EXPLORING THE TRANSFORMATIVE INDUSTRY LANDSCAPE

A panoramic view of the technological breakthroughs and a thoughtful examination of the challenges and opportunities accompanying them. From Artificial Intelligence and the Internet of Things to advanced robotics and sustainable practices, the following report encapsulates the essence of the transition towards the next technological era.

The ongoing revolution in Industry 4.0 signifies a fundamental transformation in the way industries operate. The revolution revolves around the convergence of the Internet of Things (IoT), data analytics, cyber-physical systems, and Artificial Intelligence (AI). These have been working in harmony to revolutionize productivity, enhance product quality, and nurture agility in manufacturing sectors.

|

The Industry 4.0 wave continues to gather strength in India and across the globe. Digital technologies are likely to constitute about 40 percent of the manufacturing tech spend by 2025 in India. |

The Industry 4.0 wave continues to gather strength in India and across the globe. Digital technologies are likely to constitute about 40 percent of the manufacturing tech spend by 2025 in India. Of which, 50 percent of the digital technology spend will be on Industry 4.0. Further, 50 percent of the spend on Industry 4.0 in India would be on foundational technology, such as Cloud and IoT. Most manufacturing companies across the world are contemplating or implementing a minimum of one metaverse-related use case.

Learning from implementations

More successful use cases are coming up as Industry 4.0 is becoming mainstream. IoT projects have a 14 percent higher success rate today than five years ago. Successful Industry 4.0 projects often share common characteristics, such as strong executive leadership support, a clear strategic vision, effective change management, and a dedicated cross-functional team. In addition, common challenges, such as lack of funding, complex projects, and data management, have reduced by about 50 percent.

Indian manufacturing firms are emulating the global trend of deploying Industry 4.0 solutions, such as connected operations, additive manufacturing, predictive maintenance, and AR/VR. However, about 34 percent of companies are still in the Proof of Concept (PoC) stages in terms of implementing technologies such as AI/ Machine Learning (ML). Thirty percent of Indian manufacturing companies follow a reactive approach when it comes to analyzing data. This is because the data is captured only for a few occasions involving decision-making. In addition, 86 percent of Indian manufacturers have different data management systems with isolated MES, PLM, SCM, and ERP systems. Overall, digital transformation projects across industries have resulted in a more than 25 percent reduction in time taken from PoC to the adoption of RoI.

However, not each Industry 4.0 initiative yields positive results. Challenges are often associated with a lack of alignment between technology adoption and an organization’s goals, inadequate change management strategies, and failure to consider specific contextual factors. Failed initiatives can result in wasted resources, demotivation among employees, and a setback to the organization’s competitiveness.

Need for reference architecture

One of the common problems that manufacturing companies face is siloed systems, resulting in failed Industry 4.0 implementation. This happens as data and insights from systems cannot be used beyond a certain point due to a lack of integration as they cannot connect to other systems, workflows, or other transactional systems. Therefore, organizations are unable to leverage the full potential of Industry 4.0.

|

|

Rather than blind replication of solutions from similar initiatives across industries, companies should come up with reference architecture that will detail the L0 to L5 stack. This would ensure that data flows seamlessly, applications get integrated with each other etc. When an organization implements an Industry 4.0 solution, the reference architecture acts as the guiding framework, thus ensuring that every time a step is taken, it is in line with this reference architecture.

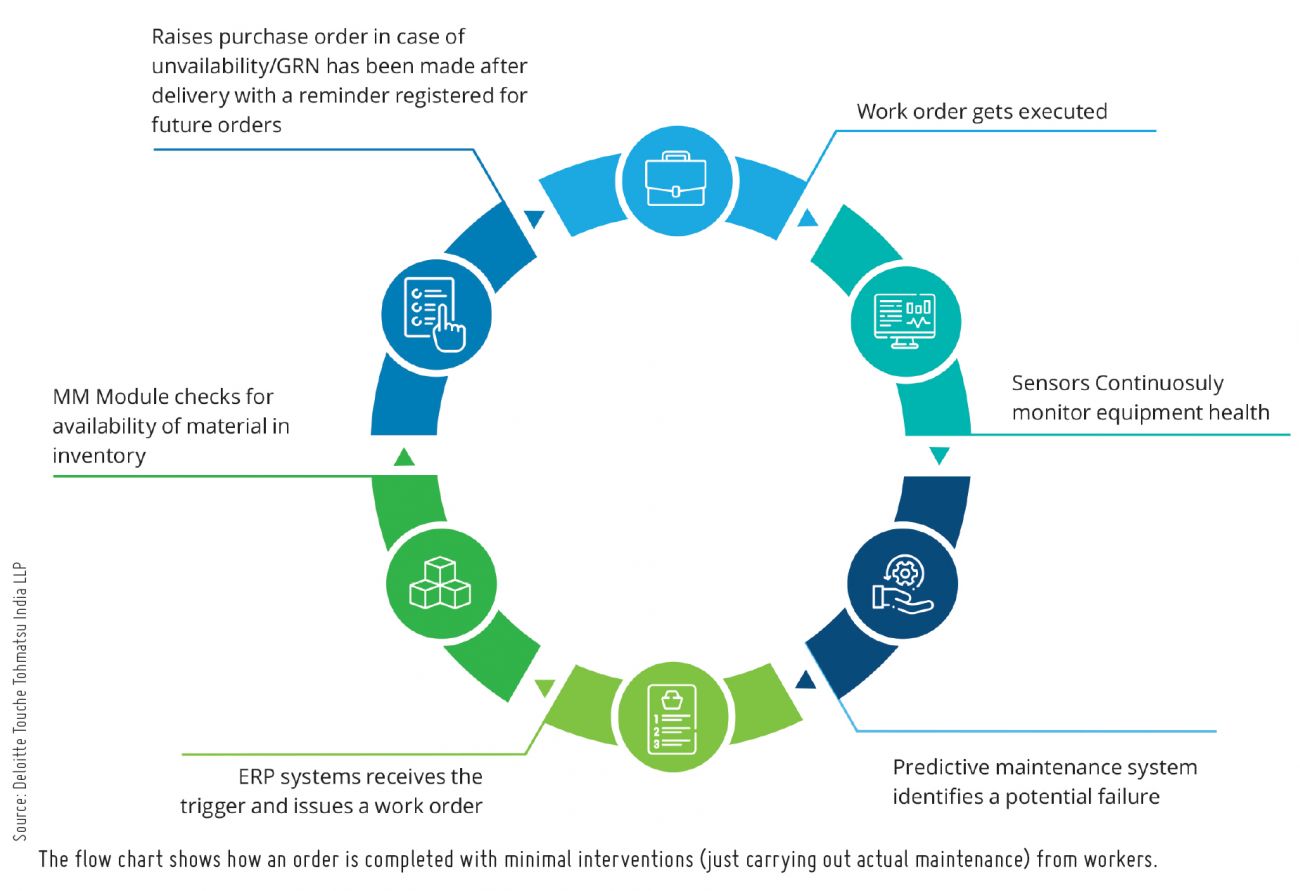

Integrated approach

Integrating systems such as ERP, material management, and analytics tools, helps minimize the time taken to carry out maintenance activities. The below flow chart shows how an order is completed with minimal interventions (just carrying out actual maintenance) from workers.

Leadership acceptance

Organizations should implement a multifaceted strategy that includes conducting leadership workshops and educational sessions to showcase the potential benefits of Industry 4.0. Furthermore, showcasing successful pilot projects and demonstrating their tangible impact on the organization’s bottom line can be a persuasive means of convincing leadership of the initiative’s value. In India, a leading automotive company, under the leadership of its CEO, embarked on a comprehensive Industry 4.0 transformation. It initiated a company-wide narrative for change management, emphasizing the need for digitalization and automation. This commitment from the top-down catalyzed the adoption of Industry 4.0 technologies throughout the organization.

Build vs buy dilemma

Manufacturing companies often find it difficult to decide whether to deploy off-the-shelf Industry 4.0 solution or build a customized one. Their objective is to weigh the benefits of customized solutions with expertise, time taken, and expenses needed for building

from scratch and gains from existing solutions with vendors. Conducting a cost-benefit analysis that considers the advantages of off-the-shelf solutions (such as vendor expertise and shorter deployment times) will lead to a more informed decision-making process.

Success stories from industries

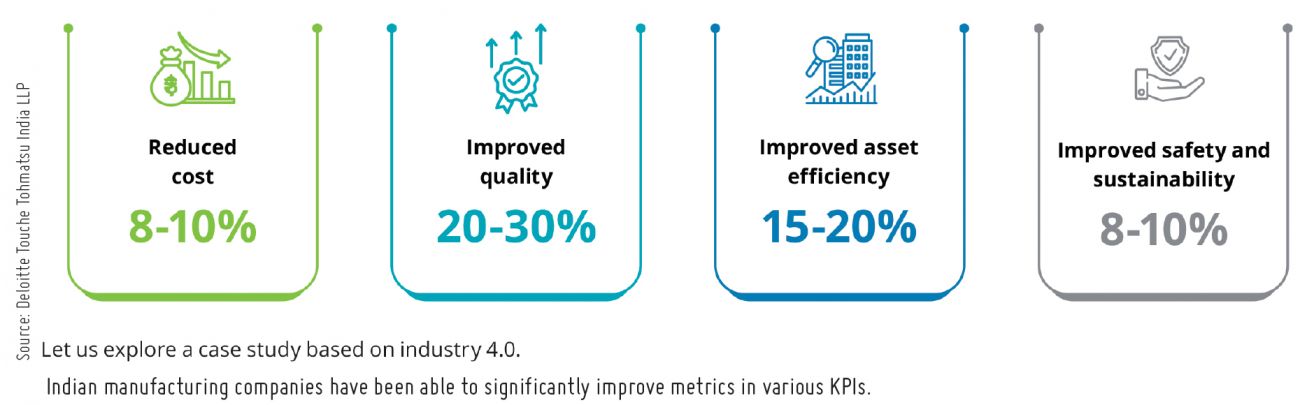

Let us explore a case study based on Industry 4.0.

Low-voltage switchgear manufacturer − brownfield transformation using Industry 4.0

A Mumbai-based low-voltage switchgear manufacturer wanted to transform its plant from three production lines manufacturing variants of switches to a single production line manufacturing more than 200 variants. The challenge was to ensure a balance between productivity improvement and capital infusion. The manufacturer decided to implement an automation and digitalization-based transformation plan.

Goals

The manufacturer started with the following steps:

- Merging three conventional lines into a single production line that is capable of managing more variants and higher production over the combined capacity of the original three lines;

- Ensuring flexibility in production to allow the production of batch sizes that consisted of a single switch;

- Minimizing cycle time;

- Decreasing the time-to-market to 18-20 months from the initial 36 months;

- Meeting higher compliance needs for next-generation products – 68 checks compared with 22 for the older generation.

Methodology

Three technologies – digital twin, a proprietary cloud and IoT system, and video analytics − were used at the core of the transformation.

Digital twin was used to simulate the production process. It virtually replicated design, production, and the end-product. This helped the manufacturer optimize process-based iterations and remove expenditure to produce real-size prototypes, thereby conserving capital while building traceability at subcomponent levels.

Physical assets were connected to the digital ecosystem through a proprietary cloud and IoT system. This helped use data analytics and foster process innovation. The platform helped manufacturers to digitally thread business-side systems, such as ERP with manufacturing execution systems, thus providing greater visibility across the value chain.

Video analytics was used to capture process parameters pertaining to design, make machines smart, and reduce cycle time from 12 to 9 seconds by generating data sets that digital twin had reprocessed.

|

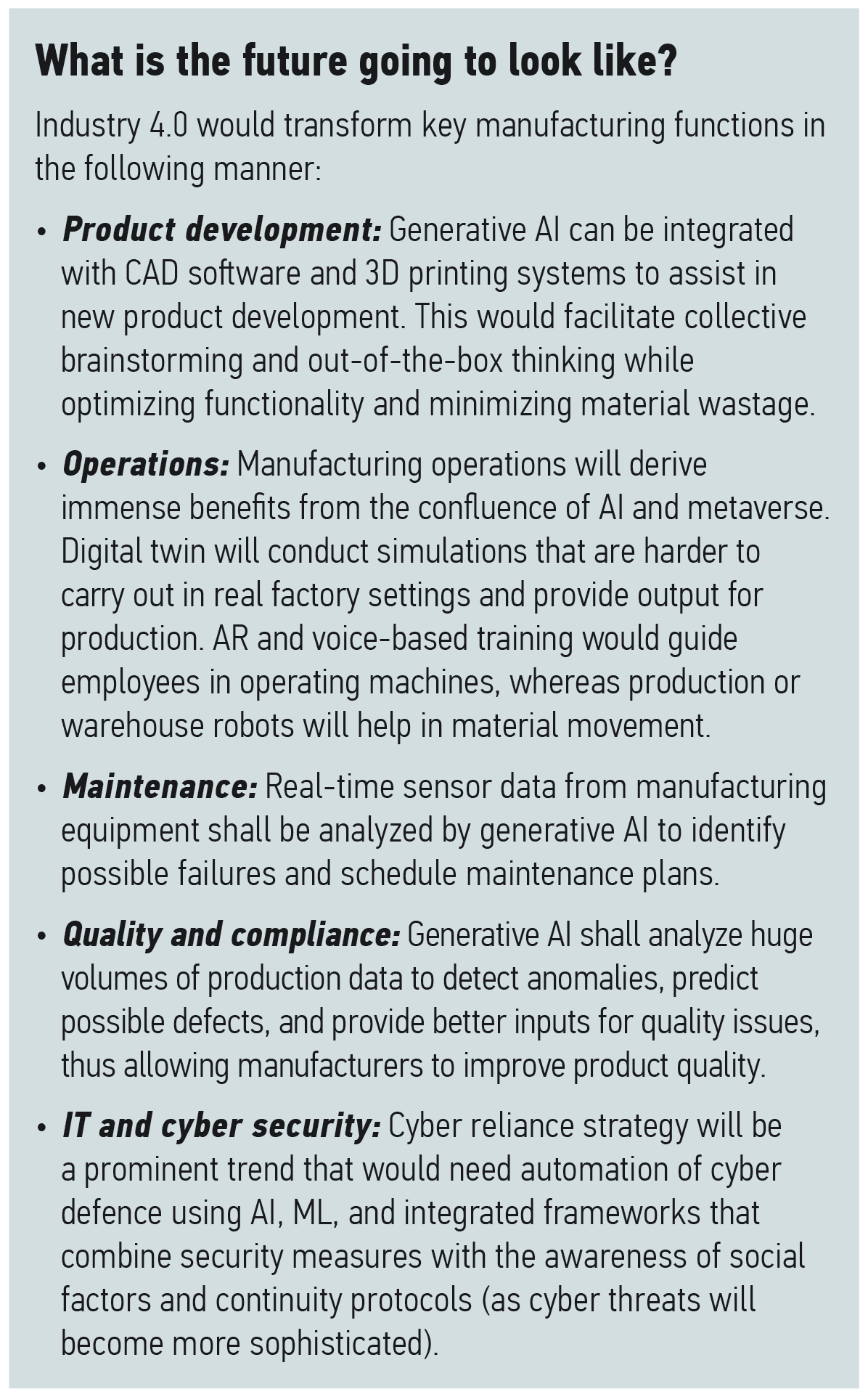

The future of Indian manufacturing is imbued with promise and technological prowess. By adopting a visionary perspective and embracing innovative technologies, Indian companies can spearhead the global Industry 4.0 ecosystem. |

Results

The facility could manufacture more than 200 variants in one manufacturing line compared with 77 variants in three lines. The entire transition process took only 18 months. Overall Equipment Effectiveness (OEE) levels increased compared to the manufacturer’s plant in Germany. Cycle time reduced by more than 50 percent from the original 21 seconds to 9 seconds.

Future forward: 5G, GenAI, and Industry 4.0 powerplay

The ever-evolving technological landscape continues to reshape the Manufacturing industry. Some technologies, such as industrial robots, IoT, and 3D printing, have already stabilized, while others such as digital twin, AR/VR in manufacturing, wearables, and sensors are yet to be fully adopted. Some futuristic technologies are discussed below.

5G connectivity

Given the significant improvement in network characteristics, 5G shall act as a catalyst for digital transformation for enterprises. The new architecture (low latency, high speed, etc.) would make it suitable for time-sensitive applications, such as autonomous vehicles, first responder devices, and smart wearables. Further, the built-in redundancy would enable the network to continuously operate even during emergencies. Private 5G networks would drive innovations in many industrial and enterprise applications and increase reliability, connectivity, scalability, and security compared with previous communication technologies. 5G’s speed and reliability outshine previous communication technologies. It offers continuous connectivity even in demanding industrial environments. It facilitates real-time data exchange which is critical for Industry 4.0 applications.

For example, car manufacturers can employ private 5G networks in their factories to power autonomous transport robots, leading to increased efficiency and safety.

Generative AI

Adapting generative AI would help avoid cost, increase operational efficiencies, and improve worker safety. Companies should also consider legal implications related to copyright infringement and IP ownership of GenAI-generated content prior to implementation. Some use cases include the following:

Increasing worker safety

Issue: Conventional Occupational Health and Safety (OHS) training often focuses on specific situations and does not offer hands-on chances to apply newly acquired skills and information.

Solution: Companies can create tailored and immersive OHS training resources using GenAI and provide trainees safe exposure to authentic scenarios, helping them minimize the occurrence of or improve their responses to real-life OHS incidents.

For example, virtual reality training can replicate operational environment, help employees traverse dangerous situations, identify risks, improve awareness and thereby, respond in a safer manner. Gen AI can help provide customized training materials for select work roles, environments, or regulatory needs.

Furthermore, the content should be designed to be inclusive and accessible to different types of learners including those with disabilities. Companies can also take steps such as adding closed captions and modifying training scenarios in sync with various skill levels.

|

Through digital transformation initiatives, Indian manufacturing companies have been able to significantly improve metrics in various KPIs. |

Providing field assistance to workers

Issue: Shop floor workers often work in challenging or remote environments and usually face challenges due to a lack of information. These challenges include determining the paucity of manuals and identifying the root cause of a problem. This necessitates shop floor workers to reach out to seek additional guidance and arrive back at the site after a period of time.

Solution: A generative AI-enabled field assistant can help engineers provide on-demand access to technical knowledge while supporting them in solving problems, enhancing efficiency, and enabling them to make better decisions.

For example, a generative AI-enabled virtual field assistant can give quick access to a large amount of engineering knowledge and thus serve as a ready reference. Further, the field assistant can help workers by answering questions on fundamental concepts, principles, or calculations. On encountering a challenge in the field, workers can explain the problem to a virtual field assistant. In turn, the assistant can reply with necessary questions to help workers identify the root cause of the problem or provide steps to seek resolution.

|

The convergence of 5G, generative AI, model-based enterprise, and digital thread heralds a new era for manufacturing. AI-driven insights, agile production systems, and real-time data processing will transform industries, enhance adaptability, efficiency, and agility to new levels. |

Companies must ensure that the training data is robust and reliable. Outdated or inaccurate data would lead to incorrect output, resulting in downtime, and compromising the safety of workers and equipment. Further, companies should ensure that skilled workers cross-verify information, especially something that is related to safety, to rule out the possibility of misinterpretation or misinformation.

Companies should train workers to apply their own skills and judgment to avoid overdependency on the virtual assistant as complex situations might require creative problem-solving or critical thinking.

Finally, to avoid complex liability issues in case of incorrect advice leading to accidents or failure in operations, clear guidelines and procedures to address the situations are needed.

|

Companies should be constantly looking out to explore how new technologies, such as 5G, can be used to improve existing systems and prepare themselves for futuristic technologies, such as 6G. |

Model-Based Enterprise and digital thread

The Model-Based Enterprise (MBE) and digital thread are emerging technologies that can serve as the backbone

for manufacturing innovation. MBE lays emphasis on using digital 3D models throughout the product lifecycle − from design and engineering to production and maintenance. MBE and digital thread technologies enhance collaboration, reduce errors, and improve efficiency by enabling seamless data flow across the entire product lifecycle.

A global aircraft manufacturer uses digital thread to streamline aircraft production, reducing costs and improving quality by ensuring that teams have access to the latest design and manufacturing information.

Going forward

The journey of Indian manufacturing companies towards Industry 4.0 has been a testament to their resilience and capacity for growth. Certain technologies such as predictive analytics and 3D printing have already attained a level of stability. Organizations should continue to invest in the latest technologies, such as GenAI, 5G, and digital threads, to remain competitive.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe