MEETING MARKET NEEDS

Mekhos Technology Services, an SME that provides assembly and testing solutions to customers for their industrialization needs, successfully met its client’s specific needs, leading to improved productivity, reduced manpower, and increased savings.

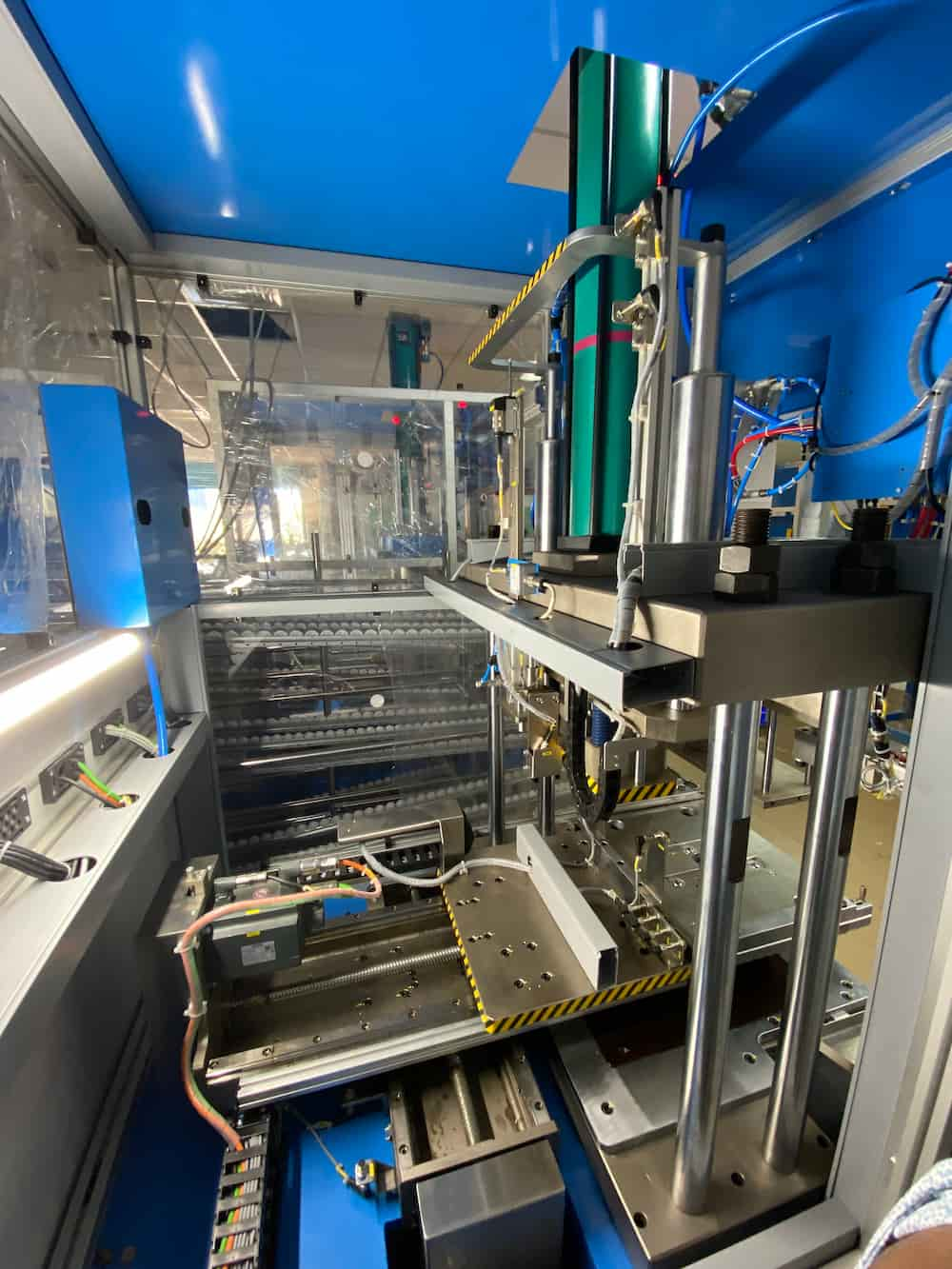

Mekhos Technology Services Pvt Ltd supplies automatic assembly lines, assembly machine technology, and automatic testing machines across a range of industries. Its solutions are custom designed to suit the product quality and productivity requirements of the customer. Founded in 2015, the company today is run by 140 tech enthusiasts whose innovative spirit has made it the National Productivity Championship Winner at the recently held Indian Machine Tool Manufacturers’ Association’s National Productivity Summit in Bangalore.

The following case study is what made it the winner. In this particular case, the customer was a manufacturer of Cabin Latch units for different OEMs at global locations. They produce multiple variants of these latches. The core function of the product remains the same, but the variants are different in terms of dimensional variances and child parts.

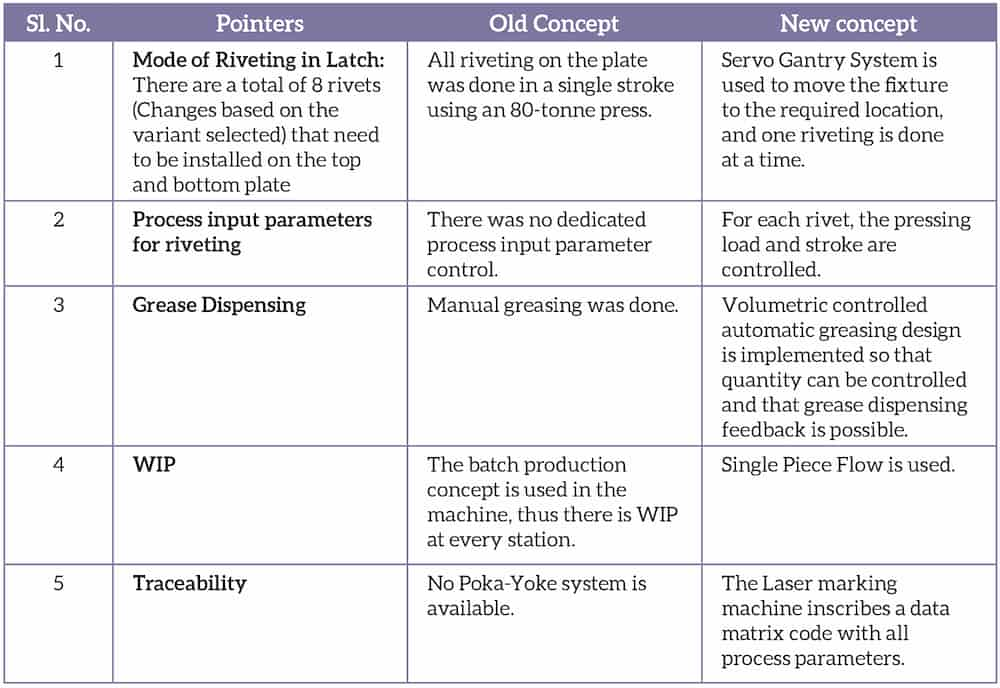

The requirement floated to Mekhos included an assembly and testing solution for the latch that must meet quality and productivity specifications. The objective was to create an assembly and testing line that would use only eight operators to assemble the latch unit, instead of the 28 that were being used. The existing line had its share of limitations, including the inability to handle newer variants within the existing machines, a high rejection rate, missing Poka-Yoke, and the inability to collect and process data. Each variant had a different set of child parts, assembly parameters, and operations. The mammoth task was to design a single assembly line that could take care of the assembly of all the variants, since having a separate machine for each variant was not a feasible option.

Three main assembly lines for the latch and one offline assembly line for the hydraulic cylinder were running at a cycle time of 72 sec/line three shifts in a day to produce the required output at an estimated OEE of 85 percent. Some of the problems faced included high rejection rates because of the lack of Poka-Yoke and process control, which increased the per-piece cost of the output. Running the line in three shifts was expensive because of the extra wages paid to the night shift workers and other overheads involved. The changeover time from variant to variant was high, around 30 min, which significantly impacted productivity. Another main problem with the existing line was that the end-of-line testing machine was not capable of testing all the variants. Hence, the end-of-line testing consisted of separate machines, each to test one particular variant.

With these and other problems at hand, the new line had to be designed with decreased manpower which would run in only two shifts. It had to have all the required Poka-Yoke and end-of-line checks to reduce the rejections. The riveting process needed to be a closed-loop system to ensure better process control, and the changeover time needed to be less than 5 min.

Trying out solutions

Multiple solutions were tried; process failure mode analysis, cycle time analysis, risk analysis, and man-machine movement analysis were performed. Based on the data, a final solution was accepted. The company started with process mapping. Process mapping for each variant was performed to study how a common process could be developed across all variants. Each variant was analyzed individually for the process-specific details and the child parts involved in it, marking the important process parameters to be achieved. Upon analysis of each variant, the data was assimilated, and all the processes across all variants were mapped. The distinguishing elements in each variant and the points of similarity were drawn to analyze how a smooth flow of man and material across variants can be achieved. Based on this study, the single-piece flow concept was stabilized by balancing the line for each model, which is used for the detailed cycle time study across all variants. This study also highlighted the difference in the process for each variant, which was further used during design to stabilize relevant Poka-Yoke in the line-specific variants.

Based on the identified failure mode from the PFMEA of the customer, Poka-Yoke was stabilized in the line. Different layouts were tried, and analysis using the software was done to arrive at the most optimum layout. The automatic part of the machine was simulated using software and mathematical calculations to arrive at the cycle time of each section, along with software analysis, a physical model of the machines was developed, and manual time was simulated to confirm the presented cycle time of each variant.

An extensive cycle time study was performed for each activity for each variant per station. A man-machine diagram was plotted across variants. Based on the output generated, the productivity plan for the full line was generated. With the above analysis, the cycle time for each variant was generated against the requirement. Along with the mathematical calculations, a physical model of the machine was generated and manual time simulation was carried out to support the study.

The complete product and quality requirements were extensively studied, and based on that, a concept was developed for the production line. Some major innovative concepts, with a comparison with the old production line, are drawn out below.

Achieving goals

The machine was designed and made in India and shipped to the Netherlands in Europe. With improved machine process capability and overall equipment efficiency, the total output was drastically increased. This meant what once took three shifts to manufacture, took only two. This had a direct impact on energy consumption and carbon footprint. Further, since the process was optimized using automation, consumable waste was also significantly reduced. The main idea behind this program was to improve the bottom line with the given revenue. Direct manpower in the production line was reduced by 71.4 percent, which resulted in a direct saving of `12.8 crore. The rejection rate in the line was improved, resulting in a direct saving of `1.275 crore annually. Direct material consumption in the line was reduced in terms of grease, which resulted in a saving of `0.6370 crore. Tool life increased by fivefold, reducing the running cost of the line.

The client was able to generate substantial savings through the implementation of the assembly line and recover the investment made on the project in just eight months.

With improved machine process capability and overall equipment efficiency, the total output was drastically increased. This meant what once took three shifts to manufacture, took only two. This had a direct impact on energy consumption and carbon footprint.

The main idea behind this program was to improve the bottom line with the given revenue. Direct manpower in the production line was reduced by 71.4 percent, which resulted in a direct saving of `12.8 crore.

Poonam Pednekar

Chief Copy Editor

Magic Wand Media Inc

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe