The SensAIbox

SensAIbox is an innovative AI-driven solution that fills a gap in the market by combining hardware and software into a cohesive system. It not only reduces waste but also generates Environmental, Social, and Governance (ESG) reports and addresses the critical issue of sustainability and waste management across industries.

Industries such as machine tool, precision engineering, smart building management, and agriculture face significant challenges in managing waste effectively, tracking resource utilization, and meeting sustainability goals. These sectors are often hindered by inefficiencies that lead to environmental and financial costs. SensAIbox, an innovative new product, integrates artificial intelligence (AI), advanced sensors, and machine learning (ML) to offer real-time insights and actionable recommendations for waste reduction.

Its features include monitoring tool conditions, tracking power consumption, and analyzing environmental data to improve operations.

By providing immediate feedback to operators, it empowers users to enhance productivity and minimize downtime. Additionally, its robust data security measures and wireless connectivity ensure seamless and secure deployment across various industries.

This innovative device fills a gap in the market by combining hardware and software into a cohesive system that not only reduces waste but also generates Environmental, Social, and Governance (ESG) reports. By targeting high-impact industries, SensAIbox contributes to sustainability while providing businesses with measurable improvements in operational efficiency and cost savings, positioning itself as a vital tool for the future of sustainable industry practices.

|

Tech Talks is a column by industry veteran and journalist Reji Varghese that talks about the latest advancements in Machine Tools, provides snippets from history, interesting facts, etc. about the Machine Tool industry. |

SensAIbox integrates physics and predictive AI to optimize CNC machining by combining the precision of physical modeling with the adaptability of artificial intelligence. Leveraging AI physics principles, it uses ML to simulate and predict machining dynamics, such as tool wear, vibration, and thermal effects, ensuring real-time process optimization.

Physics-inspired algorithms model interactions between materials and cutting tools, enabling SensAIbox to adaptively adjust machining parameters for enhanced precision, efficiency, and reduced waste. This fusion not only accelerates decision-making but also aligns CNC operations with physical laws, delivering innovations in manufacturing quality and productivity.

The Founders

SensAIbox was developed by Marcus Taylor and Brian Tan. Taylor specializes in scaling businesses, innovation, and disruptive technologies across industries like IoT, Agritech, AI and Big Data. He has previously launched successful ventures like Planet Computers Ltd and Silent Sensors Ltd, raised substantial grants, and transformed Erlang Solutions Ltd into a multi-million-pound enterprise through strategic leadership and key partnerships.

Tan is an IT executive with over 38 years of expertise in digital transformation across Asia Pacific. With leadership experience at KPMG and multinational startups, he excels in leveraging technology for growth. A Computer Science graduate, Tan is passionate about guiding digital transformations.

SensAIBox for CNC Machines

SensAIbox offers several key components that can be fitted to any CNC machine, enhancing its capabilities for waste reduction, efficiency, and sustainability.

AI-Driven Waste Reduction System

- Advanced AI algorithms analyze real-time production data to identify and minimize waste in metal removal machining processes.

- Provides actionable recommendations for reducing material consumption and optimizing production parameters.

Instrumented Fixture Monitoring

- Monitors tool conditions to maximize utilization and minimize downtime.

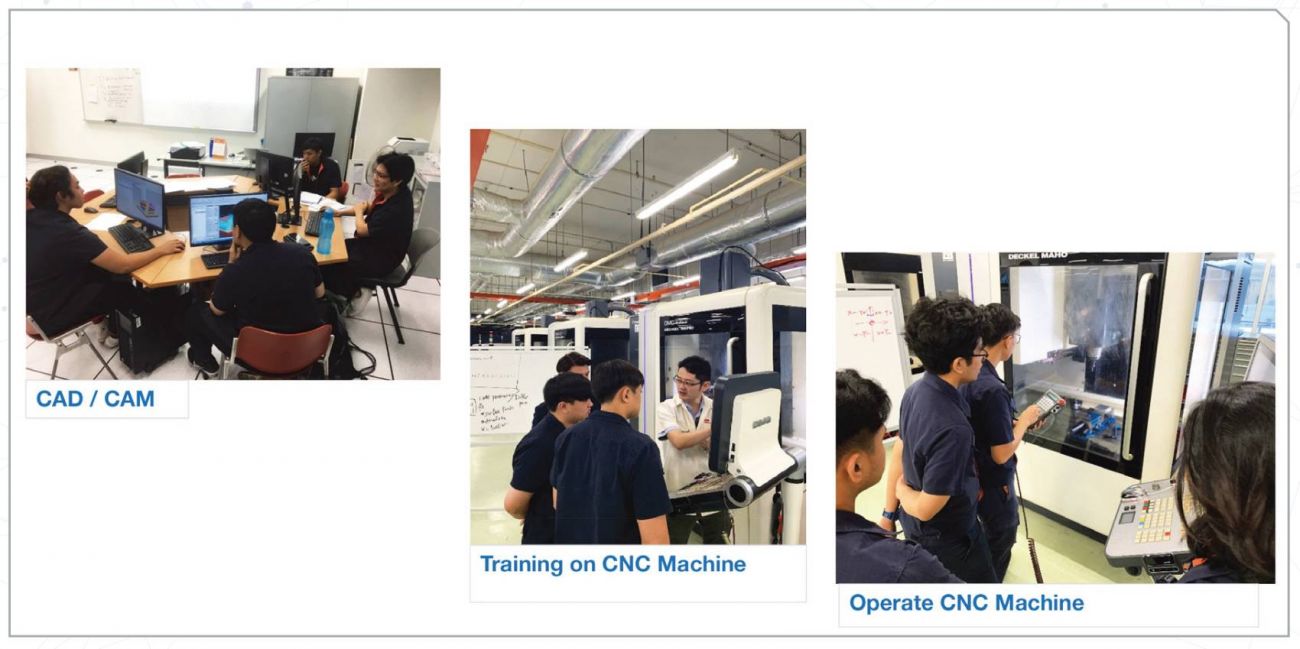

- Enables enhanced training for new operators and provides real-time feedback for experienced ones.

Marcus Taylor, Chief Executive Officer, SensAI, says, “SensAI represents a paradigm shift in

how industries approach sustainability. We are not just offering a product, we’re providing a solution that transforms waste into opportunity, turning environmental challenges into competitive advantages.”

Data Security

- Incorporates a robust crypto algorithm to ensure data integrity and privacy.

- Safeguards critical production and operational data.

Wireless Connectivity

- Supports Wi-Fi and 4G/5G/6G connectivity for seamless integration across various locations.

- Ensures uninterrupted monitoring and data collection.

Power Consumption and Carbon Monitoring

- Tracks power usage to facilitate carbon footprint monitoring.

- Addresses legal requirements and creates opportunities for sustainability metrics.

Machine Learning for Continuous Improvement

- Embedded machine learning algorithms adapt to the specific CNC machine's environment.

- Continuously refines algorithms to deliver increasingly effective waste reduction and sustainability strategies over time.

Operator Feedback System

- Provides instant feedback to operators through a display dashboard, an app, and a haptic feedback system on a wrist-worn device.

- Simulates fixture vibrations, enabling operators to react promptly to changing tool conditions and maintain optimal performance.

By integrating these components, SensAIbox transforms standard CNC machines into smart, efficient, and environmentally conscious production units, offering significant benefits in waste reduction, operational efficiency, and sustainability reporting.

SensAIbox is an innovative system designed to optimize CNC machining processes through real-time monitoring and AI-driven adjustments.

|

By providing immediate feedback to operators, SensAIbox empowers users to enhance productivity and minimize downtime. Additionally, its robust data security measures and wireless connectivity ensure seamless and secure deployment across various industries. |

System Operation

The system operates in several key stages:

Calibration and Data Collection

The process begins with the user creating calibration sets for a specific material. These sets involve making square cuts at various depths and speeds, collecting data on cutting parameters and resulting surface finishes. During this calibration, acoustic and vibration signals are captured using microphone and vibration sensors placed inside the CNC cabin and on the spindle, respectively. This data forms the AI training set, establishing baseline signals for ideal cutting conditions.

Real-Time Monitoring and Analysis

Once calibrated, SensAIbox continuously monitors the machining process in real time. The system compares current acoustic and vibration signals to the baseline data, detecting any significant deviations that might indicate issues with the cutting process. This constant comparison allows for immediate identification of anomalies in tool performance or cutting parameters.

Intelligent Adjustments and Optimization

The heart of SensAIbox is its advanced AI algorithm, the Entropy-Controlled Adaptive Chaos Fusion Model (ECA-CFM). This model performs several crucial functions:

- It calculates real-time entropy deviations from baseline data to detect anomalies.

- It identifies chaotic patterns and adjusts milling parameters to restore stability.

- It employs predictive maintenance to anticipate tool and machine failures.

- It continuously learns and adapts through a dynamic feedback loop.

When deviations are detected, SensAIbox can trigger alerts for tool inspection or dynamically adjust the G-code to optimize cutting parameters. This real-time optimization helps extend tool life, reduce material waste, and improve overall machining efficiency

Differences Between the SensAIbox and Generative AI

The key difference between SensAIbox's approach and generative AI lies in their focus and application. SensAIbox uses physics-based predictive AI to model, simulate, and optimize real-world processes like CNC machining by adhering to physical laws and real-time system dynamics.

Generative AI, on the other hand, focuses on creating new data or content, such as images, text, or designs, by learning patterns in existing data without necessarily incorporating physical constraints or real-world process modeling.

|

This innovative device fills a gap in the market by combining hardware and software into a cohesive system that not only reduces waste but also generates Environmental, Social, and Governance (ESG) reports. |

While predictive AI in SensAIbox ensures precision and operational efficiency, generative AI excels in creative tasks and innovation without the strict requirements of physical accuracy.

SensAIbox's approach differs from traditional IoT and AI implementations by CNC machine manufacturers in its integration of physics-based modeling with predictive AI for real-time optimization. While CNC manufacturers often use IoT for monitoring machine performance and AI for analyzing collected data to predict maintenance needs or optimize workflows, these systems primarily rely on historical and sensor data.

In contrast, SensAIbox combines this data with physics-inspired algorithms to simulate and predict machining dynamics, such as forces, vibrations, and thermal behaviors, enabling more precise control and optimization of machining parameters during operation. This deeper fusion of AI with physical laws goes beyond diagnostics and monitoring, actively enhancing machining performance in real-time.

Unique Features Of SensAIbox

- Physics-Driven Predictive AI: Combines real-time physical modeling with AI to optimize CNC machining parameters dynamically.

- Enhanced Precision and Efficiency: Adapts machining processes using simulations of forces, vibrations, and thermal dynamics.

- Real-Time Optimization: Continuously adjusts operations for reduced waste, improved accuracy, and better productivity.

- Beyond Monitoring: Moves beyond IoT-based diagnostics by actively enhancing performance rather than just tracking machine health.

- Interdisciplinary Innovation: Leverages AI physics to align manufacturing processes with fundamental physical laws.

- Versatility: Can integrate with existing CNC setups, offering immediate operational improvements without extensive modifications.

|

By targeting high-impact industries, SensAIbox contributes to sustainability while providing businesses with measurable improvements in operational efficiency and cost savings, positioning itself as a vital tool for the future of sustainable industry practices. |

Bryan Tan, Senior Vice President, Business Development, SensAI, says, “What sets SensAIbox apart is its ability to bridge the gap between sustainability goals and operational realities. We’re empowering businesses to make data-driven decisions that not only reduce waste but also enhance productivity and profitability.”

|

Reji Varghese President RV Forms & Gears fngreji@gmail.com |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe