FOR RESPONSIBLE PRODUCTION

Marposs’ New Smart Factory SW is intuitive, web-based, and equipped with new features. It consists of five modules, each specializing in one aspect of a factory.

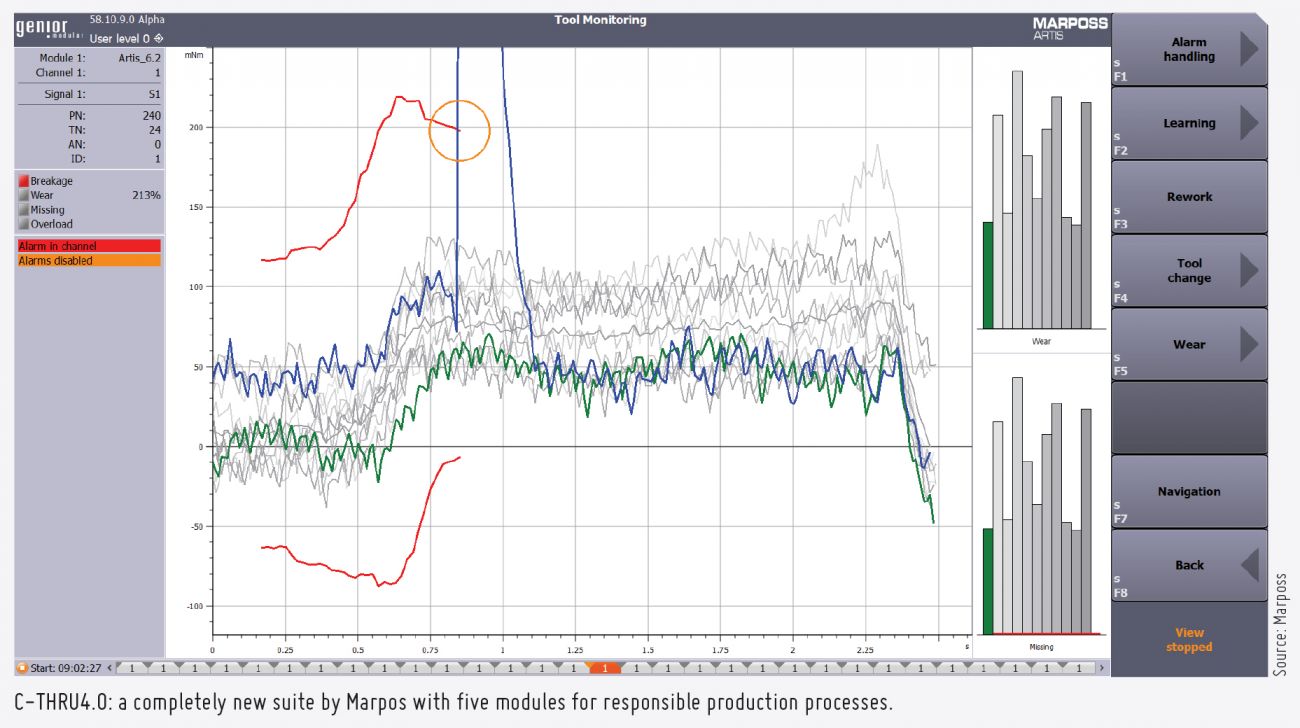

To provide data evidence for decisions and assist in the optimization of a factory, Marposs has introduced its new Smart Factory SW. For over 10 years, Marposs’ C-THRU4.0 has shown its capabilities to improve the machining process, avoid scrap, and provide quality evidence for the components.

The new suite maintains the C-THRU4.0 name but is otherwise completely new. It is intuitive, web-based, and equipped with new features. It consists of a suite of modules, with each specializing in one aspect of a factory.

The five modules

There are five modules, each oriented to help make the production process responsible:

- C-Analyze is designed to optimize the work of the machines (process, setup, lines, quality problems), to provide traceability of the process and for predictive maintenance.

- C-Tooling is to optimize the tooling, including the tool life, usage, and choice.

- C-OEE is meant to prioritize and analyze the causes of production loss, mostly productivity and machine uptime.

- C-Energy is the tool used to monitor and optimize the energy consumption of all equipment in a factory. It is also designed for the fulfillment of ISO 50001:2018.

- C-Probe facilitates centralized reading of touch probe measurements and establishes limits to verify the machining results across the entire shop floor.

This unique suite of SW tools for the technical personnel of a factory is designed to highlight process anomalies. It uses a friendly graphic interface to identify and choose ways to optimize. This reiterative process leads to an increase in the efficiency of a factory in each of the module areas.

Other advantages of the software suite include offering insights into factory operations and verifying the effectiveness of improvement measures, as well as benchmarking against past performance or between different lines, machines, and shifts.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe