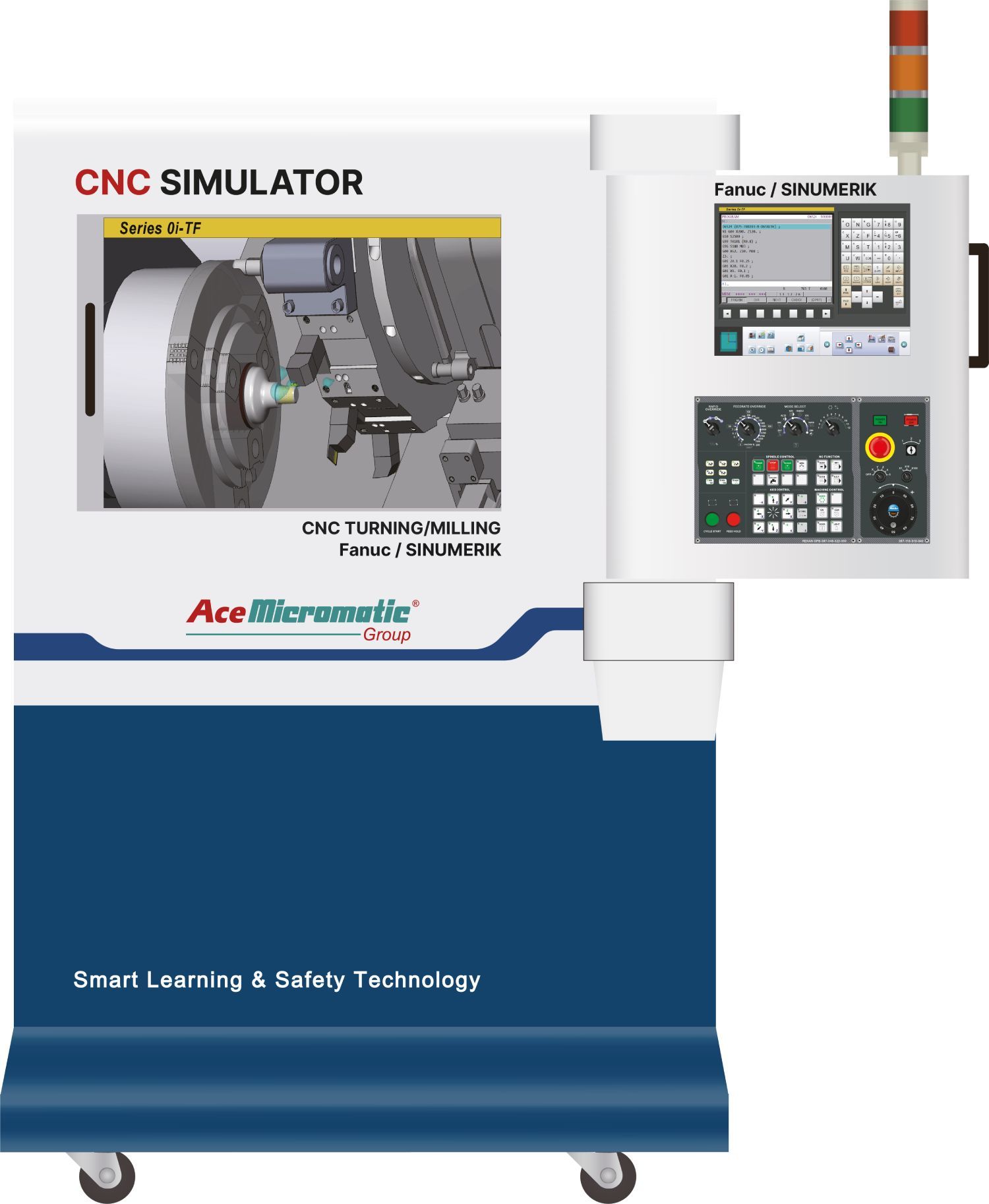

CNC Simulators

Empowering Skills, Ensuring Safety

The CNC Simulator—Machine and Desktop—versions are essential tools for both education and the industry. For schools and training centers, these simulators offer a safe, hands-on way for students, operators, and enthusiastic machinists to learn CNC programming and machine operations without the risk of damaging expensive equipment. This practical experience helps prepare them for real-world jobs.

In the professional world, the CNC Simulator is a valuable asset. It allows companies to create and test CNC programs before using real machines, which reduces mistakes, saves time, and uses resources more efficiently. Features like error detection and collision avoidance make sure programs are safe and effective, boosting productivity.

The CNC Simulator is also cost-effective. It cuts down on material waste and machine wear and tear, leading to significant savings. For research and development, it provides a virtual space to try out new machining processes without incurring high costs and thus, encouraging innovation.

At IMTEX 2025, the company is showcasing the Simulator, both the Desktop version as well as the Training Machine, with versatile features for upskilling CNC programming targeting engineering, diploma, and ITI students.

Overall, the CNC Simulator—Machine and Desktop—versions enhance learning, improve efficiency, and promote innovation in CNC machining. Their realistic simulations, easy-to-use interfaces, and advanced features make them valuable tools for education and industry alike.

Ace Designers Ltd

www.acemicromatic.net

Hall & Stall: 5/B-109

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe