Gear Manufacturing

Revolution in Motion: Ace Designers Joins the Gear Manufacturing Arena at IMTEX 25

Ace Designers is the largest producer of CNC machines in India. It has an installed base of more than 80,000 machines globally. The company has a right range of high-volume products and complete basket of appropriate products for multiple segments. It has created a huge infrastructure to address needs of large volume products and low volume special requirements. Ace Designers’ focus has always been to fill up the gaps felt by customer in different market segments and also on timely introduction of products to satisfy the perceived product configuration and technology needs.

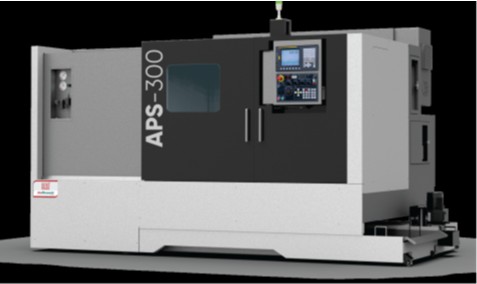

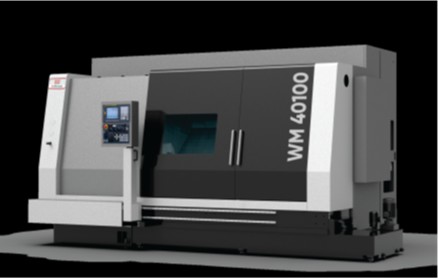

For decades, Ace Designers has been synonymous with innovation in CNC Turning solutions, producing high-performance CNC lathes, Turn-Mills and Tooled up solutions. At IMTEX 25, the brand is taking a significant leap forward by unveiling two cutting-edge machines – APS 300 Power Skiving Machine and WM 40100 Worm Milling Machine – offering solutions for in the gear manufacturing domain.

Leveraging Legacy for a New Era

This transition reflects Ace Designers’ philosophy of continuous innovation and customer integration. Drawing from its vast experience in building large CNC machines, ACE Designers has extended its engineering excellence into the gear segment to meet growing customer productivity demands.

APS 300 Power Skiving Machine: Redefining Gear Manufacturing

Designed for internal gear manufacturing, this machine combines shaping and milling principles with high-speed machining advantages. It delivers precision, efficiency, and versatility, making it ideal for volume production.

- Enhanced Capability: Supports modules up to 3 mm with a swivelling cutter spindle angle of ±30° (manual setting), providing unparalleled flexibility for diverse applications.

- Precision and Speed: Combines shaping and milling principles. With high-speed machining to deliver exceptional accuracy and reduced cycle times.

WM 40100 Worm Milling Machine: Precision for High-Module Worms

Tailored for worm shaft production, this machine offers advanced capabilities for high-module threads. It ensures synchronous operation between the cutter and workpiece, enabling the efficient production of complex profiles with exceptional accuracy.

- Wide Machining Range: Capable of performing worm milling on shafts up to 400 mm in diameter. It can also be used for form milling Spur and helical gears of large modules.

- High Module Capability: Supports modules up to 6mm in a single pass, ensuring efficiency for larger thread profiles. Higher modules(upto 25) can also be cut with multiple passes.

- Flexible Cutter Orientation: Offers a cutter orientation angle of -30° to +210° (horizontal), enabling versatility across applications.

- Robust Design: Built to handle demanding operations with stability, ensuring precision and reliability for heavy-duty applications.

Driving Value with Customer-Centric Solutions

By leveraging its proven expertise and robust technology base, Ace Designers not only delivers innovative products but also reinforces its commitment to empowering customers with reliable, high-quality, and cost-effective solutions, along with a comprehensive range of turning machines.

Ace Designers Ltd – Turning Centre Division

www.acemicromatic.net

Hall & Stall: 5/B-109

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe