Changing Medical Implants

Additive manufacturing provides new ways of making medical implants, but its impact is greater than this.

Additive manufacturing (AM) has been used to make medical implants for more than a decade now. 3D printing technology has allowed implant manufacturers to create complex geometries that copy the shape and function of natural bone and to produce these items on an accelerated timeline.

But additive manufacturing’s role in the medical field continues to develop and mature. In a recent issue of Additive Manufacturing magazine, we highlighted a number of 3D printed implant applications, ranging from devices used in successful, completed surgeries to research that will influence the next generation of medical devices. Our reporting shows that 3D printing is not just an alternative method for manufacturing hip cups and spine cages at scale; it is actually reshaping what implants can do and how patients can be treated.

Many reconstructive procedures still require a fair amount of handwork and artistry on the part of the surgeon. But working with a bespoke implant made for the patient at hand means that the surgeon has less adjustment and manual work to do in the operating room.

Here are four ways that 3D printing is changing medical implants:

Accelerating product development. 3D printing allows for the creation of new kinds of geometries, such as trabecular lattices to encourage bone in-growth on a given implant. The technology offers not only the capability to create and test these geometries, but to prototype them using the intended manufacturing process and to do so quickly. When the right design is found, the implant can go into production right away. As Ryan Hanes, VP of business development at implant maker Amplify Additive says, with additive, ‘the prototype is the product’.

Making custom implants more accessible. Rapid product development leads to another advantage with 3D printing technology: Custom implants can likewise be developed and made much more quickly. Patients can have access to implants made to fit their bodies, resulting in easier surgeries and better health outcomes. Surgeons at the University of Miami recently created a 3D printed titanium talus bone for a patient with sickle cell disease, for example. Rather than fusing the patient’s ankle to the hindfoot, a procedure that would have taken away her ability to move the foot, this replacement talus was able to preserve that mobility.

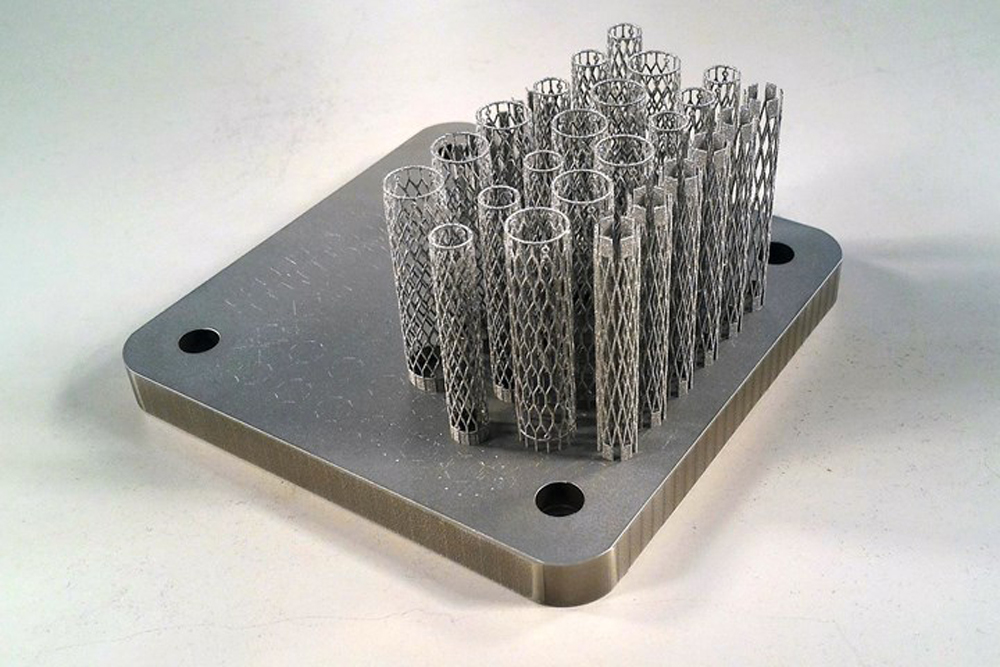

The ability to 3D print with nitinol will allow stents like these to be made in greater varieties to suit more patients.

Creating new opportunities with biocompatible materials. 3D printing technology offers new ways of working with common implant materials. Researchers in Australia have proven a process for the 3D printing of stents made from nitinol, a shape memory alloy that will resume its intended geometry after deformation; the material is already used for arterial stents, but the ability to apply it with 3D printing could enable more sizes and configurations to make easily. Polymers and other materials can benefit from additive manufacturing as well; bioceramics used as support structures and artificial bone graft can be 3D printed into precise geometries to fit a patient’s anatomy, for example, rather than having to be packed manually by the surgeon.

This glaucoma stent is about 1 mm long, and was built using microscale 3D printing by Boston Micro Fabrication (BMF).

Simplifying procedures. The ability to create custom implants for specific patients has added benefits during the course of treatment. Many reconstructive procedures still require a fair amount of handwork and artistry on the part of the surgeon. But working with a bespoke implant made for the patient at hand means that the surgeon has less adjustment and manual work to do in the operating room. Procedures can be accomplished faster and less invasively; patients, therefore, recover more quickly and have better health outcomes. 3D printed implants could even reduce the number of surgeries necessary for a given condition. For example, glaucoma stents 3D printed from a dissolvable polymer could eliminate the follow-up surgery necessary to remove the titanium devices commonly used today.

Stephanie Hendrixson

Contributing Editor

Modern Machine Shop

shendrixson@mmsonline.com

Source: Modern Machine Shop

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe