EXPLORING MANUFACTURING FEATS

DMTX 2023 (Delhi Machine Tool Expo), scheduled from August 24-27, 2023, at Pragati Maidan, New Delhi, is to feature some of the most cutting-edge technologies from around the world. This preview aims to provide a glimpse of the manufacturing excellence that awaits to be explored at the expo

VISION MEASURING SYSTEMS

For Accurate 2D Measurements

OPTIV LITE OLM is a series of manual Video Measuring Machines from Hexagon Manufacturing Intelligence. Video Measuring Machines, also known as Vision Measuring Systems, are used for quick and accurate 2D measurements of small parts with video edge detection techniques. With the capability to detect edges on high-resolution video through a simple click, the measurement process is expedited and reduces dependency on operators.

|

OPTIV LITE OLM offers several notable features, including:

|

|

|

Asiatic Engineers www.asiaticengineers.com Hall & Stand: 12/A-102 |

METROLOGY STYLI

INDO SERVICES’ STYLI

|

For the past 20 years, Indo Services has been trading replacement styli for all metrology applications used in shop floors, QA labs, standards rooms, and metrology departments throughout India. Post-COVID-19, to cater to the needs of the growing Indian Manufacturing industry, the company’s focus has shifted from importing these replacement styli from Europe to instead manufacturing them in-house as part of the ‘Make in India’ initiative. Its manufacturing range includes styli for critical applications such as Surface Roughness Measurement (with a tip radius of 2 micron and 5 micron), Contour Measurement (with a tip radius of 25 micron), Roundness measurement, and Thread Measurement. Indo Services’ knowledge and experience in the Quality Assurance field aids it in manufacturing special styli as per customer needs. It maintains an exhaustive stock for the benefit of its customers, and most styli are available ex-stock to ensure the best delivery times for them. Its entire range of styli can be accessed on the company website. |

|

Indo Services www.indoservices.net Hall & Stand: 12/A-107 |

DRILL TAP CENTERS

JD 1- HIGH-SPEED DRILL TAP CENTER

|

LMW Machine Tool Division, India’s finest range of CNC Machine manufacturer, presents JD 1, a high-speed drill tap center, that has stroke capabilities of 500 mm on the X-axis, 400 mm on the Y-axis, and 320 mm on the Z-axis. It also boasts a spacious pallet size of 650 mm X 400 mm, allowing for efficient handling of the materials. Equipped with a maximum power of 30 kW, this machine is designed to deliver superior performance and precision. It features a rigid structure that provides a wider working area, allowing for greater flexibility and precision. With a direct drive spindle of BBT 30 and spindle speeds of up to 24,000 rpm, this machine is capable of delivering unparalleled performance and accuracy. The high-speed pocket tilting automatic tool changer ensures smooth and seamless tool changes, while the high rapid transverse rates of 48 m/min enable efficient and speedy movements of the machine. With its advanced features and capabilities, this machine is designed to deliver precision and efficiency in producing components for Automobile, Electric Vehicle, Die & Mold and Electronic industries. |

|

|

Lakshmi Machine Works Ltd www.lmwglobal.com / www.lmwcnc.com Hall & Stand: 11/B-120 |

CNC ROTARY TABLES

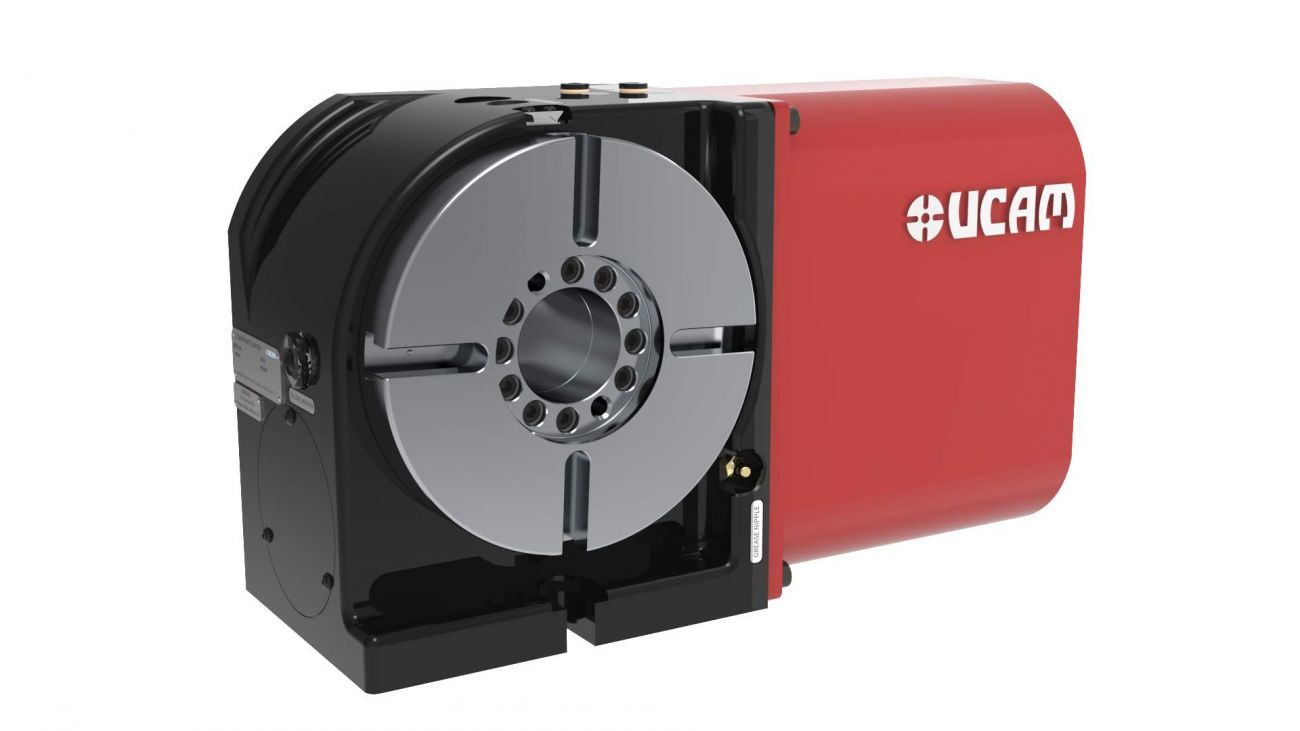

Q SERIES FROM UCAM

|

The Q Series CNC rotary tables from UCAM is designed to revolutionize industries like Automotive, Aerospace, and Medical Device manufacturing. With their compact design and exceptional performance, these rotary tables are poised to enhance production capabilities across various sectors. Features of the Q Series:

|

|

SourcePro Infotech Pvt Ltd Hall & Stand: 12/A-107

ERP SOFTWARE SOLUTIONS SourcePro is an industry leader with the vision of optimizing businesses through advanced ERP software solutions. With more than 25 years of experience in developing enterprise solutions, it provides future-ready business platforms to clients using the latest technology to deliver the best ROI. New Horizon ERP by SourcePro is a smart integrated business solution that allows small- and medium-sized businesses to streamline their critical processes across multiple offices, factories, and locations. Powered by an unmatched MRP engine and auto MIL, New Horizon ERP is a versatile solution for discrete manufacturing that easily adapts to your business and industry needs. This robust platform unifies all business information in 9 core modules to provide a 360-degree view of business drivers and customers at your fingertips. It’s an ideal solution for a broad range of manufacturing houses working on Made-to-Order, Made-to-Stock, and Made-to-Design models. Businesses leverage New Horizon to cope with operational inefficiencies while maintaining their position in the market. As a centralized platform, it helps establish an integrated system for the efficient management of fragmented operations by defining critical processes on the go. It eliminates the transfer delays introduced between processes by smoothening out the internal procedure through enhanced coordination and real-time communication throughout various functions and departments. |

Patankar Industries Hall & Stand: 12A/D-107

Industrial Lamps LED CNC LAMPS FOR VARIED APPLICATIONS For more than 30 years, the brand Patankar Industries has been leading in the field of industrial lamps, offering a complete range of glare-free, highly reliable, long-lasting, and energy-efficient industrial lamps. The LED CNC machine lamp is specifically designed for CNC (Computer Numerical Control) and VMC (Vertical Machining Center) applications. The LED CNC Machine lamp from the company is IP67 water-, oil-, and coolant-proof. The lamp can be rotated 360°. Equipped with Nylon 6 Black mounting brackets, the LED CNC machine lamp is specifically designed to withstand extremely harsh operating conditions. Additionally, it features a diffused polycarbonate lens that ensures glare-free illumination. The new generation of LED lights is specifically engineered to modernize and replace traditional fluorescent industrial tube lights. Premium LED (OSRAM) materials and technology offer 50,000 hours of maintenance-free operation. Available in various lengths, these LED lights are designed as direct replacements for existing light fixtures. With a color temperature of 6500K, they provide clear and bright vision. Moreover, these lights emit no UV or IR radiation, ensuring a safe working environment. They are available in multiple voltage options, including 24 VDC/AC, 10 VAC, and 230 VAC. Additionally, these low-voltage power lamps offer cost-saving energy efficiency. Notably, they are designed to eliminate any stroboscopic effect, providing a stable and consistent lighting experience. LED industrial lamps have a wide range of applications, including: Machine tools applications, Logistics facilities, Cold storage environments, Shop floors, Emergency lighting situations, Forklifts and construction equipment, Paint booth illumination, Marine applications, Vision inspection processes, and EOT crane movement with red or blue lamps. |

WORKHOLDING SOLUTIONS

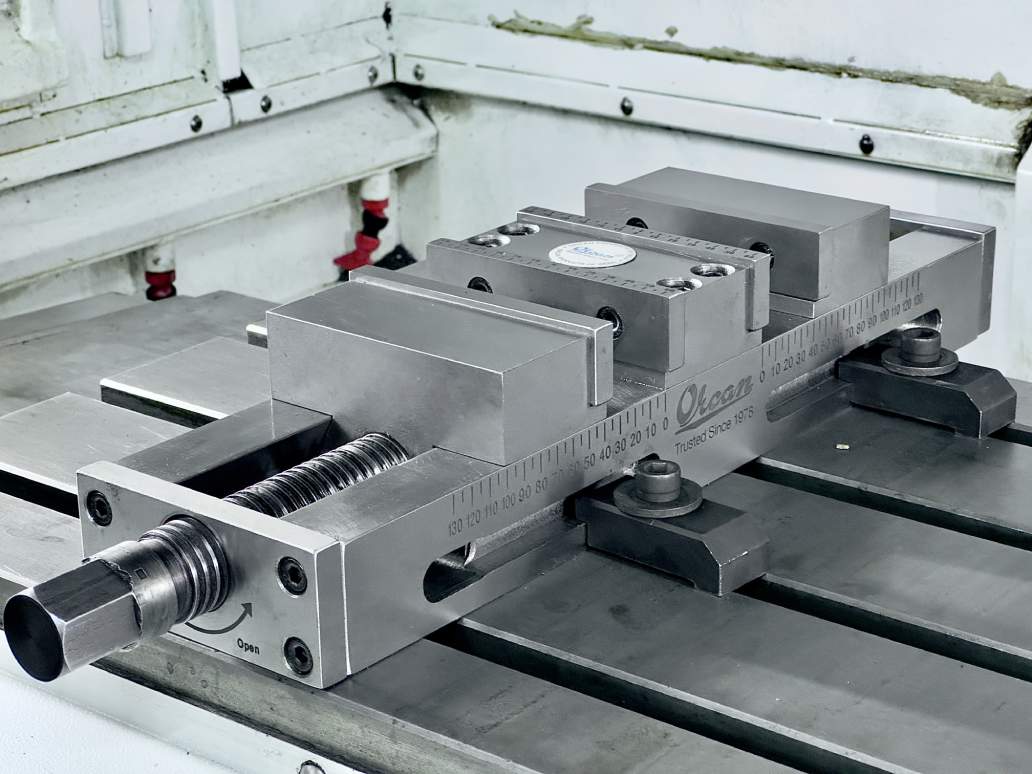

TWIN JOB CNC MACHINE VICE

|

Orcan, the leading workholding manufacturing company with 45 years of experience, has recently launched its latest innovation, the Twin Job CNC Alloy Steel Machine Vice. This new product can hold two pieces of the same size or different sizes, with a jaw width of 125 mm and jaw opening of 125 mm. The Twin Job CNC Alloy Steel Machine Vice has been designed to improve productivity and reduce operator time. By using four vices on a machine table to process eight jobs in one setup, the product can free operator time by as much as 86 percent, leading to increased productivity by up to 7 percent. With an ROI of less than one year, this product is an investment that can pay off quickly. Orcan’s new product is perfect for companies that need to process multiple jobs in a single setup, thereby reducing the downtime between setups. With this product, companies can improve their bottom line and increase their efficiency without having to compromise on quality. |

|

|

orcan products of India www.orcan.com Hall & Stand: 11/C-126 |

VERTICAL TURNING CENTERS

VTC WITH INCREASED CAPACITY

|

Macpower Vertical Turning Center (VTC), the VTX-800, combines power, rigidity, and versatility with increased capacity. Wide access to the chuck zone facilitates ease of loading and unloading of parts. Linear motion guideways on X and Z axes ensure better positioning and repeatability. The major construction parts are based on FG260 grade cast iron to ensure optimum harmonic stability and maximum damping during cutting. The base and the column are reinforced with heavy ribs for stability and minimum distortion. The uniformly dense, fine-graded casting distributes stress and heat throughout the machine structure. A vertical column with higher base contact and an A-type structure strengthens the machine and minimizes the complete overhang for higher travel of the Y-axis. The machine has undergone a thorough inspection process, including Laser calibration, Ball Bar testing, PDI (Pre-Delivery Inspection), and multiple inspection layers to ensure its quality and performance. Macpower VTL machine is ideal for turning heavy, large-diameter components like fly wheels, brake drums, big-size gears, etc. It is conducive for easy loading and unloading of heavy components. It occupies smaller floor space than a horizontal turning machine that can turn comparable-sized parts. |

|

Macpower CNC Machines Ltd www.macpowercnc.com |

|

Mechmatrix Hall & Stand: 11/A-106

CHAMFERING TOOL Often modern CNC shop leaders unknowingly spend more than necessary time and effort in deburring-chamfering operations after machining. Amidst the pressure of increasing productivity and reducing cycle time, the challenge of maintaining a friendly working environment with the operator team adds to the struggle. Mechmatrix provides an innovative solution that substantially reduces operator fatigue and increases productivity in deburring-chamfering operations by 5 times. EASYMECH brand handheld chamfering-deburring tools are proving to be the popular choice to provide world-class edge finishing on machined and pressed components without the operator having to sweat heavily on the shop floor. Modern CNC shops can easily Deburr-Chamfer sharp edges on components after operations including Casting & Forging, Plasma cutting, Laser cutting, CNC machining, Fabrication, Pressed components, Water jet cutting, and Shearing on press brakes. The benefits and savings in the operator’s time and effort provide a substantial reduction in the cycle time. Thus also enhancing respect for the supplier machining the parts. Mechmatrix enables companies to increase profitability by improving productivity. Companies are enabled to become process-dependent instead of person-dependent on the shop floor for secondary edge finishing operations like deburring-chamfering. |

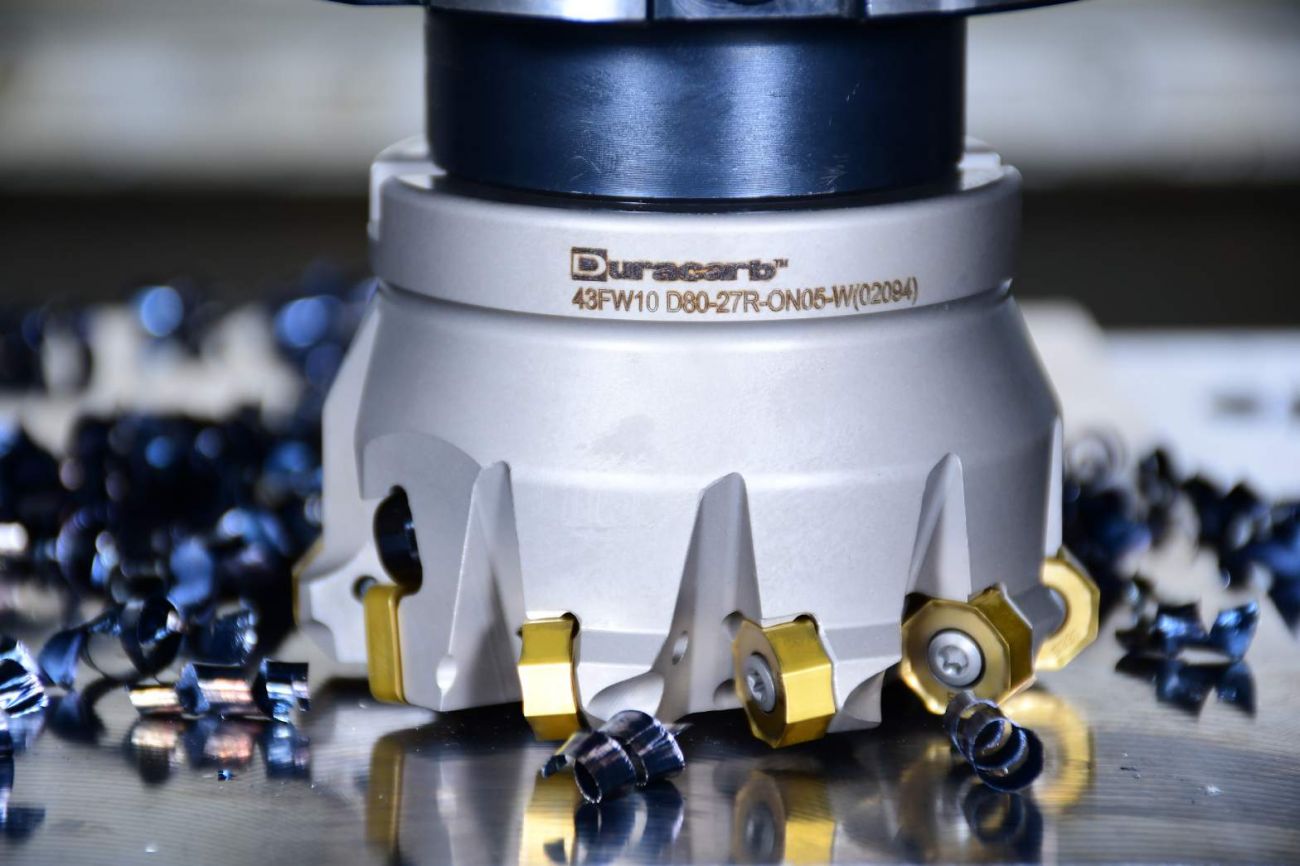

Duracarb India Pvt Ltd Hall & Stand: 11/B-103

INSERTS ONMU 05 & 07 SERIES OF INSERTS High-Feed Milling (HF) is a machining technique that uses a low-entry-angle milling cutter to achieve high metal removal rates in various applications. By using a low entry angle (usually less than 25°), the depth of cut is reduced and the feed rate is increased, resulting in higher productivity and efficiency. Duracarb India provides a wide range of solutions for high-feed milling, from 3-corner to 16-corner inserts, depending on the machining stability. One of the most advanced solutions is the ONMU 05 and 07 series of inserts, which have several features that make them ideal for high-feed milling. These features are:

|

TUBE BENDING MACHINES

ALL-ELECTRIC TUBE BENDERS

Electropneumatics is a market leader in India with the widest range of tube bending machines. One of the latest models the company has introduced is All-Electric Tube Benders, which has bi-directional bending capability. This machine is ideally suited for the bending of complex tubular parts of automobile seating, chair frames in a single setup for the Furniture industry, etc. They are highly productive and produce parts with superior repeatability and quality.

These bi-directional benders have 9 axes with 3 radii bending capability using 3 stacks for different bend radii. The bend head automatically moves to adjust its position vertically for different bending dies and lateral movement for the different radii of the bend.

With the machine, the company also provides tooling and automation for draw bending along with 1D/Boost/Large radius/different material/complex profile benders for special applications.

The machine enables bi-directional bending, allowing for the creation of intricate profiles. All 9 axes of the machine are driven by AC electric servo, ensuring enhanced speed, accuracy, and flexibility. It is equipped with 3 stacks for bending 3 different radii. The optimized parallel axes motions contribute to high productivity. The machine operates cleanly and quietly. Data entry can be done using push-turn-bend (Y-B-C) values or X-Y-Z coordinates. Comprehensive online diagnostics are available for easy troubleshooting.

The machine incorporates Electropneumatics’ Smart Bend CNC system, featuring a powerful and user-friendly

Linux-based touchscreen CNC software with an intuitive interface. It offers programmable closed-loop position-speed control, optimizing parallel axes motions.

|

|

Electropneumatics & Hydraulics (I) Pvt Ltd Hall & Stand: 11/B-109 |

An independent pressure die assist (friction boost) system is included. Anticipatory mandrel withdrawal is implemented for improved efficiency. Automatic self-lubrication is provided for LM guide maintenance. Remote access to the machine is possible using TeamViewer software. Auto diagnosis feature aids in troubleshooting and maintenance. Automatic mandrel lubrication is integrated into the machine’s functionality. Anti-collision simulation software allows for virtual testing on the customer’s PC.

Additionally, an automatic seam detection system is included. Safety measures such as a safety mat, safety flaps on both sides of the bend arm, and an area laser scanner are incorporated. The machine is compatible with Industry 4.0 standards, ensuring connectivity and integration within a smart manufacturing environment.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe