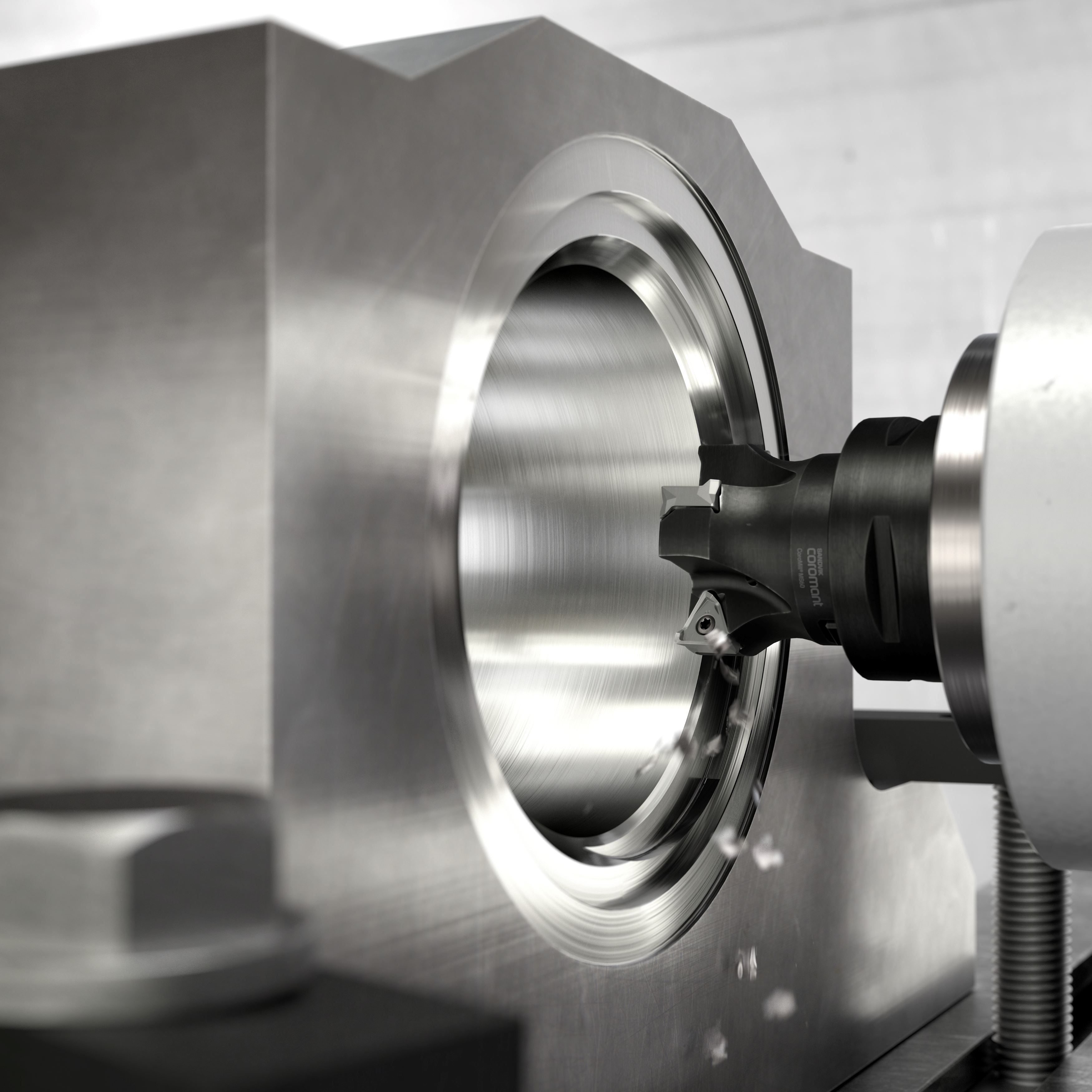

Sandvik Coromant Introduces CoroMill® MS60 for Efficient Shoulder Milling Operations

Sandviken, Sweden – Sandvik Coromant presents the latest addition to its family of milling tools: CoroMill® MS60. The tool is tailored for 90 degrees shoulder milling operations in steel and cast iron, but versatile enough to extend its competence across areas such as face milling and various ramping applications. “CoroMill® MS60 is a universal shoulder and face milling solution, primarily designed for roughing to semi-finishing operations in steel and cast iron, with two geometries capable of handling both these application areas as well as secondary areas ISO M and ISO S,” says Jocelyn Lanaro, Global Product Application Specialist, Sandvik Coromant. “As such, it is possible to handle mixed material batches, including stainless steel and nickel-based alloys, without changing inserts.”

As a robust multi-edge concept with positive cutting action, cutting forces are low for vibration-free machining, which translates into high cost-efficiency per edge. Featuring a true 90 degrees entering angle, CoroMill® MS60 is mainly a shoulder milling tool, even though it excels in many other areas as well. “From general milling operations to side milling, slot milling, helical ramping, and face milling, CoroMill® MS60 truly is an all-round solution,” says Lanaro. “It is usually the first tool chosen during the early stages of universal milling operations, handling the roughing to semi-finishing stages, leaving the finishing to dedicated solutions.”

Another standout feature to highlight is the direct pressed, six-edged inserts—as per Global Product Application Specialist: “They are manufactured using a highly advanced multi-axis pressing technology, meaning it has been possible to gather both a smooth cut and ramping capability in the same insert, enhancing the versatility of the product.”

Providing four different diameters in both metrics (50-100 mm) and inches (2-4 inch), CoroMill® MS60 offers a compact yet comprehensive selection, making both selection and usage easier.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe