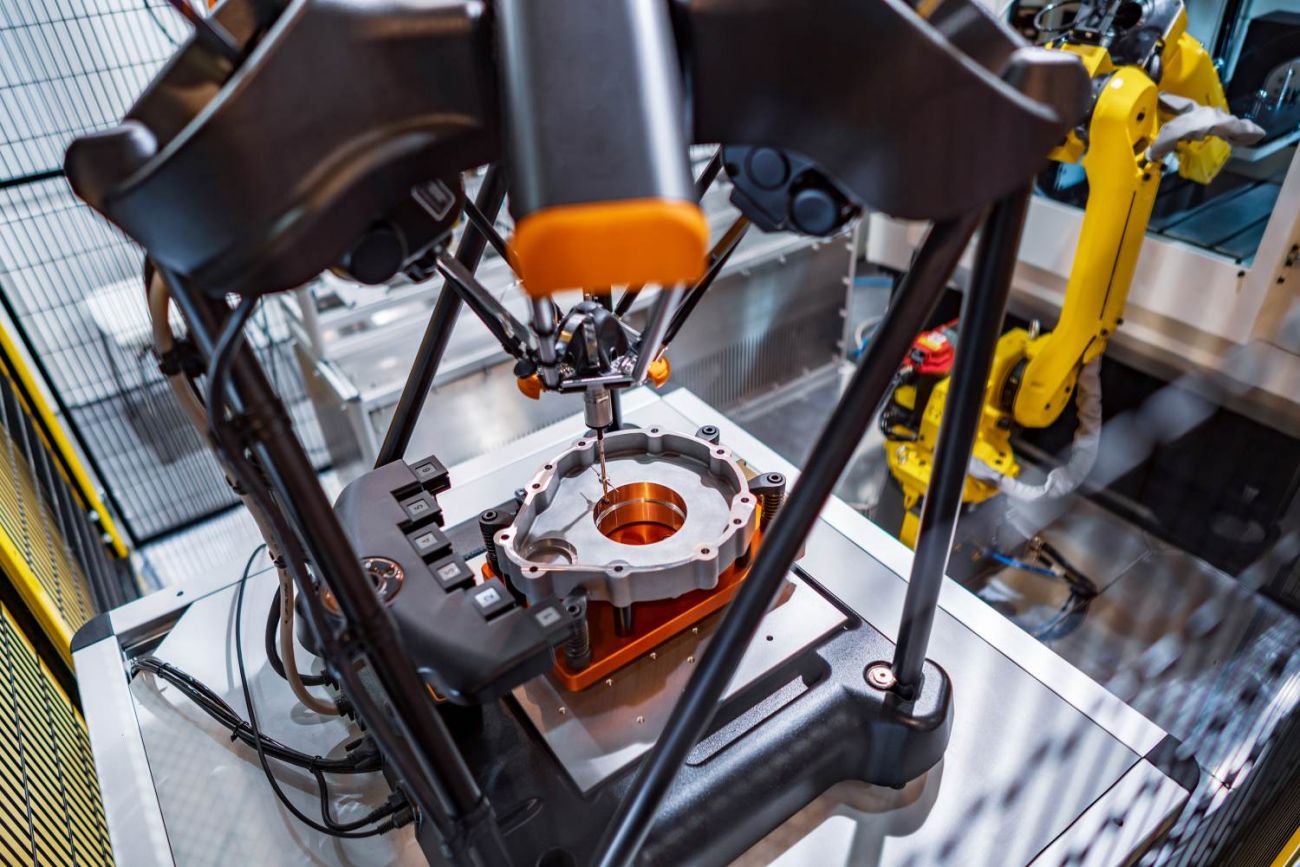

Gauging Systems

Renishaw’s Equator with Automation

The fast-paced manufacturing environment demands a high-speed and flexible gauging. Renishaw’s Equator delivers versatile inspection of medium to high-volume manufactured parts in key applications across diverse industries while reducing time and cost, for example transmission components for automotive and landing gear for aerospace. Equator gauging systems play an integral part in supporting manufacturers’ drive to develop their own smarter processes and embrace factory automation.

The Equator system can operate at a temperature range of 5 – 50°C and up to 80 percent humidity and has been optimized for part loading via a robot or shuttle system. Configured for easy communication between the system and a variety of automated work cell equipment, integration into an automated cell is simplified. The result is significantly reduced cycle times, improved productivity, and increased throughput.

The Equator range is compatible with new IPC software which allows constant monitoring and automatic adjustment of a machining operation, keeping part dimensions close to nominal and well within process control limits. This correction of process drift improves part quality and manufacturing capability and reduces scrap. The proximity of the Equator gauge to the CNC process allows adjustment at the point of manufacture, avoiding time delays or reliance on the finished part (tailgate) inspection. The Equator gauging system can be connected to one or multiple CNC machine tool controllers.

Renishaw Metrology Systems Ltd

www.renishaw.com

Hall & Stall: 4A/B-101

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe