5-axis Machining Centers

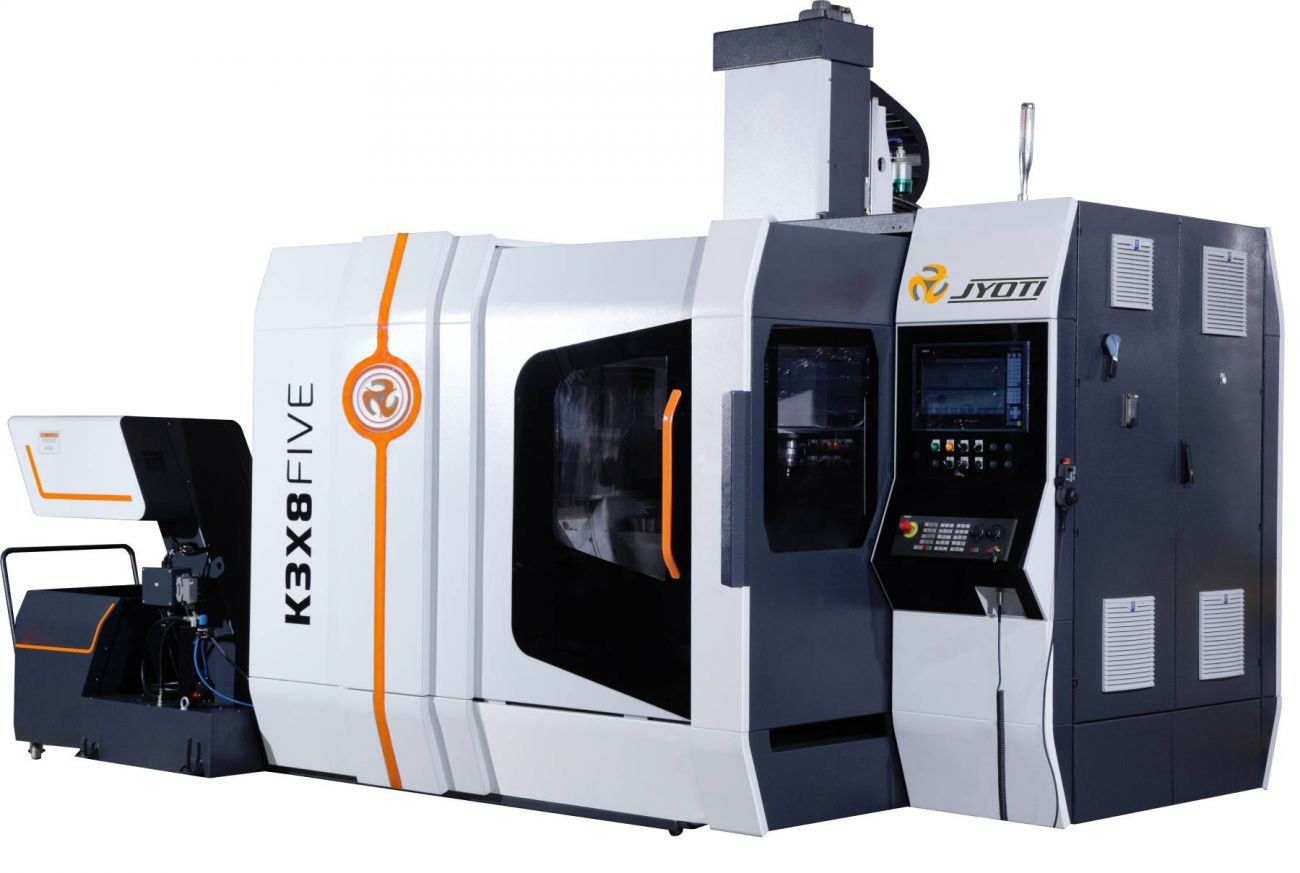

Jyoti CNC’s Versatile K3X8 FIVE

In order to provide simultaneous 5-axis operations and a seamless transition from roughing to finishing across a wide range of complex, high-precision applications, the KX Five Series integrates a high-speed machining (HSM) architecture. For all machining processes, its fixed portal structure ensures an ideal combination between dynamic performance and exceptional accuracy, leading to superb surface quality.

The KX Five Series' high-performance electro-spindle guarantees quick metal removal rates, increasing machining efficiency. The rotary table's 55° inclination capacity, made possible by its TRIM technology design, allows for negative angles that improve operational flexibility.

With a work surface of φ 500 mm and a rotating speed of up to 50 rpm, the table may be precisely tilted from +30° to -180°, providing flexibility for intricate machining needs. Several variants with several pallet options and an automatic tool changer (ATC) are available in the KX Five Series, which greatly increases production.

This series, which was created especially to satisfy the requirements of high-integrity mechanical parts, complex aerospace components, and injection molds, ensures remarkable efficiency and versatility in a wide range of precision machining applications.

Jyoti CNC Automation Ltd

www.jyoti.co.in

Hall & Stall: 5/A-122

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe