Optimizing Operations and Customer Experience

The New Relic State of Observability for Industrials, Materials, and Manufacturing report shows that 44 percent of respondents say the adoption of AI technologies is driving the need for observability, with 65 percent able to resolve incidents faster after adoption.

New Relic, the intelligent observability platform, published its State of Observability for Industrials, Materials, and Manufacturing report, which offers insights and analysis on the adoption and business value of observability. The report is based on insights from 285 technology professionals and was developed in association with the 2023 Observability Forecast. It shows that manufacturers are investing in observability to optimize uptime and improve productivity, cross-team collaboration, and strategic decision-making.

The report highlights the importance of implementing full-stack observability, with respondents reporting a higher return on investment (ROI) after adoption. Additionally, 65 percent of industrial, materials, and manufacturing respondents said their mean time to resolution (MTTR) has improved since adopting observability. The report found that the primary strategies and trends driving observability include security (50%), AI technologies (44%), and IoT technologies (43%).

As manufacturers across India accelerate their digital transformations, they are recognizing the critical role of observability in optimizing operations and customer experience. Forward-thinking manufacturers are gaining a competitive edge by leveraging full-stack observability to enhance operational efficiency, mitigate risks, and deliver superior customer experiences.

| The report is based on insights from 285 technology professionals and was developed in association with the 2023 Observability Forecast. It shows that manufacturers are investing in observability to optimize uptime and improve productivity, cross-team collaboration, and strategic decision-making. |

Observability and AI drive industry advantages

| As the Manufacturing industry enters the Fifth Industrial Revolution, there is a strong focus on adopting new technologies to create a competitive advantage. Close to half (44%) of manufacturing organizations said AI technologies were driving observability needs. The powerful combination of technologies like observability and AI are creating greater insights into telemetry data and are crucial to addressing the surmounting complexities of growing data sets. Observability is critical to the success of AI, since it helps teams understand their telemetry data, offers ways to improve MTTR, and enables developers to easily apply fixes to code-level errors in their integrated development environment (IDE). It also increases automation for rapid alerts while improving incident detection and resolution. |

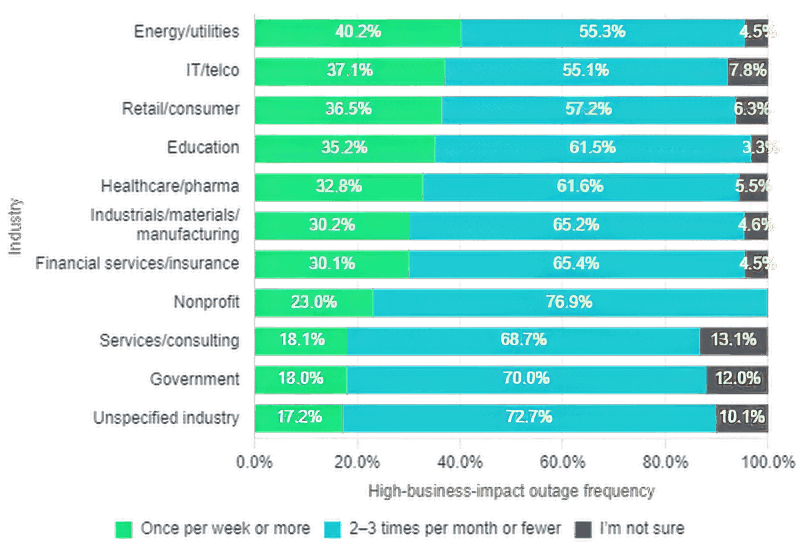

High-business-impact outage frequency by industry |

Observability is key to reducing outages

|

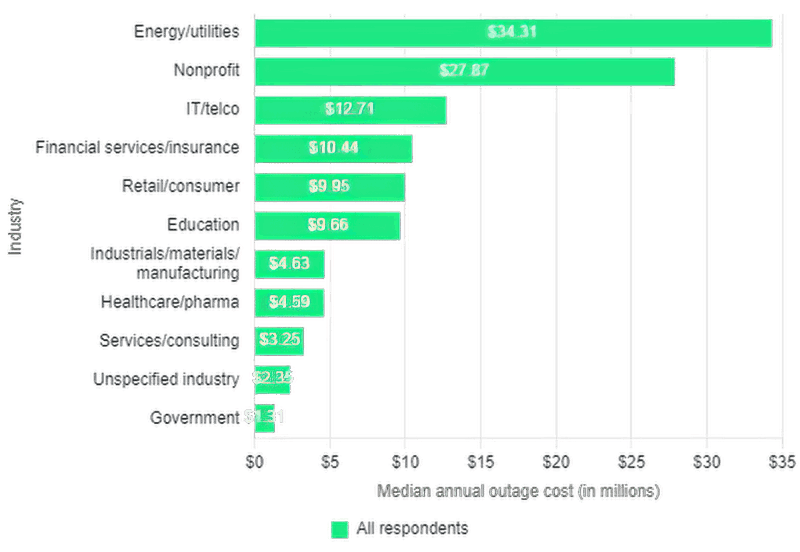

Median annual outage cost by industry |

Manufacturing organizations that had achieved full-stack observability saw a substantial rate of improvement in MTTR, with 34 percent reporting an improvement of 25 percent or more since adopting observability. These organizations also experienced less frequent high-business-impact outages, with 30 percent reporting outages at least once a week, compared to the average of 32 percent. Additionally, just 12 percent of responses estimated outages cost their organizations more than US$ 1 million per hour compared to 21 percent overall. |

Investments in observability drive productivity

More than half (51%) of manufacturing organizations said that observability improves cross-team collaboration and strategic decision-making. When it came to what improved their life the most, nearly half (47%) of practitioners said observability increases productivity and that they can find and resolve issues faster.

“New Relic is a critical component in our DevSecOps cycle. New Relic will allow us to normalize the process of driving continuous application and service improvement through observing the user experience, which is key for any project and moves beyond setting and forgetting after deployment,” said Mitsuhiro Mabuchi, Ph.D, Group Manager, Cloud CoE Grp., DS System Development Dept., Advanced Data Science Management Div., Advanced R&D and Engineering Co., (Concurrently Lead of the CCoE Virtual Team at the Direct Reporting Digital Transformation Promotion Dept.), Toyota Motor Corporation.

|

PETER MARELAS Field CTO APJ, New Relic |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe