Why Entrepreneurs Must Keep Learning?

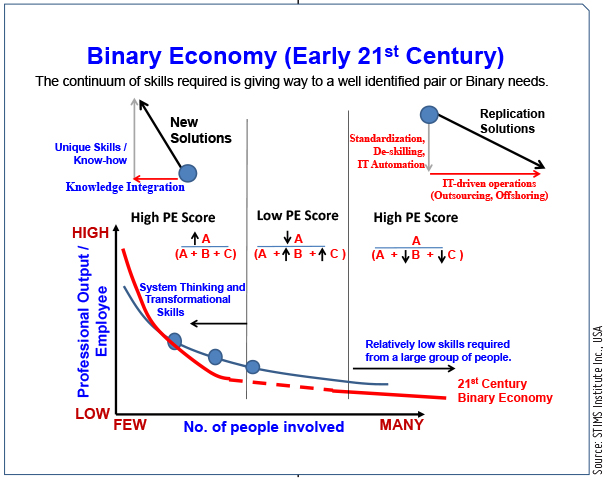

Professionals, including the ones in manufacturing, use their knowledge to solve problems or develop and implement new solutions. Increasingly they feel that they can leave their knowledge at home as they are asked to follow rules or standard operating procedures (SOP). These rules and practices are based on standardization of the tasks already known. These “replication solutions” based on IT tools and applications leave little room to think. The solutions also require lower or no skills at all.

Who exactly are ‘intrepreneurs’?

At the same time, we hear a constant drum beat for professionals to be entrepreneurial, capable of handling a variety of jobs and problems. This is in total contrast to the standardized and de-skilled task-oriented replication activities. There are many opportunities to integrate knowledge from various sources – from other workers, knowledge available across departments, with the suppliers as well as with the customers or end-users. The advent of smart phones, Facebook, Google and other search engines also augment this ability to aggregate information from across the globe and convert them into new knowledge. The result is a “new solution” of high added value. They are heralded as “entrepreneurial”. The new term used for such entrepreneur working inside a company – as opposed to a startup operation – is “intrepreneur”.

These two modes of working – replication solutions vs. new solutions – are creating a pull in the opposite directions. The net result is a rupture in the middle. In other words, there is no demand or value for those who operate in the middle level of skills or capabilities. Whether you fall in the low wage and low skill category or lost in the “middle” or in the high wage, high demand new solution providers can be judged by your PE Score.

What is your Professional Efficiency (PE Score)?

The work of all professionals falls into one of the three categories: Knowledge work, Information work and Physical labor (A, B and C respectively). Professional’s output is judged by these three categories. They earn their wages as a reward through a combination of these three categories of work.

Knowledge work (A) results in identifiable new products (leading to new sources of revenue), new processes required to conceive and realize such new products, as well as applications/use of these products (which in turn leads to additional revenue for the employer). Every company, employer or investor is judged by their ability to develop and deploy new streams of solutions in terms of Product, Process and their application/use.

Information work (B) is what you do, when you are browsing your mail, replying to them, generating reports, making presentations, attending those endless meetings listening to someone. Jobs with high content of information work can be seen in call centers, on-line tech. support workers, those who write codes or implement and administer software support solutions for a variety of applications. While these can be seen in the low wage IT jobs, every professional in every company and at every level spends inordinate amount of time doing “information work”. Much of the front end and back end operations and all of the ERP activities in the factory are all information work. Engineer who spends hours at a time to get the paper work through is spending all that time in information work. Physical labor (C) is the last category of work by everyone. While it is easy to recognize the physical labor in the shop floor, it is prevalent in all jobs and at all levels. Professionals who constantly travel contribute through their physical labor. Long commute to work is another category of physical work by most professionals.

Of these three categories of work, the knowledge work and the solutions as a result of that is most valuable. The information work and the physical labor are merely means to that end. Hence, we can configure an efficiency factor i.e. Professional Efficiency or PE Score.

New Solutions vs. Replication Solutions

PE Score = A / (A + B + C)

In our informal survey of many companies and organizations the PE Score ranges from 15 to 30 percent. Most of the time entrepreneurs and people who work in startup operations work with high PE Score. In most standardized operations or jobs, the professional outcome (A) is small; the job itself is made more efficient through highly efficient means to execute information work (through IT solutions) and decreased labor (Automation) i.e., reducing the denominator in the PE score formula. Those who contribute some combination of small knowledge work, but inordinate effort through information work and labor have a small numerator, with increasingly large denominator. They fall in the middle of the population with decreasingly smaller PE score.

System Thinking

Can you imagine yourself as a professional operating at high PE Score through a series of new solutions? This will require first defining who is a professional and what is a solution?

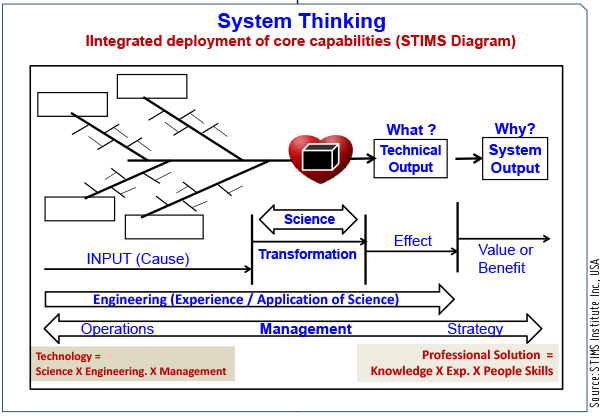

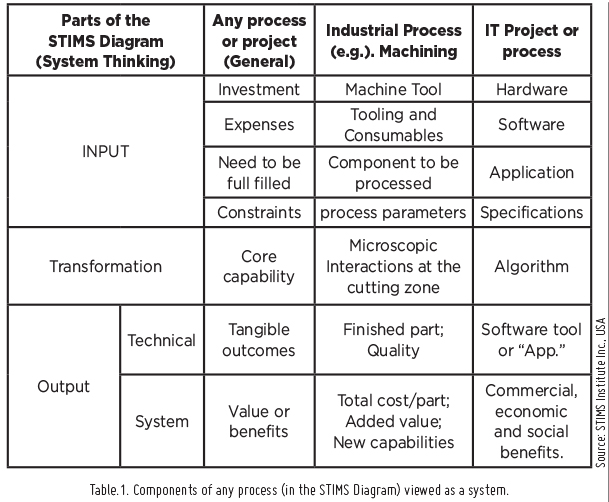

Every professional is a knowledge worker. They develop and implement new solutions. Every solution requires a collection of inputs. When brought together in a logical and orderly manner the inputs change into outputs of use to someone for something. Meeting such needs of someone by transforming the inputs into outputs is what we call as a “solution”.

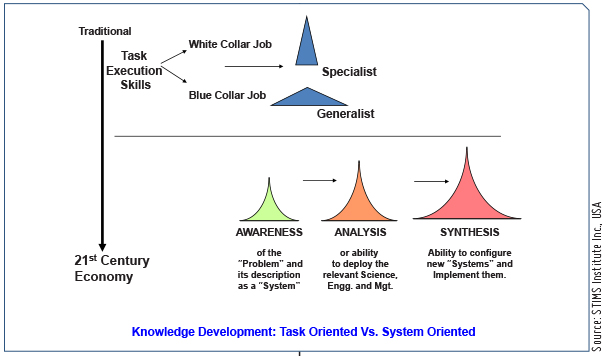

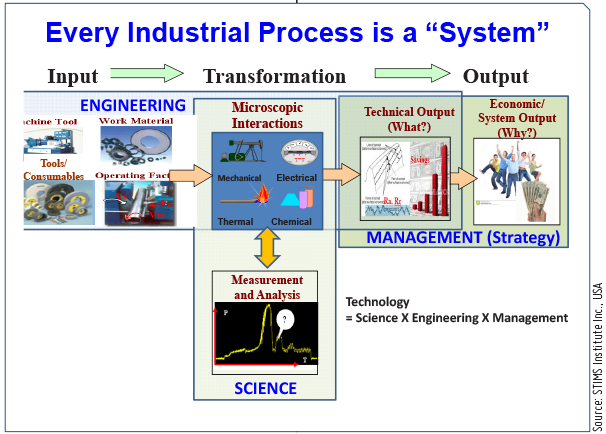

Every solution is an “Input/Transformation/Output system”. Keeping this point of view relentlessly in everything we do is the beginning of system thinking, which brings with it certain unique capabilities:

- Are you looking at the big picture (the solution) or blind folded? Are you able to focus on the picture on the screen as a whole (the solution) or are you fixated on the pixel?

- Do you look before you leap? Do you have a comprehensive view of the problem (or solution) as an input/transformation/outputs system? (See the STIMS Diagram) – Awareness level of system skills.

- Are you driven by data and its analysis or by opinions and “rules of thumb”? Remember, a good carpenter measures twice and cuts once? – This is the Analysis level of system skills.

- When asked “what is 2 + 2?”, do you instinctively answer 4 or say ‘‘Why is this question? Value or benefits? What goes into the 2 and the other 2?’’. Then follow up on the questions until a new solution is developed and implemented? – This is the highest (Synthesis) level of system skills.

Levels of System Thinking skills

STIMS Diagram

With the advent of SPC, TQM and other continuous improvement tools, professionals in every field – especially in the manufacturing world – are taught to solve problems using “Fish bone diagram”. Any fish bone diagram consists of listing all possible causes through the skeleton leading to the effect as the head of the fish.

There are a few problems with this method. First of all, the causes by themselves do not change into effects. For example, the machine tool, work piece, tools and operating methods are all the causes. But they do not automatically result in the effect i.e. good quality part or poor tolerances and finish, etc. There is something – phenomena (machining) – that connects the cause and effect, which we can call as “transformation”. Also effect by itself is not important to us as much as the value or impact of that effect. Hence, to describe a problem completely – as a system – we need a few more additions to the fish bone diagram. This comprehensive description of the problem or solution is the STIMS Diagram.

STIMS Diagram

The listing of inputs clarifies all the stakeholders in the process. They also identify the various sources of knowledge accessible to address the process problems or improve the process to achieve new solutions. These input groups are also the stakeholders interested in the process outcomes i.e. System Outputs. As an example, the successful execution of the industrial process is of interest to the company (investors who bought the machine tool) as well as to the machine tool company that sold the machine. Tooling and Consumables are brought together by the process engineering (and the purchasing) department. But this category of input also represents the range of suppliers whose knowledge is critical for the success of the process. The design and product department has a stake in the “component to be processed” as much as the raw materials suppliers. The process parameters are managed by the maintenance people as well as by the production floor staff.

The technical outputs are the physical or tangible outcomes of any process such as a machined part or welded component, etc. Technical outputs are critically watched by the production staff as well as the QC people. The System Output is ideally the benefit to all stakeholders mentioned above. However, it is generally viewed as the economic benefit to the investors or general management or the accountant. This narrow view of the system output will be questioned by the System Thinker. Instead optimizing the benefits to all stakeholders will also be in the best interest of the process and to gain maximum long-term value out of the solution.

STIMS Diagram, illustrating system thinking for industrial manufacturing processes

Three sources of learning for the 21stcentury economy

While we have described the many stakeholders in the process – both on the input as well as the output side - the process always happens as a result of certain physical phenomena, which we call as the “Transformation”. Quantitative as well as intuitive knowledge of the transformation is the “Science” behind the process. Ability to measure and analyze the in-process signals that occur as a result of the transformation using mobile diagnostic tools brings the science to shop floor manufacturing.

Use of the transformation and fine tuning it through the various inputs to achieve the desired output is the engineering behind the process. Establishing the limits for the technical outputs – e.g. tolerance or part quality – as they reflect on the overall economics – e.g. total cost/part – is the management strategy behind the process.

Thus, every manufacturing process and the technology behind it is the integration of relevant science, engineering and management pertinent to that process. We can teach manufacturing technology as a system. Such education helps manufacturing professionals capable of handling a wide array of problems (with common engineering and management tools) and also dive deep (using the science) as and when required.

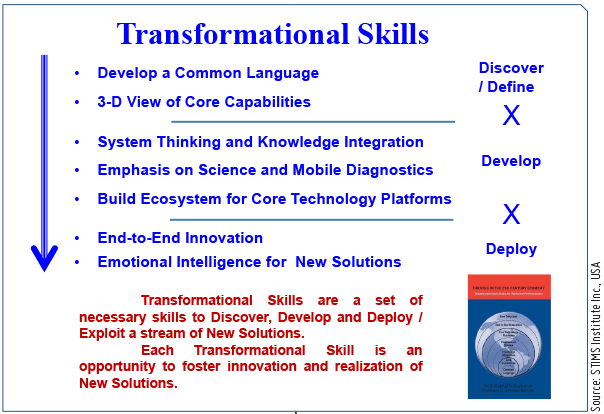

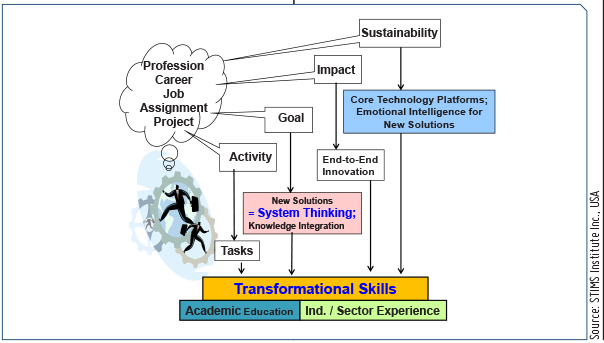

Treatment of the process or solution as a system has many dimensions. We call them as the Transformational Skills. They help to find ways to shift away from task-oriented replication solutions. Instead they help to steer manufacturing professionals towards highly skill intensive new solutions. Together with their academic education and industry experience, the transformational skills form the third leg for lifelong learning strategy for any professional to survive and succeed in the 21st century economy.

Lifelong learning strategy for professional success and career management

Manufacturing professionals have to shift from their current task-oriented jobs and functions where they merely carry out a collection of activities based on “what they are asked to do?” Instead they need to understand the goal upfront. It is easier said than done. How often do you go ahead and start your work before asking your boss or supervisor “Why are we doing this? Who are the stakeholders? How are their benefits addressed comprehensively?” This requires a passion for system thinking. This also promotes our ability to integrate the knowledge from every available resource. Buyers and suppliers are part of the team to add maximum value, not adversaries spiralling downwards the lowest price. With the goal (System output) clarified upfront, these professionals are also committed to the entire innovation chain: Discover, develop and deploy/implement. This end to end innovation is also called as Concept to Commercialization (C2C). Finally, building a team of like-minded professionals with true knowledge and commitment also requires high levels of care and consideration for everyone in the team. This capability to build the necessary eco-system together with emotional intelligence will be the highest evidences of success in the 21st Century manufacturing professionals.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe