Gear Testing Systems

Marposs’ NVH G-EAR at IMTEX 2025

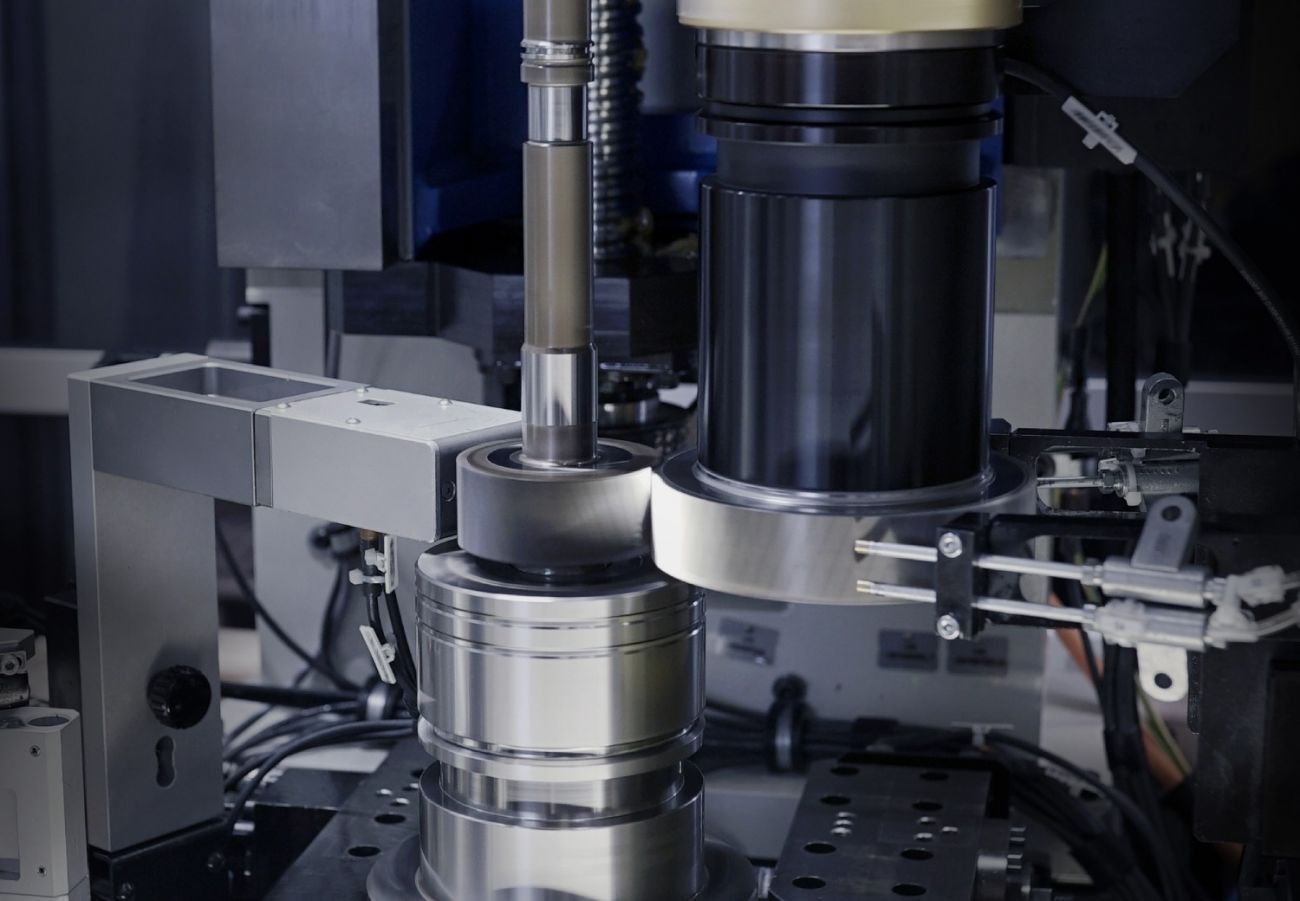

At IMTEX 2025, Marposs is presenting one of its most valuable applications for gear measurement and testing: the NVH G-EAR machine.

With the growing adoption of hybrid (HEV) and fully electric vehicles (EV), drivetrain noise has become a major challenge for car manufacturers. In battery electric vehicles (BEVs), a silent gearbox not only ensures the mechanical reliability and efficiency of the electric drive unit but also enhances driver comfort.

For achieving a silent gearbox, it is paramount to test each individual gear 100 percent prior to the assembly of the transmission or gear reducer. Identifying potential noisy gears at this stage results in significant time and cost savings for manufacturers.

The ideal solution for gear noise testing in a manufacturing environment is the Marposs NVH G-EAR, a machine that is capable to test parts under challenging operating conditions (3000 rpm rotation speed, 40 Nm torque) using a special master gear that engages with the part based on the Single Flank rolling action.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe