CREATING NEW AVENUES

In this exclusive interview with Soumi Mitra, Editor-in-Chief, MMI, Dr John W Mitchell, President & CEO, IPC, talks about the association and its support to the Indian electronics manufacturing industry, how he views our industry’s growth, IPC India’s 10-year celebration, supply chain challenges, and ways to turn them into opportunities.

Kindly tell us about IPC’s role as the voice of the global PCB industry.

Dr John W Mitchell: IPC is the global not-for-profit trade association that helps OEMs, EMS, PCB manufacturers, cable and wire harness manufacturers, advanced packaging companies, and Electronics industry suppliers build better electronics. IPC members strengthen their bottom line and build more reliable products through proven standards, certification, education and training, thought leadership, advocacy, innovative solutions, and industry intelligence. IPC represents all facets of the Electronics Manufacturing industry, including design, advanced packaging, printed board manufacturing, electronics assembly, and testing in over 70 countries, including India. How do IPC’s regional offices in Bengaluru and New Delhi help OEMs, Electronics Manufacturing Services (EMS) companies, PCB manufacturers, cable wire harness manufacturers, and electronics industry suppliers in India build 2010 electronics better through skill training and certification?

How do IPC’s regional offices in Bengaluru and New Delhi help OEMs, Electronics Manufacturing Services (EMS) companies, PCB manufacturers, cable wire harness manufacturers, and electronics industry suppliers in India build 2010 electronics better through skill training and certification?

Dr Mitchell: IPC was incorporated in India in 2010. In the past decade, IPC has supported the Indian Electronics Manufacturing industry through global standards, certification, education, and skills training. IPC’s India office has certified over 11,000 professionals in the industry and has helped companies enhance their product quality and reliability. Numerous Indian SMEs, exporters, and PSUs are actively engaged in and utilize IPC products, services, and resources. IPC’s members serve various vertical industries like Defense, Automotive, Healthcare, Aerospace, Telecom, ICT, Power, Railways, and Broadcasting. During the COVID-19 pandemic, when member companies were facing challenges in visiting our skills training center at Bengaluru, we launched virtual training for some of the certification programs, such as IPC-A-610 Acceptability of Electronics Assemblies. IPC India has a pool of instructors based out of Bengaluru, Chennai, Hyderabad, New Delhi, and Pune, and this has helped members engage with IPC resources.

How, according to you, is electronics manufacturing growth in India?

Dr Mitchell: We are excited about current manufacturing opportunities in India. The Indian Electronics industry is forecasted to grow to US$300 billion by 2026 from its current level of US$75 billion. India is poised to become a global manufacturing hub, exporting approximately US$120 billion by 2026. This market size explosion has been catalyzed by the COVID-19-led growth of digital consumption. Electronics manufacturers are also seeking diversification of global value chains, and it makes sense for India to be a focus area. The Government’s ‘Policy on Electronics’ provides a roadmap to position India as a global hub of Electronics System Design & Manufacturing (ESDM) by encouraging and driving capabilities in the country for core component development, including chipsets, enabling an environment for the industry to compete globally. Production Linked Incentive (PLI) scheme will help boost large-scale domestic manufacturing. Electronics manufacturing clusters will enable a world-class electronics infrastructure. Electronics manufacturing has been growing quite significantly in India, and IPC would like to support the Government of India by providing resources that will help electronics manufacturers create better quality products, facilitated in part by a better-trained workforce.

Electronics manufacturing has been growing quite significantly in India, and IPC would like to support the Government of India by providing resources that will help electronics manufacturers create better-quality products, facilitated in part by a better-trained workforce.

As part of IPC India’s 10-year celebration, a series of activities, including member networking events and skills challenge competitions throughout India, culminated in the inaugural Integrated Electronics Manufacturing & Interconnections (IEMI) events in Bengaluru and New Delhi. What were the two events focused on?

As part of IPC India’s 10-year celebration, a series of activities, including member networking events and skills challenge competitions throughout India, culminated in the inaugural Integrated Electronics Manufacturing & Interconnections (IEMI) events in Bengaluru and New Delhi. What were the two events focused on?

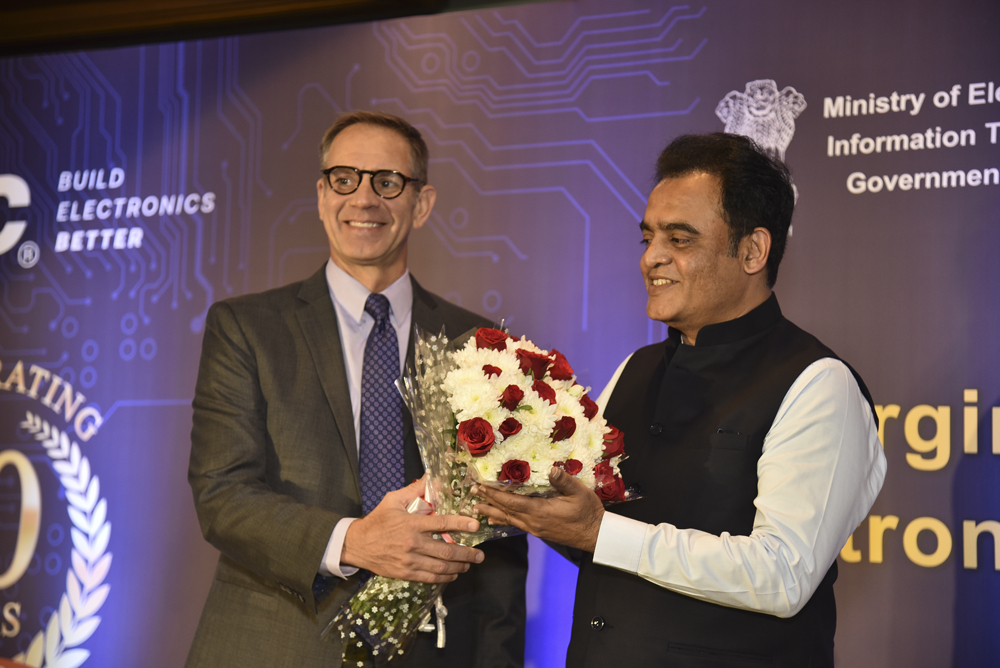

Dr Mitchell: As part of our 10-year celebration, IPC India organized the inaugural Integrated Electronics Manufacturing & Interconnections (IEMI) event in New Delhi on August 2 and Bengaluru on August 4. The event in New Delhi focused on ‘Emerging Tech, Industry 4.0 & Mobile Manufacturing’ and the event in Bengaluru was dedicated to ‘India – Emerging Aerospace Electronics Hub’.

India has emerged as the second-largest manufacturer of mobile handsets in the world in terms of volume, and we wanted to focus our IEMI events on emerging technologies and Industry 4.0. In New Delhi, we covered the Electronics sector opportunities in reference to the Government investment schemes that have led to the success of mobile manufacturing.

There are several Government and industry initiatives, and new R&D facilities and startups being established, driving innovation in new aerospace electronics technologies being developed in India. This has resulted in India rapidly expanding its global presence as an Aerospace industry hub. The city of Bengaluru is taking the lead in aerospace growth, and we felt it was important to discuss these opportunities with IEMI delegates.

One of the major attractions of IEMI was skill challenge competitions on hand soldering, wire harness, and PCB design. How many companies and professionals participated, and how were the winners acknowledged?

One of the major attractions of IEMI was skill challenge competitions on hand soldering, wire harness, and PCB design. How many companies and professionals participated, and how were the winners acknowledged?

Dr Mitchell: For the first time, IPC India took hand soldering, wire harness, and PCB design skills challenge competitions directly to member companies so that the maximum number of employees could participate. More than 100 companies and over 1,500 employees were involved in the first round of competitions at different company locations in India from January through April this year. The three best competitors were chosen by each company for the semi-final round. Under the guidelines of expert judges, the events were observed either virtually or in person. IPC standards were followed in preparing the schematics for the competitions. From May to July, semifinal rounds took place at different locations in India and nearby countries, including Sri Lanka (Colombo) and the United Arab Emirates (Dubai), featuring winners from preliminary rounds. With support from other Electronics industry Associations (MCCIA, TELMA, ELCIA, SICCI, GEZIA, and ELCINA), IPC India successfully organized these events throughout India. The final round of the skills challenge competitions took place at the IEMI event in Bengaluru. Winners and runners-up participated in each semi-final round. At the awards presentation, winners and runners-up received a trophy, a certificate, and, in some cases, cash prizes. The winners and runners-up of the hand soldering competition will participate at the IPC World Hand Soldering Championship in Munich, Germany, on November 16-17, 2022, during electronica. Please share your thoughts on how supply chain challenges for the EMS industry can be addressed.

Please share your thoughts on how supply chain challenges for the EMS industry can be addressed.

Dr Mitchell: Today, the EMS industry is hit with component and raw material source shortages, particularly for bare PCB boards. Trade wars with certain countries have brought these challenges to the forefront. The COVID-19 pandemic has also created a unique growth opportunity for India. Supply chain disruptions during the pandemic forced many countries and organizations to re-think their sourcing strategies and reduce dependency on one country for their supplies. The policy of ‘Make in India’ and the large OEMs’ looking to ‘buy from India’ has helped the EMS industry’s growth and solved supply chain issues.

The Indian ESDM industry is focusing on PCB manufacturing within India, and large companies are looking at investment opportunities within the country. Supply chains should not be planned and managed with a single-dimensional focus on costs. The best supply chains are agile, adaptable to market changes and customer needs, and aligned with a company’s interests.

What are the other challenges the industry faces, and is there a way to turn them into opportunities?

Dr Mitchell: What we are experiencing today is the new normal. Innovation at all levels, including product, technology, and business, giving rise to newer businesses that are challenging the incumbents. As there could be a re-alignment of global supply chains in the coming years, India is likely to benefit immensely from these strategic decisions and become a manufacturing powerhouse. A favorable business environment, liberal foreign direct investment norms, constantly improving ‘ease of doing business’ rankings, an enormous consumer base, and a rapidly improving digital infrastructure are some of the key factors that will drive investment in India in the coming years. A digital supply chain is one of the areas of focus for Indian companies. The other challenge the industry faces is a dearth of skilled workforce and its retention. IPC is working with the industry to solve this by providing education, skills training, and certification. In 2021, IPC certified more than 1,00,000 electronics manufacturing workers globally. IPC India will be starting a new initiative for training students in their final year of engineering studies and students receiving diplomas in electronics assembly, making them ready for the industry. The first project will start in Mysore and will be replicated in other parts of India.

The other challenge the industry faces is a dearth of skilled workforce and its retention. IPC is working with the industry to solve this by providing education, skills training, and certification. In 2021, IPC certified more than 1,00,000 electronics manufacturing workers globally. IPC India will be starting a new initiative for training students in their final year of engineering studies and students receiving diplomas in electronics assembly, making them ready for the industry. The first project will start in Mysore and will be replicated in other parts of India.

It is important for the Government and industry to work together to create a ‘roadmap’ for new opportunities. IPC, in addition to training and certification opportunities, provides platforms and events such as IEMI for business networking and strategic partnership exploration.

IPC India is associated with the Government of India’s important missions like ‘Make in India,’ ‘Digital India,’ and ‘Skill India.’ Please elaborate on the same.

Dr Mitchell: In 2010, IPC established its India headquarters office in Bengaluru. From 2010 to 2021, IPC provided over 11,000 certifications for professionals involved in electronics manufacturing in India. Several Indian small and medium enterprises, exporters, and public sector units are actively engaged in IPC training and certification. We have noticed that a sizeable number of startups are sending their employees for IPC certification to help prepare them to work effectively with Indian OEMs. In the last few years, two of IPC’s certification programs have been very popular: IPC-A-610 Acceptability of Electronics Assemblies and IPC Designer Certification. The Design and Manufacturing sector in India is predicted to reach US$220 billion by 2025. IPC plans to support the Government of India by providing resources that will help electronics manufacturers create better-quality products and enhance job skills.

IPC members are said to be excited about the printed circuit board assembly (PCBA) opportunities in India. How does India interest major manufacturers in the industry?

Dr Mitchell: PCB assembly is a critical piece of electronics manufacturing. PCBs are at the core of every electronic device. India’s electronics manufacturing production is led by mobile phones, IT hardware (laptops, tablets), consumer electronics (TV and audio), industrial electronics, automotive electronics, electronic components, LED lighting, strategic electronics, wearables, hearables, and telecom equipment. It is important for the Government and industry to work together to create a ‘roadmap’ for new opportunities. IPC, in addition to training and certification opportunities, provides platforms and events such as IEMI for business networking and strategic partnership exploration. IPC India members have been invited through a special Government of India program to exhibit at the ‘India Pavilion’ at IPC APEX EXPO in San Diego, California, USA, on January 24-26, 2023. IPC APEX EXPO provides a great platform for IPC members in India to create new business opportunities.

IPC plans to support the Government of India by providing resources that will help electronics manufacturers create better-quality products and enhance job skills.

SOUMI MITRA

Editor-in-Chief

Modern Manufacturing India

soumi.mitra@magicwandmedia.in

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe