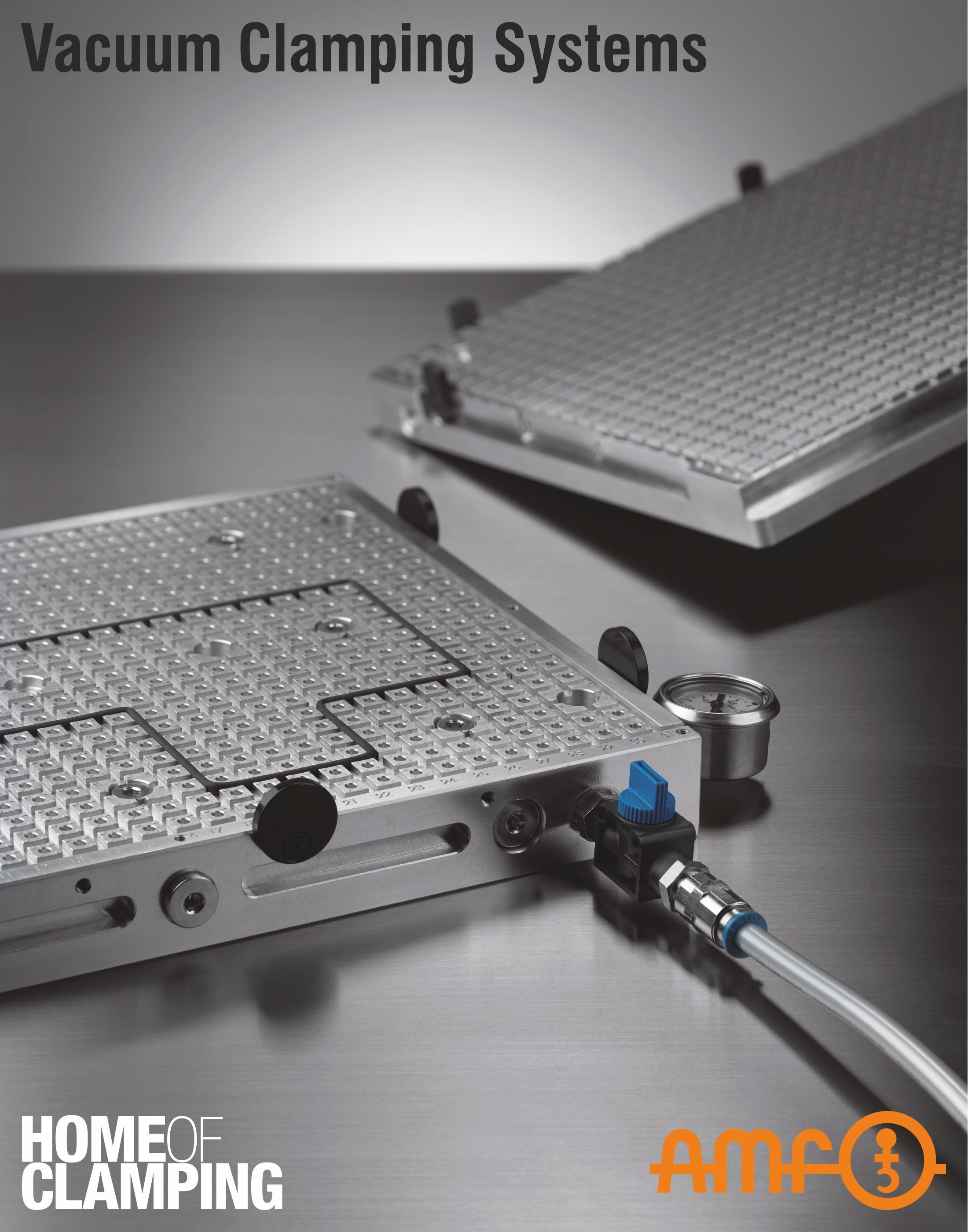

Vacuum Clamping Systems

Vacuum Clamping Plates By AMF

AMF vacuum clamping systems are widely used in the wood, plastic, glass, ferrous and non-ferrous metal industries for quick clamping and simple machining. They are also used to clamp workpieces during engraving, grinding, assembly and polishing. They are particularly suitable for machining or processing plates, allowing all five sides of a clamped plate to be machined in a single setup, including holes or pockets.

In vacuum clamping, a pressure differential is created which presses the workpiece against the clamping plate. Thus, the work piece is not, as one might think, actually ‘sucked’ in, but is rather pressed against the vacuum table. The sliding surface of the work piece depends on its surface structure, the pressure differential and the area on which the vacuum acts. A larger contact area results in greater holding forces.

AMF Vacuum clamping plates can be operated using compressed air and venturi nozzle or with an external pump, offering low compressed air consumption and, thus, reduced operating costs. By means of individual grid allocation, it is also possible to clamp and machine multiple, different workpieces at the same time. Additionally, AMF vacuum clamping systems can be integrated into the AMF ‘Zero Point Clamping System’, size K20.

Standard plate sizes range from a minimum of 150 x 150 mm to a maximum of 400 x 600 mm, with larger sizes available upon request.

ANDREAS MAIER Workholding Technology Pvt Ltd

www.amf.de

Hall & Stall: 4A/C-120

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe