IIoT-based Machine Monitoring Systems

Leanworx: Transforming Machine Monitoring

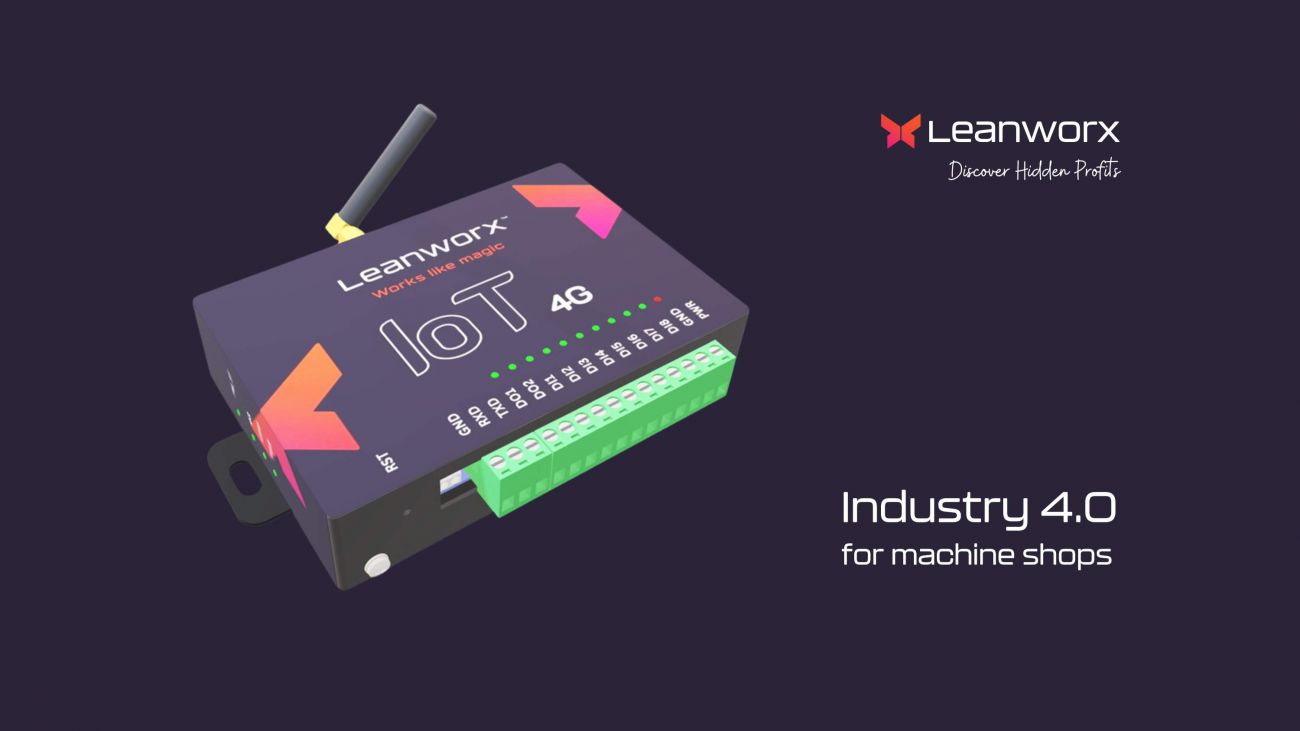

Leanworx is an IIoT-based machine monitoring system designed to deliver accurate, real-time insights that reduce waste in machine utilization and manpower. Traditional manual production monitoring often involves delays and outdated data, sometimes arriving 48 hours post-crisis. Leanworx automates this process using Industry 4.0, eliminating inefficiencies and providing instant, actionable insights.

Its AI-powered platform tracks downtime, monitors OEE, and manages production through an intuitive interface. The system is cost-effective, adaptable, and compatible with any machine—modern CNCs, legacy tools, die-casting machines, or any machine—ensuring seamless integration and informed decision-making.

What sets Leanworx apart? Its design philosophy is encapsulated in T.R.U.M.P: Tamper-proof, Reliable, Universal machine interface, Maintenance-free, and Plug-and-Play. These principles ensure innovation, security, and scalability.

Leanworx caters especially to MSMEs, which often lack IT infrastructure. It connects machines directly to the cloud, eliminating the need for internet, LAN cabling, servers, or dedicated IT personnel. Setup takes just 30 minutes, making it a simple, efficient solution for enhancing shop floor productivity. One of Leanworx’s best features is that it costs less than a cup of coffee per day.

Leanworx Technologies Pvt Ltd

www.leanworxcloud.com

Hall & Stall: 7/C-110

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe