Enhancing Material Productivity In Export Operations

Hero MotoCorp, a global leader in two-wheeler manufacturing, is constantly exploring avenues to strengthen its presence in the international market. With the growing demand for high-quality, cost-effective products, the company has adopted world-class manufacturing methodologies (WCM) to enhance material productivity, a cornerstone of its export operations. This article delves into the strategies and initiatives undertaken by Hero MotoCorp to achieve this goal, ensuring the seamless expansion of its global business.

The global market is dynamic and highly competitive. In the face of which, Hero MotoCorp faced challenges such as:

- Rising Material Costs significantly impacted profitability and pricing strategies.

- Inefficient Logistics led to high costs due to suboptimal container utilization.

- Maintaining Quality Consistency posed a challenge, as it involved meeting diverse international standards while minimizing defects.

- Additionally, Limited Collaboration with overseas partners resulted in delays and inefficiencies.

Solutions

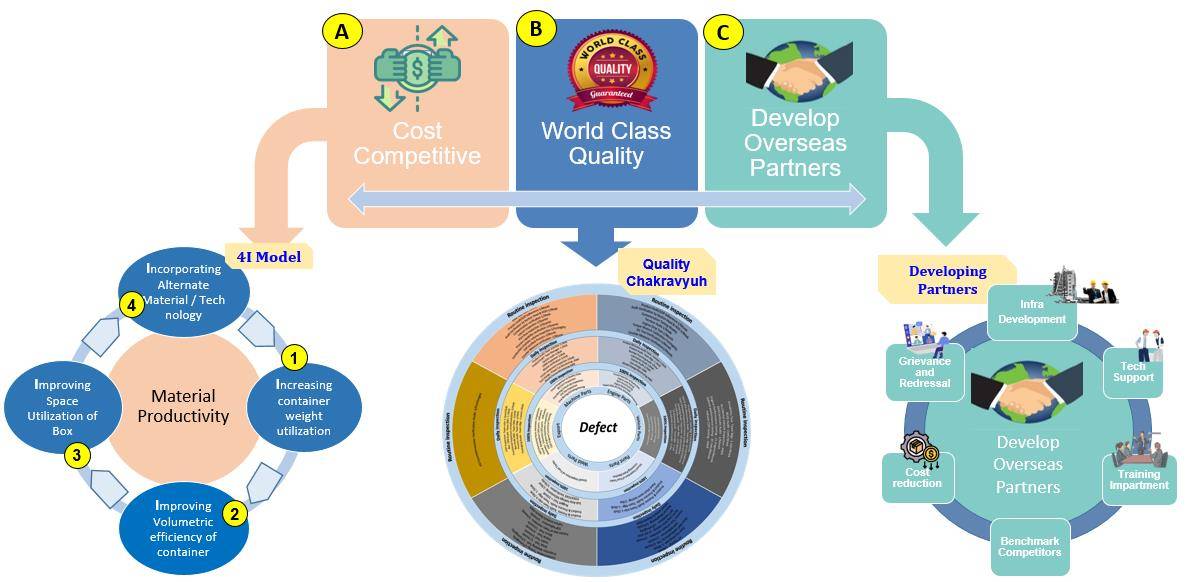

These hurdles required innovative solutions to not only sustain but also expand Hero MotoCorp’s global operations. To tackle these challenges, Hero MotoCorp implemented a three-pronged strategy:

Cost Competitiveness: Ensuring affordability through efficient resource management and advanced technology.

World-Class Quality: Adhering to international benchmarks for defect-free products.

Developing Overseas Partners: Building a robust global network for distribution and support.

For Cost-Competitiveness, Hero MotoCorp developed the 4i Model, a systematic approach aimed at optimizing resource utilization across its export operations. The 4i Model is a cyclic model which focuses on improvement in material productivity.

Increasing Container Weight Utilization:

Hero MotoCorp focused on maximizing load capacity to reduce transportation costs by adopting advanced logistics planning tools.

Improving Volumetric Efficiency of Containers:

The company redesigned packaging to minimize wasted space and customized containers to suit specific product dimensions.

Improving Space Utilization of Boxes:

Hero MotoCorp adopted strategies such as optimizing box size and dismantling vehicles for the best space utilization of boxes.

| For cost- competitiveness, Hero MotoCorp developed the 4i Model, a systematic approach aimed at optimizing resource utilization across its export operations. It is a cyclic model which focuses on improvement in material productivity. |

Incorporating Alternate Materials and Technology:

Hero MotoCorp introduced lightweight and durable materials and leveraged advanced manufacturing technologies to enhance precision and efficiency.

For delivering World-Class Quality, the team developed a second model called the Quality Chakravyuh. The term ‘Chakravyuh’ comes from the Mahabharata and describes a circular military formation that is highly strategic and difficult to penetrate or escape.

The Quality Chakravyuh is a comprehensive, multi-layered approach to achieving defect-free manufacturing. Inspired by the concept of a strategic, impenetrable defence mechanism, this framework integrates continuous monitoring, problem-solving, and process optimization to deliver world-class quality in export operations.

The Quality Chakravyuh focuses on multiple interconnected elements, each addressing critical aspects of quality. It is a structured framework designed to eliminate defects and ensure continuous improvement. The Chakravyuh begins with Quality Controls at the input level, involving 100 percent inspection of parts.

At the input stage, the company ensures the implementation of Poka-Yoke across all its suppliers, confirming that 100 percent of electrical parts pass end-of-line testing after thorough inspection. Truly embracing the concept of continuous improvement, enhancements are consistently made at supplier levels and input gates to ensure that 100 percent quality parts reach the process level.

Hero MotoCorp provided advanced Technical Support to ensure seamless operations and maintain high-quality standards. Through these initiatives, the company has successfully established a reliable global network, promoting mutual growth and success.

Results Achieved

Through these concerted efforts, Hero MotoCorp has achieved remarkable outcomes:

- Cost Reduction: The company has realized significant savings in material and logistics expenses.

- Enhanced Quality: Hero MotoCorp delivers products that consistently meet and exceed customer expectations.

- Operational Efficiency: Streamlined processes have led to faster delivery times.

- Global Recognition: The company has strengthened its reputation as a leader in two-wheeler manufacturing.

|

BALWINDER SINGH |

|

PRABHSHARAN SINGH Deputy Manager Assembly- Operations Hero MotoCorp prabhsharan.singh@ heromotocorp.com |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe