Advanced CNC Drill Tap Centers

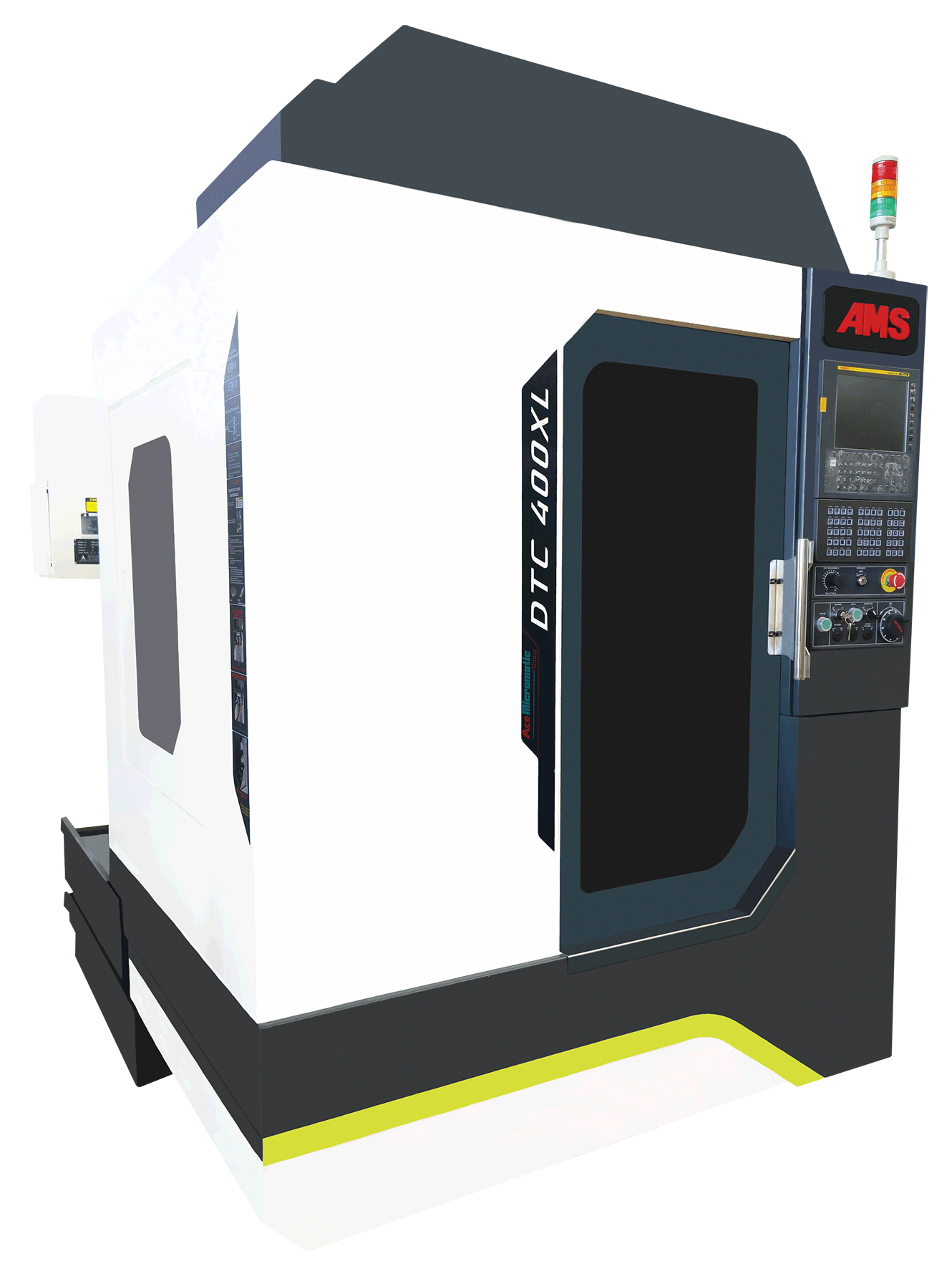

Revolutionizing Electronic Manufacturing with the DTC-400XL

In the dynamic world of electronic manufacturing, precision, speed, and reliability are critical to staying ahead of the competition. Enter the DTC-400XL CNC Drill Tap Center, a game-changer designed to transform manufacturing processes, ensuring unparalleled performance and efficiency.

Why AMS?

Ace Designers Ltd Machining Centre Division (MCD), under AMS brand, is one of the largest manufacturers of Machining Centers in India. Strong R&D facility, a passion to excel and a young dynamic team led by experienced professionals has fuelled the rise of AMS to this premier position. Offering one of the widest ranges (over 70 variants) of Machining Centers, both vertical and horizontal, AMS covers the entire gamut of milling applications, from the simple to the most complicated machines. AMS also offers turnkey options, automation, and tooled up solutions.

Precision and Efficiency at One’s Fingertips

Imagine a machine that guarantees the highest level of precision in drilling and tapping operations, drastically reducing cycle times and boosting productivity. The DTC-400XL does just that with its advanced technology. With spindle speed options ranging from 10,000 RPM to a blazing 24,000 RPM and rapid traverse rates of 60/60/48 m/min, machining processes become swift and accurate.

The company’s high-speed Drill Tap Centers, particularly the DTC-400XL, have been enhanced to meet the demanding standards of the electronic industry. Here’s what one gets with the DTC-400XL:

- High Rapid Rates: 60 m/min for X and Y axes, ensuring fast movement.

- Fastest Chip-to-Chip Time: Just 1.5 seconds, keeping your production line moving.

- Impressive Spindle Speed: Up to 24,000 RPM for top-notch drilling and tapping.

- High Acceleration: 1G acceleration for all axes, ensuring quick and precise movements.

- Ergonomic Design: Both functional and visually appealing, enhancing your workspace.

- Advanced Control: Equipped with Fanuc/Siemens/Mitsubishi controllers for seamless operation.

Tailored for Specific Needs

The DTC-400XL isn’t just another machine; it’s built to cater to the specific needs of the electronic manufacturing industry. Here’s how it can revolutionize operations:

- High-Speed Spindle: To achieve superior speeds in drilling and tapping, enhancing productivity.

- Robust Construction: The sturdy structure minimizes vibrations, ensuring consistent accuracy.

- User-Friendly Control System: The intuitive CNC control interface simplifies programming and operation.

- Automatic Tool Changer: The 16 /21 /24 Nos. - tool capacity allows for seamless transitions between operations.

- Precision Cooling System: The system helps maintain an optimal temperature for consistent performance, especially for spindles exceeding 20,000 RPM.

Versatility for Diverse Applications

Whether one is producing PCBs, mobile cases, or electronic enclosures, the DTC-400XL is their go-to machine. Its versatility shines in various applications:

- PCB Drilling and Tapping: Perfect for creating precise holes in printed circuit boards.

- Aluminum and Plastic Cases: Precision drilling and tapping for both metal and plastic mobile cases.

- High-Volume Production: Handles large-scale production runs with ease, ensuring high efficiency.

- Enclosure Manufacturing: Accurately drills and taps metal and plastic enclosures for electronic components.

- Connector Fabrication: Creates precise threads and holes for various electronic connectors.

Benefits that Can't Be Ignored

Integrating the DTC-400XL into operations offers numerous advantages:

- Boosted Productivity: Reduced downtime and increased throughput with high-speed operations.

- Consistent Quality: Precision engineering ensures high-quality results every time.

- Cost Efficiency: Accurate and reliable performance minimizes waste and rework.

- Easy Maintenance: Designed for straightforward access, ensuring long-term reliability and ease of upkeep.

Partner with a Leader in Innovation

Choosing the DTC-400XL means partnering with a leader in machining technology. ADL is dedicated to providing exceptional customer support and service, helping one maximize the benefits of their investment.

In an industry where precision, efficiency, and reliability are crucial, the DTC-400XL is poised to be a revolutionary addition to one’s manufacturing processes. From PCB drilling to high-volume production, this advanced CNC Drill Tap Center is engineered to meet and exceed one’s operational needs, driving innovation and excellence in electronic manufacturing.

Ace Designers Ltd – Machining Centre Division

Hall & Stall: 5/B-109

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe