. Paul Horn has steadily built its footprint through its collaboration with NN Combined Engineering Agencies Pvt Ltd, which is following a focused, exclusive partnership strategy rather than spreading thin across multiple distributors.

|

The Export Performance Award, in memory of Shailesh R. Sheth, was awarded to Pragati Automation Pvt Ltd and Indotech Industries India Pvt Ltd, acknowledging their contributions to India’s machine tool exports. |

All in all, the successfully concluded IMTEX 2025 furthers India’s push in the Manufacturing sector, which focuses on diversifying into upgrading production lines and industrial capacity, alongside the creation of a global competency-based domestic supply chain network. As the stakeholders and fraternity eagerly look forward to the upcoming edition, achieving the sector’s true potential and raising the sector-wise contribution of manufacturing to the country’s GDP is near reality.

|

Sovan Tudu |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe