Kays Engineering Exhibits Advanced Gundrilling Technologies at IMTS 2024

Kays Engineering, Inc. will be exhibiting at the upcoming IMTS 2024 show, scheduled for September 9-14, in Chicago, IL, USA. The company showcases its American-made gun-drilling machines from its three brands: DeHoff, Eldorado, and TechniDrill. It will be displaying these machines in its booth at IMTS, booth number #338373.

Dehoff Gundrilling Used to Make World’s Largest Nuclear Fusion Reactor

The DeHoff 20144 is a custom-designed gun drilling machine used to make components for the world’s largest nuclear fusion reactor, the ITER Tokamak. Fusion reactors use extreme heat to fuse atoms together and create massive amounts of energy, while also not creating any radioactive waste nor any carbon dioxide or greenhouse gas emissions.

The DeHoff 20144 is used to perform gun drilling, pull boring, roller burnishing, and thread tapping on the aluminum microwave guides. The microwave guides are long tubes used to heat the plasma fluid inside the Tokamak vacuum chamber to 150 million degrees Celsius, which are the conditions needed for nuclear fusion.

|

The DeHoff 20144 has a gun drilling diameter capacity of 2 inches (50.8 mm) and a maximum drilling depth of 144 inches (3,658 mm). It features custom workpiece fixturing and tooling to perform the gun drilling, pull boring, roller burnishing, and thread tapping operations all on a single machine. DeHoff gun drilling machines are designed and manufactured by Kays Engineering in Marshall, Missouri, USA. Teledyne Brown Engineering, as the prime on a contract to supply US-ITER, based at Oak Ridge National Laboratory, has ordered DeHoff 20144 to fabricate waveguides for the ITER reactor, which will be located in Cadarache, France. |

|

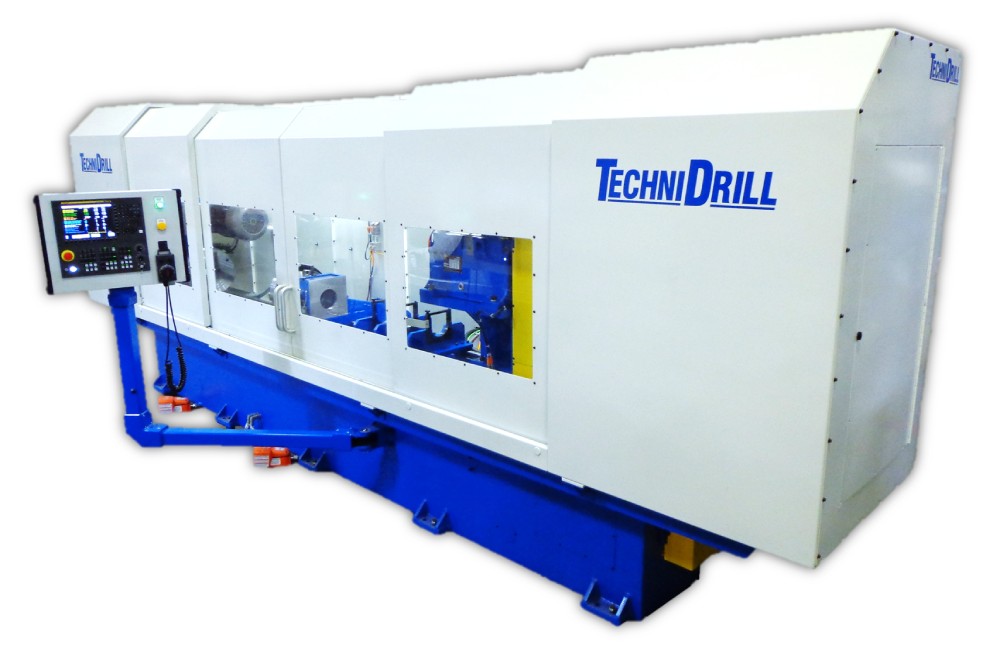

TechniDrill Gundrilling Machine for Aerospace Applications

The TechniDrill 2.00-30-48 is a gundrilling machine used to manufacture airplane aileron actuation cylinders. The actuation cylinder starts as a solid bar. The gundrilling machine drills the large primary hole in a single pass, without the need for a pilot hole. Secondary processes are then utilized to finish the cylinder.

The TechniDrill 2.00-30-48 has a gundrilling diameter capacity of 2.0 inches (50.8 mm) and a maximum gundrilling depth of 48 inches (1219 mm). It features a 30-horsepower AC spindle motor and two-speed gearbox to provide versatile gundrilling performance. The workpiece is counter-rotated during gundrilling via pneumatically operated 3-jaw chucks, which increases the accuracy of the drilled hole.

TechniDrill gundrilling machines are designed and manufactured by Kays Engineering in Marshall, Missouri, USA.

Eldorado Gundrilling Machine with New Fixturing Design

The Eldorado M75-30 gundrilling machine features a new design for its counter-rotation fixturing assembly. During the gundrilling process, the workpiece is held in a fixturing assembly that rotates the part in the opposite direction of the gun drill rotation. This ‘counter-rotation’ of the workpiece improves the accuracy of the gundrilling process. The new fixture design includes a gear motor assembly that is more powerful and durable than the previous design.

The Eldorado M75-30 has a maximum gundrilling diameter of 0.75 inches (19 mm) and a maximum drilling depth of 30 inches (762 mm). The machine features a box-way design as opposed to linear guideways. This results in superior vibration damping, extended tool life, and improved surface finish. Eldorado machines are designed and manufactured in the USA.

|

The Eldorado M75-30 gundrilling machine features a new design for its counter-rotation fixturing assembly. During the gundrilling process, the workpiece is held in a fixturing assembly that rotates the part in the opposite direction of the gun drill rotation. This ‘counter-rotation’ of the workpiece improves the accuracy of the gundrilling process. The new fixture design includes a gear motor assembly that is more powerful and durable than the previous design. The Eldorado M75-30 has a maximum gundrilling diameter of 0.75 inches (19 mm) and a maximum drilling depth of 30 inches (762 mm). The machine features a box-way design as opposed to linear guideways. This results in superior vibration damping, extended tool life, and improved surface finish. Eldorado machines are designed and manufactured in the USA. |

Image Source: Kays Engineering

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe