Edwards Vacuum Launches EDP 80-400 Dry Pump Series

Burgess Hill West Sussex, UK – Edwards Vacuum, one of the leading vacuum manufacturers, has been successful in the field of environmentally friendly, dry-running vacuum pumps for decades. This is evidenced by more than 100,000 installed systems that offer comprehensive benefits to customers in the chemical, petrochemical, and pharmaceutical industries worldwide. These include vacuum applications in drying, distillation, evaporation, polymerization, and biofuel production. Edwards vacuum solutions ensure safe pumping without deposits and corrosion, as well as simple maintenance concepts.

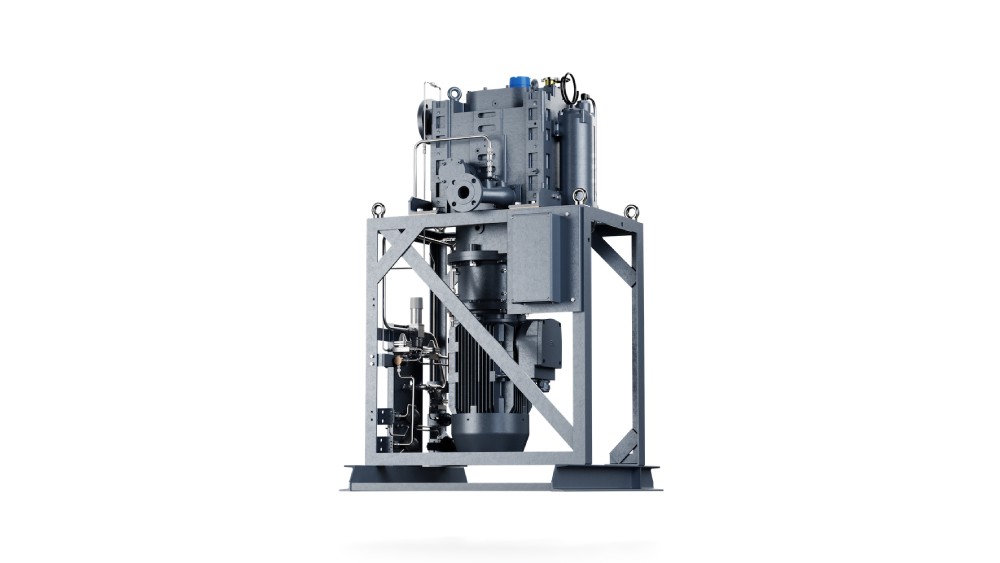

Functional Design, Long Service Life

Among these dry EDWARDS models are the oil-free EDP 80 - 400 vacuum pumps for the chemical industry. The design of this reliable series is based on non-contacting reverse claw technology. This ensures a uniform vacuum with high efficiency and low operating costs. Thanks to its vertical design, the pump prevents the accumulation of particles and thus ensures long-lasting performance.

Safe Under the Toughest Conditions

“Available in pumping speed classes 80, 160, 250, and 400 m3 h-1, these dry pumps minimize the risk of process and wastewater contamination, as is often the case with ‘wet’ vacuum technologies,” explains Megha Ajmal, Product Manager, Edwards Vacuum. “They are built to the highest safety standards and have been tested to meet the relevant explosion-proof certification required by most applications in the chemical industry,” adds Ajmal. Another benefit is that the EDP vacuum pump is temperature-controlled to ensure optimum operating conditions—hot for corrosive applications and cold for other gasses.

Minimum Service Life: 25 Years

“All EDP models are designed for a minimum service life of around 20 years and can even be operated for one year without supervision. A cycle of three years is sufficient for reconditioning. This results in a significant reduction in the total cost of ownership,” says the Product Manager summarizing a key benefit. To ensure that the vacuum pump maintains its performance standard over its entire service life, Edwards Vacuum also offers a wide range of customized service solutions for EDP models for all applications.

Specific Service

Edwards also offers users a specific system design and construction service that is tailored precisely to the respective application. Prefabricated modules can be combined with comprehensive CAD solutions. The service also includes the subsequent expansion and reconfiguration of the systems. The range of modules includes condensers, dust filters, shut-off and throttle dampers, and flame arresters. The need for special accessories is also covered. The work can also be realized in accordance with the customer’s specific requirements as well as local or industry-specific regulations and practices. “We also prepare complete documentation on the specifications and carry out certifications if required,” emphasizes Ajmal in conclusion.

The EDP models have so far proven themselves in the following vacuum applications, among others: Drying, Distillation, Reactor operation, Solvent, Recovery, House/central vacuum, Evaporation, Polymerization, Ethylene oxide sterilization, Biofuels, Corrosive and flammable gasses, Absorption/desorption, Crystallization, and Filtration.

Image Source: Edwards

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe