MAXIMIZING EFFICIENCY

Thermal imaging cameras require little training for an operator, and the investment in a camera, operator training, and associated reporting software may cost less than one may think. Read on to learn why using them is so crucial.

Product quality is high on the priority list of any reputable manufacturer. Whether one’s business manufactures finished articles or components for other businesses to incorporate into their products, the risks are the same. If one’s production equipment fails, their business quickly transitions from a profitable organization to a loss-making company.

Many businesses are used to keeping a healthy level of reserve stock in the warehouse to ensure their customers are never let down in the event of an unplanned break in production. But as competition increases and margins erode, most businesses choose to tie up as little cash in stockholding as possible, making reserve stock a less efficient way to operate in today’s highly competitive environment.

As businesses hold less stock, the effect of disruption to production is quickly compounded, deliveries are more likely to be missed, and customers are let down. This not only impacts revenue from lost business, but it also damages the reputation of a business.

Industries, such as the Automotive industry, face severe supply fines if they fail to deliver on time. Many modern car production lines can produce a car every 90 seconds so a one-hour shut-down results in 40 cars not being produced. If the average price of a car is €35,000 then this type of incident would result in a lost revenue of €1.4 million. As a result, it is not difficult to understand the high fines associated with missed delivery deadlines.

But can these issues be avoided in the first place? We believe the answer is yes; carefully monitoring the condition of one’s production equipment on a regular basis has shown that many supply chain problems can be eliminated.

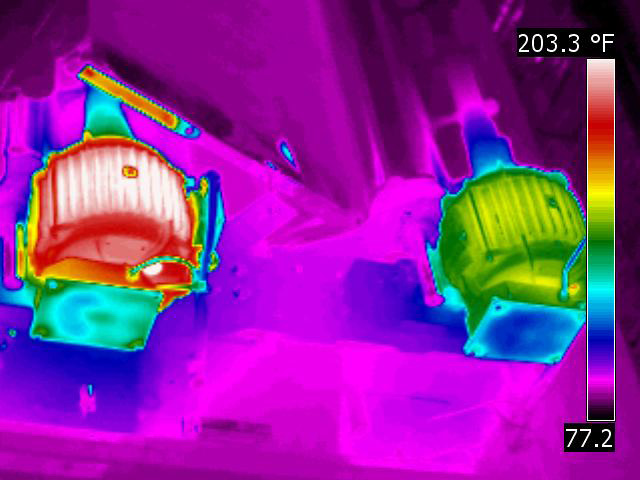

For example, if one’s business uses an electric motor at any stage during the production process, when was it last checked for cleanliness? Electric motors can overheat due to a buildup of dirt and debris blocking airflow holes that are designed to help cool the motor. The motor may not be old or have any obvious issues. In fact, it may appear to be working perfectly well until it suddenly fails.

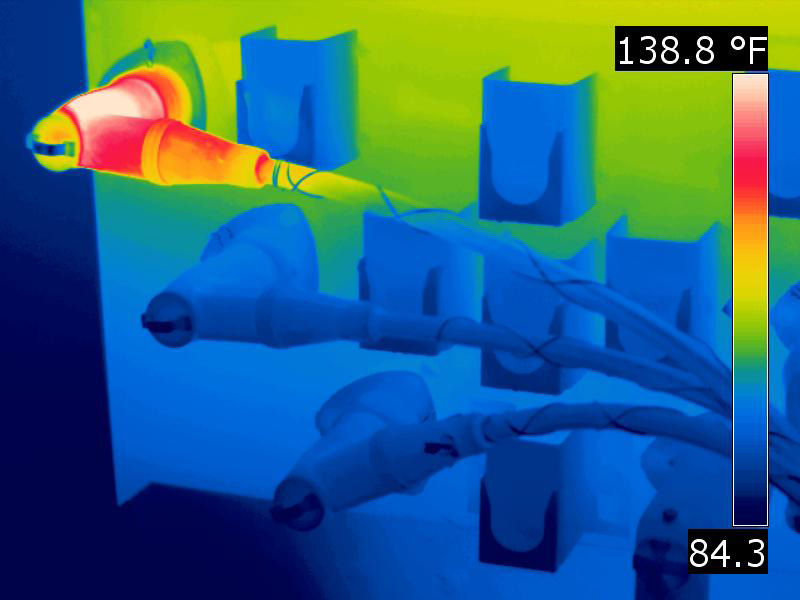

Other examples might be electrical connections, fuse boxes, contactor plates, or other components found in electrical cabinets. Over time, tiny vibrations and heat cycles can cause crimped connections to loosen, along with nuts and bolts on connective wiring which give rise to elevated temperature as the electrical resistance increases. This type of common fault has no visual clues and can happen at any time during the production process, yet in most cases can be prevented using predictive condition monitoring techniques.

With thermal imaging, one can quickly tell the motor on the left is running hot and know to move in for further inspection. |

Poor electrical connections can be easily identified before they cause production halts. |

Thermal imaging cameras: a key component in reducing unscheduled downtime

If regular thermal inspections are undertaken, thermal signatures can be identified for every electrical connection, electric motor, other electric component, or moving equipment in a facility. While equipment operates as intended, temperatures will remain reasonably consistent, and the insights gained will be no more than regular reassurance. However, if suddenly a temperature reading begins to unusually increase, then this may be indicative of a developing fault.

|

FLIR offers a variety of both handheld and fixed-mount thermal cameras, as well as analysis software to fit one business’s condition monitoring needs. |

|

FLIR produces a range of thermal cameras, with products such as the FLIR E8 Pro having seamless cloud-based backup and file transfer through to FLIR Thermal Studio reporting software. |

As mentioned earlier, correcting faults may be as simple as tightening a connection or cleaning cooling fins or airways but faults may be more severe and require more detailed maintenance or component replacement.

In the example of an electric motor exhibiting higher temperatures due to a build-up of dust and dirt, the fix may take 5 minutes when the motor has been turned off to clean it thoroughly. If the issue isn’t identified early, the motor may fail from deterioration and require a replacement motor to be installed, potentially resulting in a shutdown over several days while waiting for a new motor to be delivered.

Thermal cameras require little training to use in the hands of an operator, and the investment in a camera, operator training, and associated reporting software may cost less than one may think. The one certainty is that the overall cost will be less than an unplanned production shutdown.

FLIR produces a range of thermal cameras, with products such as the FLIR E8 Pro having seamless cloud-based backup and file transfer through to FLIR Thermal Studio reporting software.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe