Leading the Vacuum Revolution

Prasanth Sakhamuri, Managing Director, Hind High Vacuum (HHV) Group, India’s premier vacuum, optics, and thin-film technology company, in the following interview with MMI’s Editor-in-Chief, Soumi Mitra, recounts HHV’s extensive and dynamic journey, milestones that define it, and junctures that have led to its diversification while celebrating the company’s ability to identify market gaps, the several firsts in the list of its achievements, the National R&D award from the President of India and so much more.

The Hind High Vacuum (HHV) Group is India’s premier Vacuum, Optics, and Thin-film technology company. Could you please provide an overview of your offerings and their applications in various industries, and elaborate how HHV has diversified into fields such as solar module manufacturing, thin film coating services and equipment development, and optics fabrication?

Over its 60-year history, HHV has been a pioneer in the manufacturing of vacuum pumps, solar panels, cryogenic vessels, and vacuum flasks. As the country’s first vacuum technology company, HHV has consistently met domestic needs, especially during times of high-tech product shortages. During India’s time under technical embargo with the limited flow of high-tech production and severe foreign exchange shortage, many technologies like solar, thin film coating, and optics fabrication had to be homegrown.

The HHV Group operates across several critical sectors, including Space, Aerospace, Automotive, and Defence. It comprises five companies, including HHV Thermal Technologies, with five decades of expertise in vacuum furnace design and manufacturing for heat treatment, brazing, and annealing; and HHV Advanced Technologies, specializing in thin-film coating machinery and optics fabrication for both R&D and production applications.

| HHV's one significant early venture was the production of stainless steel vacuum flasks for international markets. It provided valuable insights into international expectations and quality standards. |

Founded in 1965, HHV Group has come a long way from being a small-scale business establishment to a global enterprise employing 800 individuals with sales and service centers worldwide and multi-acre plants in Bangalore. Could you briefly take us through the milestones that have led to your current juncture in the industry?

HHV’s journey has been extensive and dynamic, and we initially focused on mastering diverse technologies and their applications. Early milestones include building India’s first space simulation chamber and thin film coating system. These initial leaps and risks allowed us to push ourselves to establish technology quickly and for a purpose.

One significant early venture was the production of stainless steel vacuum flasks for international markets. While the business ultimately struggled against cheaper imports due to unfavorable industrial policies, it provided valuable insights into international expectations and quality standards.

We then shifted focus to the Solar industry, initially developing thin-film coating equipment for space-qualified solar cells. This transition led to the creation of India’s leading solar module manufacturing facilities, reflecting HHV’s growing expertise in renewable energy technologies.

In the early 2000s, HHV began contract manufacturing for Edwards High Vacuum. When Edwards was acquired, HHV seized the opportunity to license and purchase thin-film manufacturing technology, which expanded our international presence.

You have had several firsts in the list of your achievements: developing and manufacturing India’s first high vacuum rotary pump in 1968, launching India’s first commercial ALD reactor in 2017, and most recently in January 2024, developing India’s first Indigenous vacuum coating unit and successfully installing a 3.7 m telescopic mirror coater at Mount Abu, contributing to numerous strategic projects and research initiatives in the country. How do you identify these gaps in the market?

Our ability to identify market gaps stems from our deep expertise and commitment to advancing domestic manufacturing capabilities. We recognize that numerous everyday products, from smartphones to automobiles, rely on components that are coated or heat-treated using vacuum technology.

Our journey began with a dream to fabricate zoom lenses, which required vacuum coating technology. In the 1960s, faced with limited access to materials and knowledge, we developed our own equipment to meet this need, inadvertently expanding into machine building. Today, we manufacture the machines and produce the high-precision zoom lenses we originally envisioned.

With 60 years of experience, we continually adapt to advancements in process technology. Collaborations with institutions, such as IIT Bombay, have led to developments like our ALD (Atomic Layer Deposition) system. Our expertise in developing telescopic mirror coatings has also become highly respected.

Our drive to innovate is fueled by customer demands and the multi-use nature of vacuum technology in critical fields such as defence, atomic energy, and space. Our advancements are fueled by commercial needs, business opportunities, and partnerships with research institutions.

It must be a matter of immense honor to have received the National R&D award from the President of India for establishing the production of thin film metalized substrates. Kindly share the experience and the effort that led to it.

|

Receiving this award from the President of India was a great honor. Since its inception, HHV has embraced a ‘Make in India’ attitude. We have been instrumental in the production of thin film metalized substrates, a key component for the Hybrid Micro Circuit (HMC) program. This involves coating thin alumina wafers with metal inside a vacuum chamber, followed by lithography and dicing. These substrates are essential for space flight applications. Our metalized substrates are used in every ISRO satellite launch, including the Chandrayaan Mission, where they even reached the moon. We are incredibly proud that our work supports ISRO’s groundbreaking space research and missions. This award underscores HHV’s role in fostering indigenous capabilities and aligns with the Government of India’s Aatmanirbhar (self-reliant) program. We are honored to contribute to this national vision and continue supporting advancements in technology and space exploration. |

|

You have made a mark in the space arena with your innovations such as an indigenous space simulation chamber to test leaks in pallets and allied components for rocket thrusters. You also have received Space Qualifications for Lithograpy of HMC substrates. Could you elaborate on your developments in this field?

Our advancements in space technology have been significant. The Lithography HMC substrates were part of a technology transfer from ISRO. While the Space Applications Centre (SAC) could fabricate these substrates in small R&D batches, the growing demand led to the decision to collaborate with HHV to establish a dedicated facility. This partnership reduced SAC’s reliance on imports, decreased costs, and provided a reliable domestic production source.

In addition to the lithography facility, HHV has developed specialized capabilities for the Space sector. We pioneered the creation of indigenous space simulation chambers capable of high vacuum and temperature cycling to replicate deep space conditions, which significantly cut costs previously incurred from overseas testing.

We also constructed a hypersonic wind tunnel in Trivandrum for simulating flight and reentry conditions up to 14 times the speed of sound. Additionally, we manufacture equipment for producing carbon-carbon composite components used in spacecraft engines and body shields.

These contributions underscore HHV’s role and commitment toward advancing indigenous space technology and supporting the space department's needs.

| The award from the President underscores HHV’s role in fostering indigenous capabilities and aligns with the Government of India’s Aatmanirbhar program. Honored to contribute to this national vision, it commits to continue supporting advancements in technology and space exploration. |

The 60th-anniversary celebration at HHV Peenya (Bengaluru) facility featured an exhibition where each company within the group showcased new products and developments achieved in the past year. The Group’s Managing Directors also shared the challenges in the high technology department. Our readers would be keen to know the challenges and your plan to overcome them.

Today’s key challenges include a shortage of skilled labor and inadequate infrastructure. Despite having a large potential workforce, there are too few skilled individuals in technical fields. This shortage impacts our operations, as we face higher costs and difficulties in managing the movement of goods, people, and services.

|

Our supply chain also struggles with the availability of high-tech materials, requiring us to import nearly all critical components for advanced work, such as optics and vacuum technology. A comprehensive policy is needed to address these issues by aligning national demand with capacity building, both in terms of workforce and materials. The Union Budget’s emphasis on ‘Make in India’ aims to strengthen internal ecosystems and support public sector undertakings. Additionally, the increased allocation for the Department of Science and Technology will further support these goals. |

|

In 2023, HHV underwent a demerger, creating two 100 percent subsidiaries: HHV Thermal Technologies for furnaces and carbon composite businesses, and HHV Advanced Technologies for thin films and optics businesses. Can you elaborate on how it has impacted the operations and strategic focus of each subsidiary?

HHV has a strong track record with successful joint ventures (JVs) and demergers. Demerger strategies allow each entity to develop tailored growth plans based on its specific product line, customer base, and market potential. While the businesses share a common foundation in vacuum technology, they serve different applications and operate on distinct cycles.

This approach also facilitates strategic partnerships and customized business plans, accommodating different growth rates and management styles. In a rapidly evolving business environment, flexibility and focused management are crucial for laying strong foundations and achieving sustained growth.

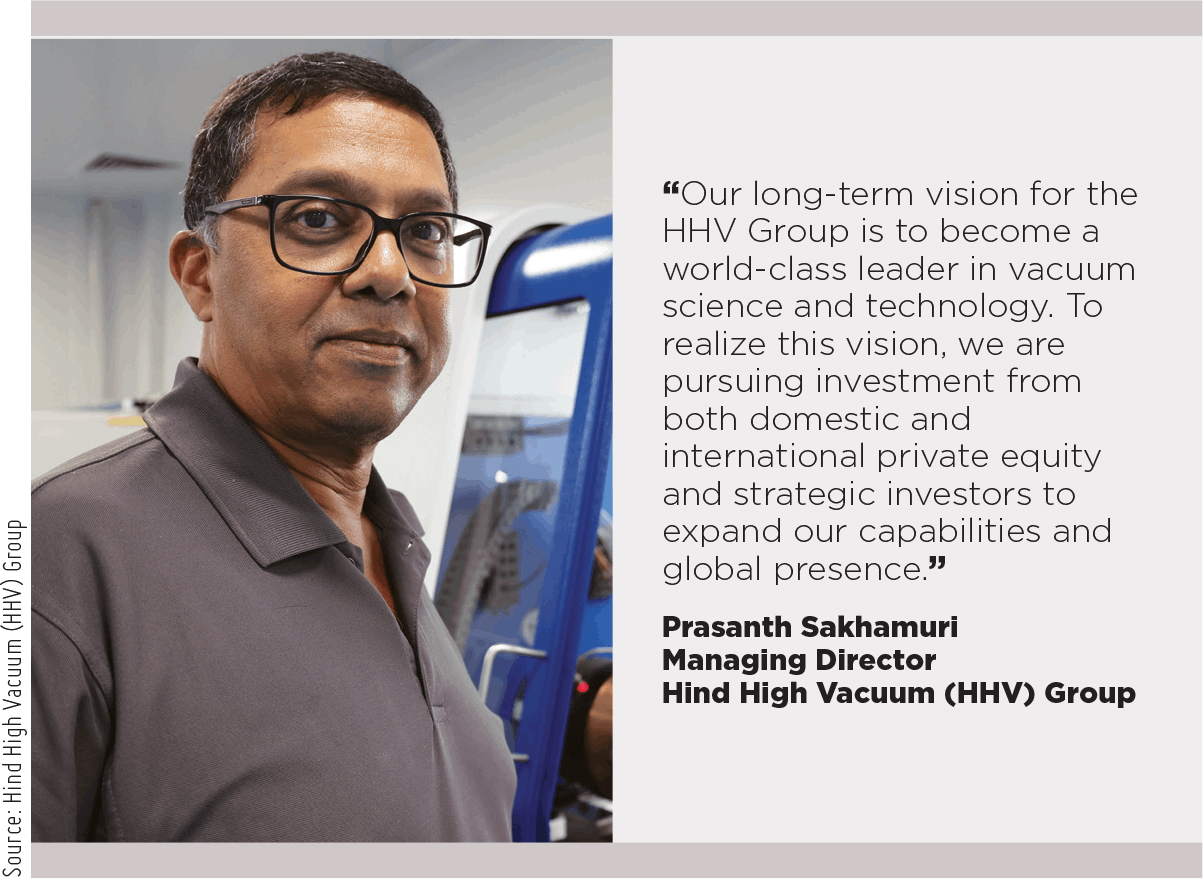

What are HHV Group's plans for investment and growth, and what is the long-term vision for the Group and its subsidiaries?

Our long-term vision for the HHV Group is to become a world-class leader in vacuum science and technology. To realize this vision, we are pursuing investment from both domestic and international private equity and strategic investors to expand our capabilities and global presence.

Additionally, we are partnering with educational institutes to develop a comprehensive ecosystem for skill development, ensuring a steady pipeline of talented professionals. We are also exploring joint ventures to diversify into semiconductor and solar equipment, aligning with significant investments happening in India. These strategic moves will not only enhance our technological expertise but also support our goal of driving innovation and growth in these critical sectors.

Please share your views on how the Union Budget 2024 will impact the Indian manufacturing sector.

The Union Budget's strong emphasis on ‘Make in India’ is set to boost the development of our internal ecosystem by encouraging PSUs and other organizations to strengthen domestic manufacturing capabilities. Increased funding for the Department of Science and Technology will drive innovation by supporting R&D, enhancing competitiveness, and helping Indian manufacturers advance up the value chain.

Moreover, investment in skill development and training programs is crucial. By addressing skill gaps through targeted vocational training and educational initiatives, we can improve productivity and better align the workforce with the needs of the Manufacturing sector. This comprehensive approach will not only support current industry demands but also foster long-term growth and competitiveness.

| HHV is partnering with educational institutes to develop a comprehensive ecosystem for skill development. It is also exploring joint ventures to diversify into semiconductor and solar equipment, aligning with significant investments happening in India. |

Source: Hind High Vacuum (HHV) Group

|

SOUMI MITRA Editor-in-Chief Modern Manufacturing India soumi.mitra@magicwandmedia.in |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe