THE EVOLUTION OF ROBOTICS

The evolution of robotics has been a fascinating journey. We take a closer look at the history of industrial robotics, the state of the industry currently and how robots might shape our world in the future.

The word ‘robot’ comes from the Czech word ‘robota’ meaning forced labor. Over a century ago, in 1921, the word was first used by Czech author Karel Capel for one of his plays titled ‘Rossum’s Universal Robots’.

The first known industrial robot dates back to 1937 when Griffith Taylor built a crane-like device capable of automating the stacking of wooden blocks from pre-programmed patterns. In 1954, the first industrial robotics patent was awarded to George Devol, who would come to be known as the ‘Grandfather of Robotics’.

George Devol

George Charles Devol Jr. was an American inventor, best known for creating Unimate, the first industrial robot. Devol’s invention earned him the title ‘Grandfather of Robotics’. In 1954, he applied for and was awarded a U.S. Patent for ‘Programmed Article Transfer’. The National Inventors Hall of Fame says, ‘Devol’s patent for the first digitally operated programmable robotic arm represents the foundation of the modern robotics industry’.

After receiving the patent, Devol searched for a company willing to give him financial backing to develop his invention. In 1956, Devol met Joseph Engleberger who was Chief Engineer of Manning, Maxwell, and Moore, and Engleberger agreed to license Devol’s patent to his company. However, the company was sold later that year but Engelberger sought a backer to finance the continued development of the robot under a new company, Unimation Incorporated, with Devol and Engelberger as co-founders.

Joseph Engleberger

Joseph Engelberger received his M.S. in Electrical Engineering in 1949 from Columbia University and is often referred to as the ‘Father of Robotics’.

As President and Co-founder of Unimation, Engelberger collaborated with Devol to engineer and produce an industrial robot under the brand name Unimate. The first Unimate robotic arm was installed at a General Motors Plant in Ewing Township, New Jersey, USA in 1961.

Chrysler and the Ford Motor Company soon followed General Motors’ lead by installing Unimate Robots in their manufacturing facilities. The first Unimate Robot was sold at a US$35,000 loss, but as demand increased, the company was able to begin building the robots for significantly less and began to turn a substantial profit.

By 1966, Engelberger expanded Unimation’s distribution internationally. Engelberger introduced robots to the European and Asian markets by granting licenses to Nokia of Finland and Kawasaki Heavy Industries (now Kawasaki Robotics) of Japan to manufacture and market Unimate robots, In the 70s and 80s, the Japanese took the lead by investing heavily in robots.

By the 80’s, many of the automotive companies that were Unimation’s early clients began to move away from the hydraulically powered Unimate robotic arms to robots powered by electric motors. Sales of Unimation fell and the company was eventually acquired by Westinghouse in 1982.

|

Tech Talks is a column by industry veteran and journalist Reji Varghese that talks about the latest advancements in Machine Tools, provides snippets from history, interesting facts, etc. about the Machine Tool industry. |

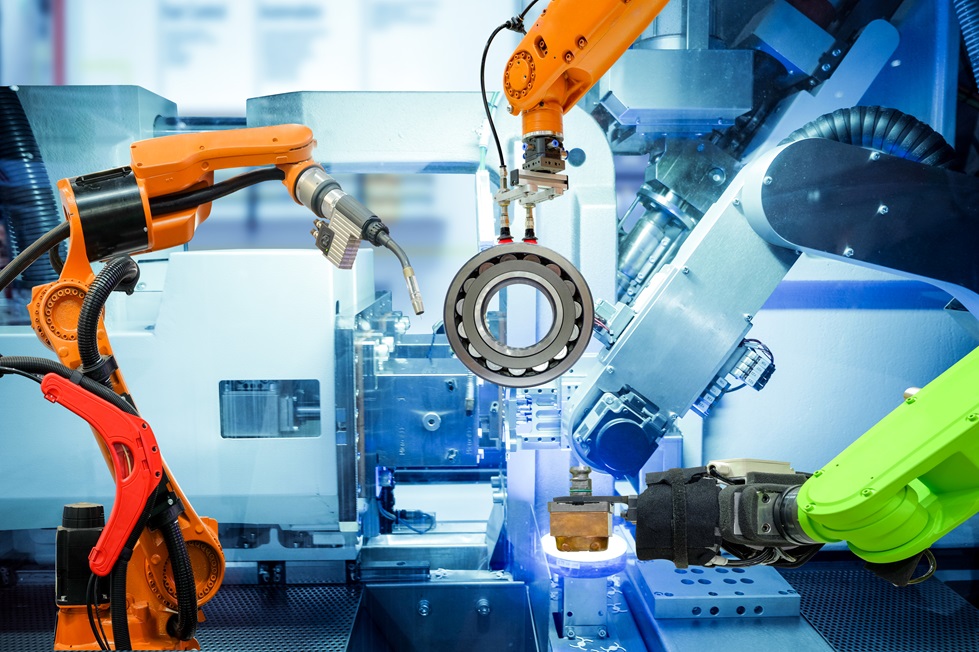

The global robotics industry

According to a 2021 report by the International Federation of Robotics, over 3 million industrial robots are operating in factories around the world, with half a million installations added in 2021, representing an annual growth of 14 percent from 2016 to 2021. Asia was the world’s largest market for industrial robots with 74 percent of all newly deployed robots in 2021 installed in Asia.

around the world, with half a million installations added in 2021, representing an annual growth of 14 percent from 2016 to 2021. Asia was the world’s largest market for industrial robots with 74 percent of all newly deployed robots in 2021 installed in Asia.

One of the major factors driving the growth of industrial robots is the increasing adoption of Industry 4.0, which involves the integration of advanced technologies such as IoT, AI, and machine learning into industrial processes. This has led to the development of more sophisticated and capable industrial robots that can perform a wide range of tasks and interact more naturally with humans.

As per the 2022 McKinsey Global Industrial Robotics Survey, automated systems will account for 25 percent of capital spending over the next five years with the Retail and Consumer Goods industry posed to be the largest spenders. Industrial robots and automation will enable productivity gains, create stable supply chains, and solve skilled labor shortages.

According to the World Robotics Report 2022, the five major markets for industrial robots are China, Japan, the United States, the Republic of Korea, and Germany. These countries accounted for 78 percent of global robot installations. China ranked first in terms of annual installations of industrial robots with 2,68,200 units in 2022 followed by Japan and USA. China now installs more industrial robots per year than the rest of the world put together. The growth in China’s robotization of industries can be attributed to multiple government interventions including the Five-Year Plan for the Robotics industry, released by the Ministry of Industry and Information Technology (MIIT) in Beijing in 2021.

The uptake of robotic automation in these countries is supported by strong Government support, a focus on economic competitiveness and industrial automation, a skilled workforce, a strong industrial base, and significant investment in robotics R&D and innovation.

|

Overall, India’s robotic strategy aims to bring about a paradigm shift in the field of Robotics and enable the country to become a global leader in the research, design, development, and manufacturing of robotics. |

On the future of the Robotics industry worldwide, Dr K Kurien Issac, Former Professor of Mechanical Engg, IIT Bombay and former Professor of Aerospace Engg at IIST Thuruvananthapuram, says, “The Robotics industry is still in a growing phase. The ideal scenario would be when robots are able to do gross and fine manipulations of objects with the ability of human beings and animals, and then surpass them. They also need to be substantially autonomous. The technologies needed to develop such robots have not reached the required levels currently. Machine vision and artificial intelligence are two such areas which need to advance to higher levels. These technologies will definitely reach more advanced levels as there is significant demand for these technologies not only from the Robotics industry but from many other sectors too.”

“Manufacturing and other industries are looking for more autonomous, flexible, intelligent, and accurate robots capable of also working in hazardous environments. The elderly and the handicapped also need robots which can assist them in day to day activities in their homes and outside. There is also going to be a significant demand for robots that can accomplish tasks humans would prefer to stay away from, like clearing sewers, mining, surveillance from the air, deep sea exploration, and defence. Healthcare is another major area for application of robotics where the capabilities of robots have to reach more advanced levels,” Dr Isaac adds.

India’s national robotics mission

Over the past decade, India has made big strides toward strengthening its industrial base with the adoption of advanced manufacturing technologies such as robotics. Since 2016, industrial robots in India have more than doubled to reach 33,220 units in 2021, averaging an annual growth rate of 16 percent. Currently, in terms of annual industrial installations, India ranks 10th globally as per the World Robotics Report, 2022. The long-term potential of robotics in India is enormous and robotics could be a catalyst for revolutionizing industries and driving inclusive growth.

manufacturing technologies such as robotics. Since 2016, industrial robots in India have more than doubled to reach 33,220 units in 2021, averaging an annual growth rate of 16 percent. Currently, in terms of annual industrial installations, India ranks 10th globally as per the World Robotics Report, 2022. The long-term potential of robotics in India is enormous and robotics could be a catalyst for revolutionizing industries and driving inclusive growth.

However, despite its potential, the growth of the robotics ecosystem in India has been slower in comparison to certain developed economies. This can be attributed to several challenges, such as high import dependence, costly hardware components, and insufficient investments in research and development.

Additionally, the paucity of trained personnel for the implementation, integration, and maintenance of robots further hinders the development of the domestic ecosystem. Therefore, to establish India as a global hub for robotics, concerted efforts are required towards mitigation of current ecosystem challenges as well as augmentation of national and state efforts.

India’s Ministry of Electronics and Information Technology (MeitY), serving as the nodal agency for Robotics, have proposed a two-

tier institutional framework to facilitate the implementation of the National Strategy on Robotics. To reap the benefits of deploying robotics at scale, multiple interventions have been recommended across the key pillars of a robotics innovation cycle which include Research and Development, Demonstration and Testing, Commercialization and Supply Chain Development, and Adoption and Awareness.

Dr Isaac says, “The rover of the recent successful Chandrayan moon landing is an example of a space robot. It worked successfully in harsh conditions – moving on sandy and uneven terrain, handling direct radiation from the sun, and working in high temperatures. The basic version of the rover was developed by ISRO more than a decade back.”

“For manned missions, ISRO is in the process of developing humanoid robots that can assist and eventually even replace human beings. As a first phase, a robot which is like a human, torso upwards, and is fixed to a base, is being developed. Non-fixed robots that can float inside the spacecraft in the microgravity environment, and do human like tasks, are also of interest to space agencies,” he adds.

Overall, India’s robotic strategy aims to bring about a paradigm shift in the field of Robotics and enable the country to become a global leader in the research, design, development, and manufacturing of robotics. The Ministry of Electronics & IT (MeitY) is working with various Government organizations and other stakeholders in implementing this strategy and maximising the transformation potential of robotics for India.

|

Reji Varghese MD RV Forms & Gears fngreji@gmail.com |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe