For a Leak-Free World

An interesting account of how Air Power East, a specialist in providing high-quality compressed air systems, resolved a dual challenge with an innovative approach from FLIR to maintain its commitment to quality and efficiency while addressing the specific needs of its clients…

Air Power East, a family-run business with over 30 years of experience as a premier distributor of Atlas Copco, specializes in providing high-quality compressed air systems to various industries across East Anglia. Under the leadership of Jason Sewell, the company has established a strong reputation for delivering reliable and efficient solutions.

However, the company faced a significant challenge in ensuring its systems were completely leak-free, a concern shared by its clients, including an agricultural manufacturer managed by Paul Musgrove. Sewell highlighted the issue, stating, “Customers have been asking us to make sure that we can prove something is completely leak-free.”

Concurrently, Musgrove was seeking an effective way to manage and maintain their compressed air systems, with a specific focus on reducing energy waste and operational costs, emphasizing the need to ‘save money where we can, especially with energy prices as they are.”

This dual challenge called for an innovative approach to maintain Air Power East’s commitment to quality and efficiency while addressing the specific needs of its clients.

Finding a Solution

|

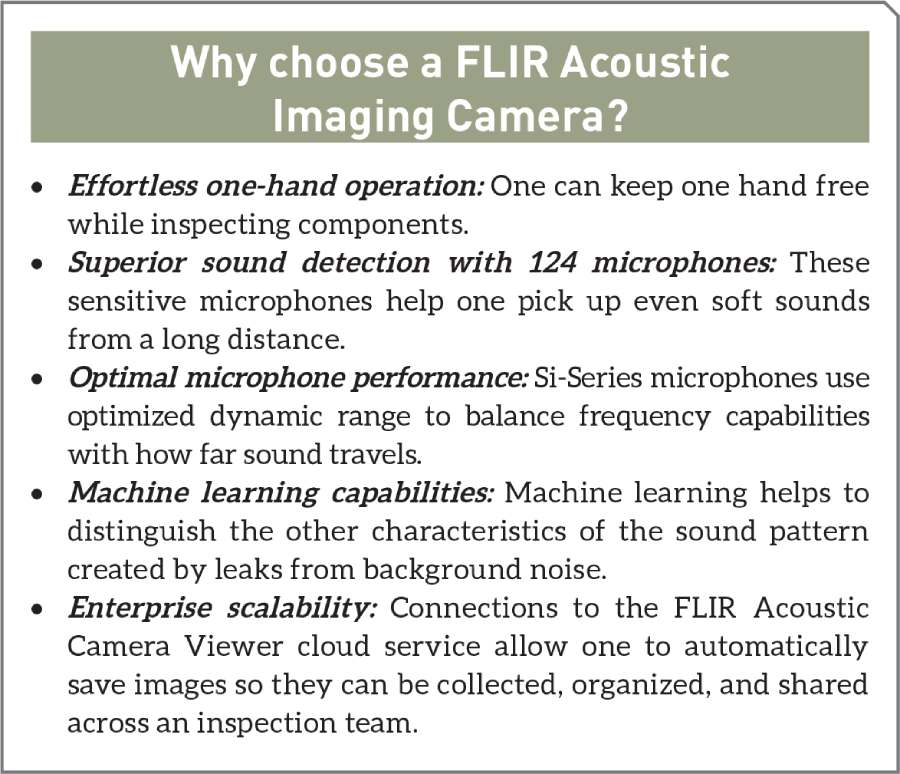

To address the intertwined challenges, Sewell reached out to Baseline-RTS, an independent supplier of training and predictive maintenance equipment. The company introduced Air Power East to FLIR Si-Series cameras: advanced acoustic imaging tools capable of accurately detecting air leaks. Sewell explained, “We sat down and did a bit of market research on a few different models and then came to the top. So, we contacted FLIR to come along and show us the FLIR Si124, and we have loved it ever since.” The Si124 is a lightweight, one-handed tool designed to quickly locate pressurized leaks in compressed air systems or detect partial discharge from high-voltage electrical systems. It is equipped with 124 microphones to produce a precise acoustic image that visually displays ultrasonic information. This image is transposed in real time on top of a digital camera picture, allowing users to accurately pinpoint the source of sound. |

FLIR Si-Series |

| FLIR Si-Series cameras can detect issues up to 10 times faster than traditional methods, even in loud industrial environments. They are also compatible with the FLIR Thermal Studio suite for offline editing, analysis, and advanced report creation, and can help facilities save money on utility bills and delay the expense of installing new compressors. |

FLIR Si-Series cameras can detect issues up to 10 times faster than traditional methods, even in loud industrial environments. Additionally, they are compatible with the FLIR Thermal Studio suite for offline editing, analysis, and advanced report creation, and can help facilities save money on utility bills and delay the expense of installing new compressors.

|

The use of the Si124 camera brought about transformative results. Sewell explained the camera’s effectiveness: “We have managed to walk around with the customer, showing them exactly what we are Quantitative results underscore the Si124’s impact. The camera enabled the detection of leaks amounting to approximately 100 cubic feet per minute (CFM), which is roughly 50 liters per second. This translates to about 18.5 kW of compressor power, leading to substantial energy and cost savings, particularly in light of rising energy prices. |

FLIR Si-Series cameras are equipped with 124 microphones which produce an acoustic image that is then superimposed in real time on a digital camera picture.

| This case study demonstrates the effectiveness of advanced tools in solving intricate industrial problems and highlights the importance of technology-driven solutions in optimizing industrial processes. |

Conclusion

Air Power East’s adoption of the FLIR Si124 camera to address the complex challenges in compressed air systems illustrates the power of innovative technology in industrial settings. The successful detection and rectification of air leaks not only enhanced operational efficiency but also led to considerable energy and cost savings for the agricultural manufacturer. This case study demonstrates the effectiveness of advanced tools in solving intricate industrial problems and highlights the importance of technology-driven solutions in optimizing industrial processes.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe