Revolutionizing Automated Machining

Global technology and innovation leader in measuring and testing technology, Blum-Novotest GmbH, chose a GROB G150 universal machine with a GROB GRC-R60 robot cell and GROB control software for its significant automation and operational benefits.

Founded in 1968 and headquartered in Ravensburg, Germany, Blum-Novotest GmbH is one of the world’s leading manufacturers of high-quality measuring and testing technology for the international Machine Tool, Automotive, and Aerospace industries as well as many other demanding industrial sectors all over the world.

Today, the family-owned company employs over 650 employees in 18 locations across Europe, America, and Asia.

Blum-Novotest GmbH is a global technology and innovation leader in measuring and testing technology which develops and manufactures solutions for its customers that meet the highest quality standards.

|

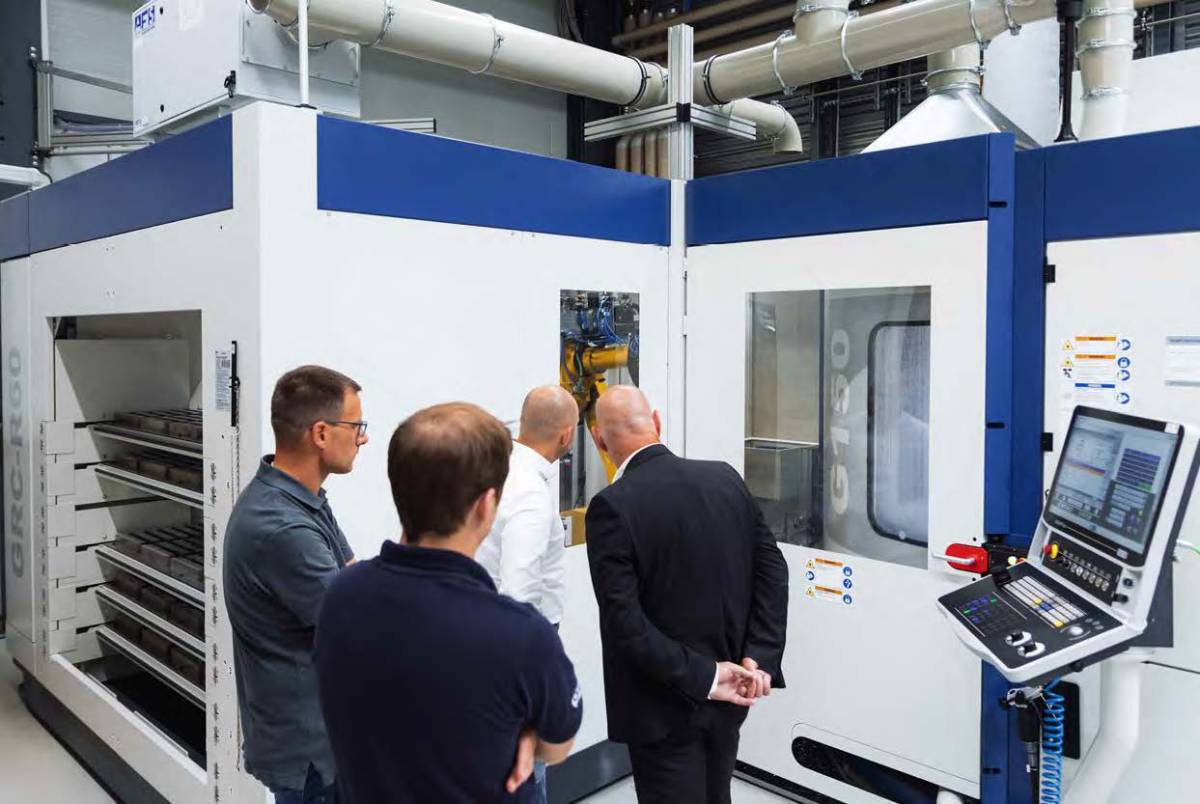

The square blanks are produced in the GROB plant. In the picture are seen Marcel Kühnle from Blum-Novotest, Ralph Birkle, Patrick Müller and Joachim Stock from GROB. |

It quickly became clear to GROB that Blum-Novotest’s commitment to quality was genuine. Thus, the first contact between the two companies was about acquiring a new machine for the production of system carriers for two different series (NT carriers for LaserControl Micro Compact NT and LC carriers for LC-DIGILOG). The criteria were that production should be highly efficient and cost-effective and have an autonomy of at least 24 hours.

“Our contacts at Blum were well prepared right from the start,” recalls Joachim Stock, Area Sales Manager, GROB. “They gave us a clear task, a short, concise specification sheet, which we used not only to create a specification for the machine but also to develop a concept for further discussions.”

So it was not surprising that only three weeks passed from the first inquiry to the first offer.

|

The GROB G150 with GRC-R60 automation reduced operational steps from four to two, achieving up to 50% time saving while enabling the production of 11 part types with a single clamping setup. |

Knowing GROB-WERKE

For over 95 years, GROB has been active as a globally operating family-owned company in the development and manufacture of equipment and machine tools. Customers include the most renowned automotive manufacturers, their suppliers, and companies from a wide range of industries.

With production plants in Mindelheim (Germany), Bluffton, Ohio (USA), São Paulo (Brazil), Dalian (China), Pianezza (Italy) and Bangalore (India), as well as worldwide service and sales subsidiaries, GROB is internationally positioned.

The portfolio ranges from universal machining centers and highly complex manufacturing systems with their own automation to manual assembly stations and fully automated assembly lines.

Furthermore, production systems for electric motors and assembly systems for battery and fuel cell technology are part of the product range. In-house solutions are implemented for the coating technology of engine components, the machining of turbine housings, and the processing of structural and chassis components. With the GROB-NET4Industry software developed for the digitization and networking of production processes, GROB is taking big steps into the digital future.

Deep Hole Drilling

The workpiece to be machined, a square blank, is then manufactured into two system carriers (LaserControl Micro Compact NT and LC-DIGILOG).

They have a length of 150 to 300 mm and have a cable duct hole almost throughout. “Since the part has to be drilled 270 mm deep on one side, a corresponding tool length is required, which relatively many competitors were unable to meet for this machine size,“ explains Marcel Kühnle, Deputy Production Manager, Blum- Novotest GmbH. “Larger machines with corresponding traverse paths do exist on the market, but they are insanely large and thus are not really suitable for our components.”

The original idea of purchasing a bar-loading turning-milling machine was also quickly rejected for cost reasons. GROB was included in the bidding process because its machine met the specifications, component requirements, and drawings, especially with its ability to handle tool lengths of up to 385 mm.

|

Blum-Novotest’s collaboration with GROB integrated ultrasonic cleaning and flexible automation, allowing mixed-size production and delivering a state-of-the-art system tailored for 24-hour autonomous, cost-effective, and efficient machining. |

Turnkey Solution Brings Breakthrough

In further discussions, it quickly became clear that a machine with automation would offer the ideal technology for Blum‘s requirements. An idea that was then anchored in the specifications, combined with the requirement for autonomy of at least 24 hours. On the basis of these specifications, further information, and after exchanging various CAM data, a feasibility study was prepared at GROB, which included cycle times as well as initial proposals for special tools and clamping devices.

After two weeks, the first meeting took place in Mindelheim, where a G150 with a GRC-R60 robot cell was presented at the GROB Technology and Application Center (TAC) on the subject of ‘Demonstration of an Aluminum Component’. The Blum technicians were surprised to see that the demo component matched their defined acceptance component. “After this visit, it was finally clear to us that a machine with the process was the best solution for our purposes,” shares Kühnle. “The arguments of this turnkey solution with automation presented by GROB were too convincing for us.”

Cost Savings through Reduction of Work Steps

One of the most important arguments for Blum-Novotest GmbH was the intelligent GROB4Automation control software, with which the individual operation steps could be significantly reduced. Where previously four operations per part were necessary, GROB managed it for all eleven different types with two operations and one clamping. Thus, in OP10, five sides of the blank were to be machined and deephole drilled, and in OP20, the sixth side was to be machined. This was achieved by standardizing the blank cross-section, resulting in a jaw design in the fixture that allowed all eleven types to be clamped in the same way. A procedure that achieved a potential time saving of up to 50 percent compared to the original method, and also significantly reduced non-productive time. GROB automation also made it possible to map the variance of both the smaller and larger part spectrum on one machine. In the past, the smaller and the larger parts spectrum had to be produced on two different machines.

Another advantage of GROB’s GROB4Automation control software in this application is its enormous flexibility, as it does not have to be run by type, but can be loaded mixed with other sizes of a component and individual parts can also be produced without any problems. When an order is created, among other things the blank size is defined and specified.

Ultimately, GROB’s own control software is at the heart of the automation cell to ensure the required flexibility. However, the key to the successful implementation of this customized application was not only GROB’s intelligent control software, but also the exemplary cooperation between Sales, Application Engineering, and Project Planning at GROB, as well as the close and intensive exchange with Blum-

Novotest GmbH.

| Automation perfectly matched to its own needs, the possibility of deep hole drilling up to 280 mm, and an intelligent control system were the winning arguments for the measuring equipment manufacturer Blum-Novotest GmbH to choose a GROB G150 universal machine with a GROB GRC-R60 robot cell and GROB control software. |

Special Equipment Ultrasonic Cleaning

Thanks to the flexibility of the GROB GRC-R60 robotic cell, the layout of the plant could be adapted to the conditions and ultrasonic cleaning could be integrated at the customer‘s request. This adaptability enabled Blum-Novotest to receive a state-of-the-art system tailored perfectly to its needs.

|

Poonam Pednekar |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe