NEW-GENERATION CBN/DIAMOND TOOLS FOR HIGH PRODUCTIVITY

Prof Amitava Ghosh and his research team at IIT Madras are carrying out cutting-edge research on the development of new-generation abrasive tools and advanced grinding technologies. The team is on a mission to develop a wide range of superabrasive tools for versatile applications, which can bring a paradigm shift in a common understanding of grinding.

The tools that the professor and his team are working on are meant to be potentially capable of withstanding a very high material removal rate without compromising the product quality when grinding is practised as a finishing operation by the machining industries of the Manufacturing sector. The research team essentially uses state-of-the-art high-vacuum active brazing technology.

In grinding, an abrasive wheel, which is an aggregate of tiny micro-abrasive particles and bonding material, is used for material removal operations to achieve a high finish and tight tolerances on the part to be produced. Often, they are made of alumina, silicon carbide, cBN (cubic boron nitride), or diamond. These tools are of various shapes. They can be like a small pin, a disc, or of a highly irregular shape too. When high productivity with longer tool life is needed, alumina and silicon carbide are replaced with superabrasives like cBN or diamond. They are superior in their characteristics, hence are called superabrasives. They are superior in terms of hardness and toughness and are highly conductive than conventional abrasives. The product quality and economy of the process largely depend on the performance of such tools.

Knowing multi-point/single-layer tools

|

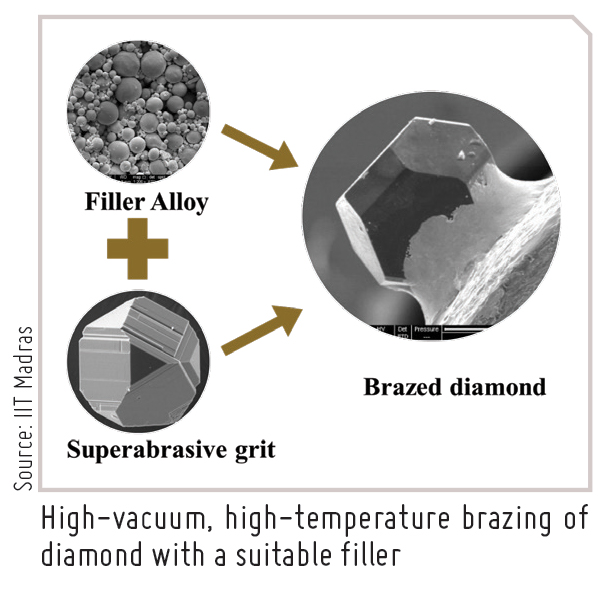

The tools being developed at the laboratory of Prof Ghosh belong to a particular class called multi-point/single-layer tools. Superabrasive particles (grit), made either of cBN or diamond, are brazed on a metallic substrate at multiple points and in a single-layer configuration. The technology essentially requires high-vacuum and super specialty active brazing filler. The active brazing with specialty alloys facilitates extraordinarily good wetting, ensuring higher crystal exposure above the bond level after the brazing of cBN or diamond with steel substrate. It enables an abrasive tool to bite more material during removal if the strength of the joint can withstand high load, thus making active brazing technology a superior choice over its commercial counterpart, electroplating technology. A turbo-propelled high-vacuum, high-temperature brazing furnace that offers a vacuum level of 10-6 mbar at a maximum temperature of 1200° C is used for active brazing. The research group is also developing application-specific novel formulations through extensive research on underlying mechano-metallurgical factors that influence the quality of the tools. These special formulations make the bonding stronger with enhanced wear resistance properties, which, in turn, increase the tools’ life. |

|

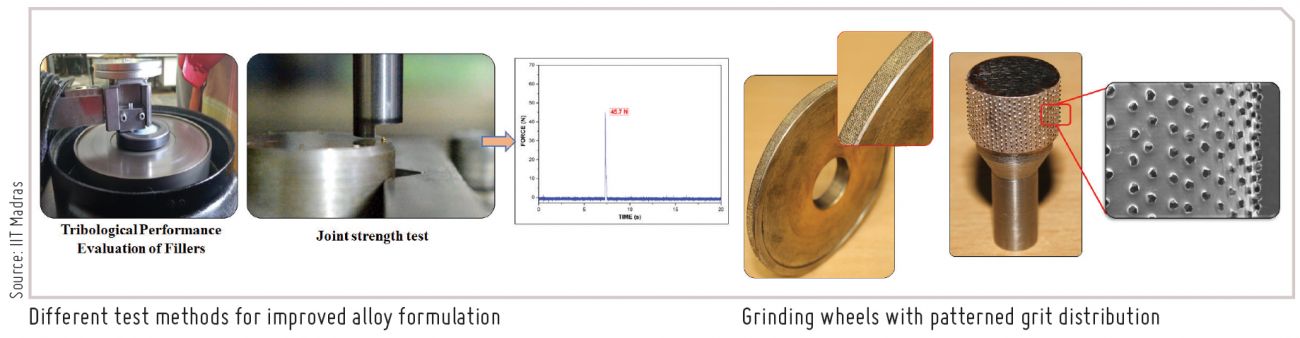

What is more novel to the approach of making these new-generation grinding tools is positioning the grits uniformly on the working surface in a custom-designed manner. This design of the pattern is exclusively application driven. As Prof Ghosh explains, “This uniform grit distribution pattern will be extremely effective in terms of realizing grinding with high material removal rate without traces of wheel loading as it can accommodate a larger volume of chips in the inter-grit space. The arrangement does not compromise on achieving an adequate level of precision on the part being ground.”

New-gen tools superior to commercial counterparts

The newly developed tools have been rigorously tested in the lab for their capability and superiority to the available commercial products. The research team has developed, in-house, a novel test bench to experimentally quantify the force-withstanding capability of the joint and a high-speed grinding test rig to evaluate the performance of the tools and compare the same with that of commercial counterparts against various workpiece materials. Such a diamond tool with a 120 mm diameter was found to be capable of abrasive-milling of an aluminum composite with a depth of 2.5 mm without any loading and bond breakage, even when used in a vertical machining center. In summary, these new-generation single-layer tools are potentially far superior to the commercial ones in terms of stronger joint strength, higher crystal exposure, higher tool life, and patterned grit distribution.

Machining and grinding tool manufacturers are the direct potential beneficiary of this technology. The tools can be produced for versatile applications found in Aerospace, Automobile, Mining, and Medical sectors, such as rock cutting, ceramic grinding, deep grinding of profiles on metallic alloys and composites, precision dressing, and surgical dentistry procedures.

The work has been showcased at IIT R&D Fair 2022 at IIT Delhi and very recently at the i2-Academia Pavilion of IMTEX 2023 held at Bangalore International Exhibition Centre. It received recognition and appreciation from pioneering industries in the relevant field. The team is keen to upscale the technology and looks forward to transferring it to a competent hand to contribute to the ‘Make-In-India’ initiative. “The untiring efforts of the group’s research scholars including Prithviraj Mukhopadhyay, Raghava Simhan D, and Trilochan P Nanda have paved the path of the journey. I also acknowledge the financial support from SERB, the Indian Government, and IIT Madras for accomplishing the R&D activities,” adds Prof Ghosh.

|

The tools can be produced for versatile applications found in Aerospace, Automobile, Mining, and Medical sectors, such as rock cutting, ceramic grinding, deep grinding of profiles on metallic alloys and composites, precision dressing, and surgical dentistry procedures. |

|

Dr Amitava Ghosh Professor in Mechanical Engineering Department IIT Madras amitava_g@iitm.ac.in |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe