In Search of Sustainable Solutions

This academic project explores the development of innovative steel foams made from machining waste through microwave sintering and the addition of carbamide. These foams, designed for the automotive industry, offer superior energy absorption capabilities, significantly enhancing vehicle safety in crash situations.

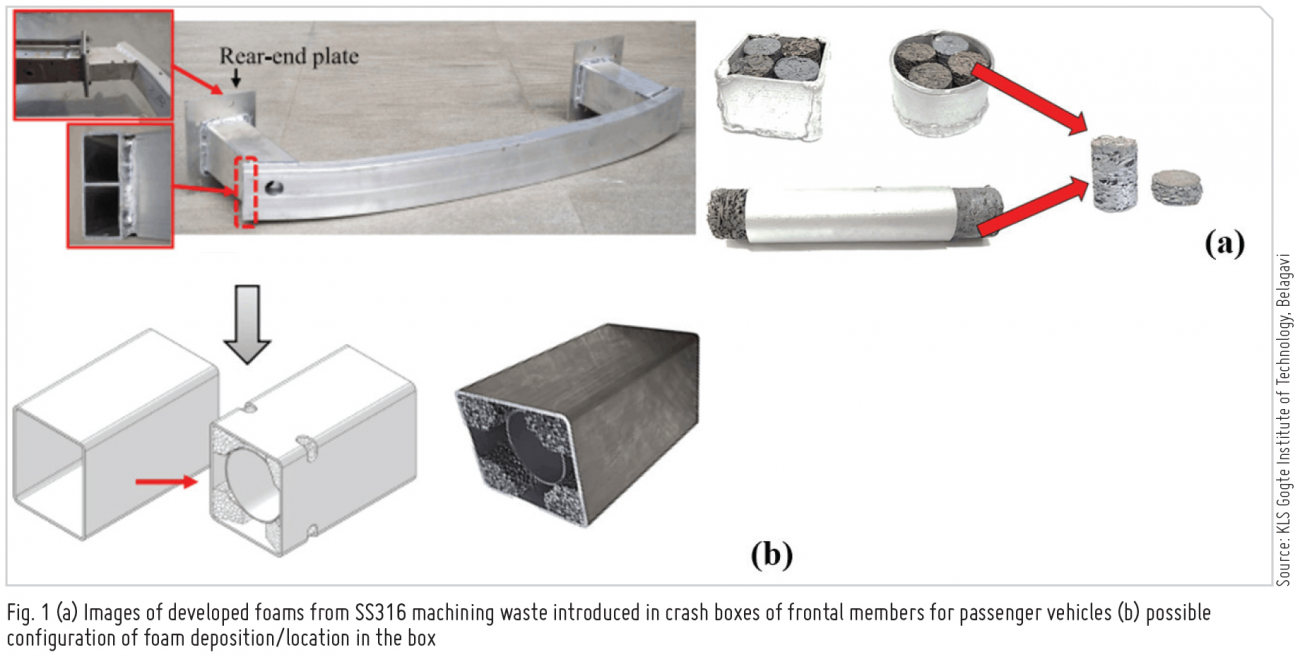

The proposed work focuses on developing novel steel foams derived from machining waste using innovative Microwave Sintering techniques and the inclusion of carbamide to enhance foaming characteristics. These foams present a groundbreaking opportunity for the Automotive industry due to their exceptional specific energy absorption capabilities compared to those currently available in the market. As a result, they hold significant potential for enhancing passenger vehicle safety in India. By incorporating these foams into crash boxes (Fig. 1), the industry can substantially improve safety ratings, making vehicles more impact-resistant and potentially saving lives. This innovative approach not only promotes sustainability through the utilization of waste but also raises safety standards in the rapidly evolving automotive landscape, ensuring a safer future for all.

Key highlights of the work and methodology

- Development of foams from machining waste by setting different parameters of temperature, soak time, and compaction pressure using a hydraulic press to consolidate the machining waste/scrap into the required dimensions referring to the ASTM standards and then microwave sintered to obtain the end product.

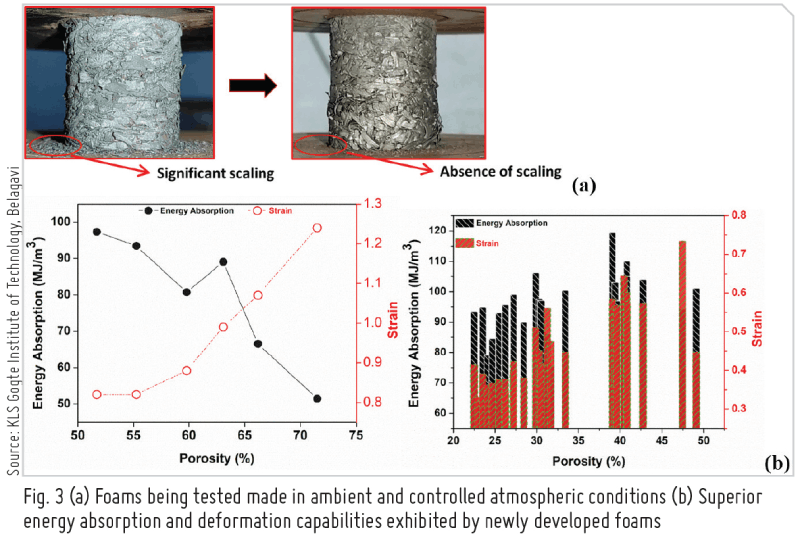

- Choosing the optimal parameters and amount of carbamide for machining chips + carbamide specimens and the layer-by-layer combination of hybrid specimens for the best results in terms of energy absorption (Fig. 3 b), strain, and reduced cycle time.

- Compression testing of the specimens made (Fig. 3 a), followed by computation and analysis of results.

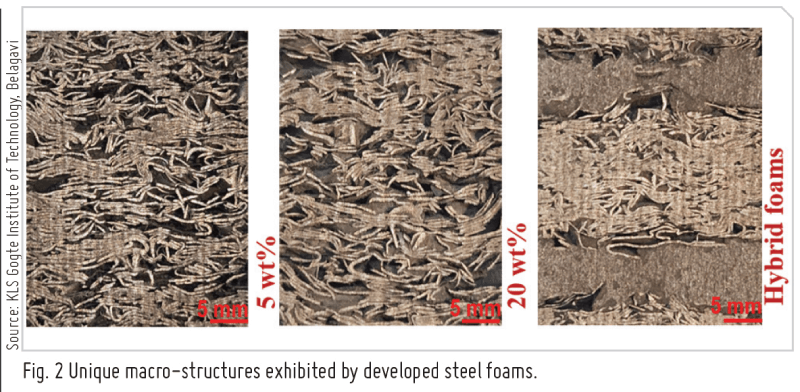

- Macro-structural analysis of the foams (Fig.2).

A significant outcome of the work

|

Higher Energy Absorption: Values of up to 90 MJ/m3 can be observed for 100 percent strain which is significantly high compared to the existing foams in the market and based on the data obtained from the reported scientific work. Specific Energy Absorption (SEA) of up to 30 KJ/Kg has been observed, which is high compared to existing crash boxes used for automobiles. |

Weight Reduction: A significant amount of weight was reduced in all the types of foams experimented on during this project, particularly, machining chips with urea foams which have 76 percent weight reduction compared to an SS 316 bulk material of the same dimensions. Further, the weight reduction based on the density parameter is also on the lower side compared to the foams available in the market.

Higher Straining Capabilities: A deformation of about 75 percent of the initial height was observed with a maximum strain of 1.24 in the case of chips plus urea samples and an average of 0.5 strain in the case of plain machining chips foam and higher strains of 0.7 in hybrid foams which exhibited a combination of strain and energy absorption.

Reduced Cycle Time: The overall cycle time for manufacturing a single foam was less than an hour whereas the data from the literature survey indicates an average cycle time for a foam of around 2 to 3 hours and some cases even more.

Highly Economical: Since the end product was manufactured from machining waste, the cost of raw material was significantly reduced in comparison to that produced by powder metallurgy. Further, a hybrid microwave sintering processing route was employed, which, additionally reduced the overall consumption of kilowatt-hours during

the manufacturing cycle.

Typical product applications of developed foams

The developed steel foams have a wide variety of applications in different fields. For example, they are used in automobile bumpers for crash protection and in batteries for weight reduction. Metal foams are also used in medical applications as prosthetics, as filtration and catalysis devices at high temperatures, as sound absorbers in the field of acoustics, for radiation protection, and in ship fenders for impact protection.

| Among these applications, steel foam is particularly well-suited for automobile crash protection. This is owing to its unique property of withstanding very high damage with relatively lesser deformation. Steel foams can be placed in the frontal and side sections of a car as anti-intrusion bars (Fig. 1) or in the crash box (attached to the bumper) to absorb sudden impacts caused by abrupt and sharp deceleration of the vehicles in the event of the crash, thereby increasing passenger safety. |  |

Typical results have shown that individual foams can absorb up to 119.865 MJ/m³ of energy, meaning that when 3-4 foams are placed inside a crash box, the total impact energy absorbed will be much higher. A combination of different foams (such as plain, hybrid, and urea-mixed) can be arranged side by side or diagonally to achieve higher energy absorption and significant strain. However, the arrangement of the foams depends on the shape and structure of the crash box. Crash boxes can vary in shape and size depending on their application. Some common types include square, rectangular, circular, slender hollow, and honeycomb-shaped crash boxes.

| Steel foam is particularly well-suited for automobile crash protection. This is owing to its unique property of withstanding very high damage with relatively lesser deformation. |

|

DR VINAYAK MALIK Associate Professor Department of Mechanical Engineering KLS Gogte Institute of Technology, Belagavi |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe