CAD/CAM System

ENCY CAD/CAM System

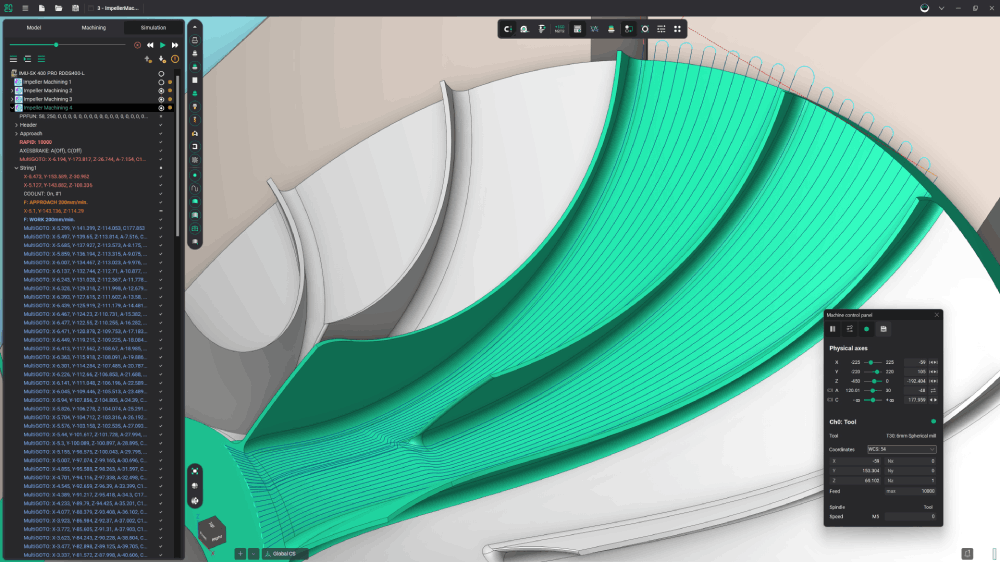

ENCY is a CAD/CAM for a new generation that combines advanced CAM technology with an intuitive user interface and natural workflow.

Serving industries like aerospace, automotive, and consumer goods, ENCY delivers precision tools for 2D/3D modeling, toolpath generation, simulation, and G-code verification tailored for CNC machining.

Key Features:

- Optimized Toolpaths: Supports 2D, 3-axis, 5-axis, and mill-turn operations with machine-specific optimization, leveraging machine capabilities for enhanced precision and efficiency.

- High-Fidelity Simulation: Solid and voxel-based simulations replicate material removal, additive processes, and painting, while detecting collisions and out-of-gauge issues to prevent costly errors.

- NC-Code Verification: Validates G-code to catch errors early, reducing machine downtime and ensuring reliable execution.

- Stock Tracking: Tracks material removal to prevent redundant cuts and improve machining efficiency while maintaining accuracy.

- Digital Twin Creation: Enables accurate machine setups, including tools and fixtures, for streamlined project transfers and setup consistency across operations.

- Cloud Collaboration: ENCY Cloud connects programmers and operators for real-time project sharing, fine-tuning, and troubleshooting.

ENCY empowers industries with tools to streamline manufacturing, optimize workflows, and achieve consistently accurate, efficient machining processes. Its capabilities minimize risks, enhance productivity, and support the most demanding precision-manufacturing applications.

ENCY Software Ltd

www.encycam.com

Hall & Stall: 7/A-108

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe