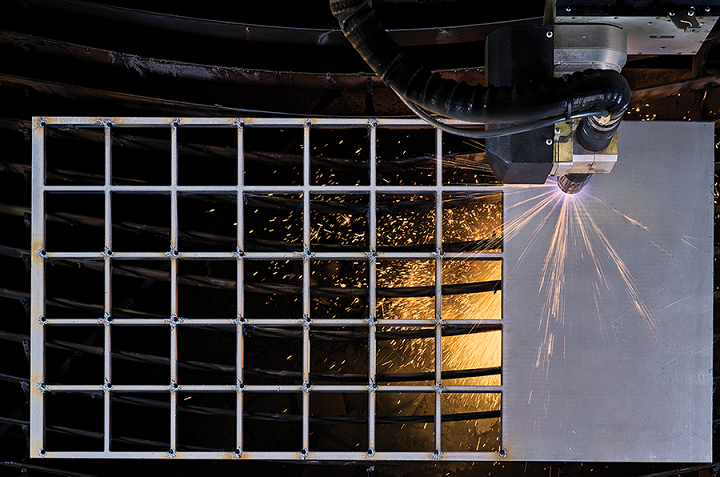

Hypertherm’s New PlateSaver Technology for Maximizing Parts and Profit Per Plate

Roosendaal, The Netherlands – Hypertherm, a manufacturer of industrial cutting systems and software, has recently released PlateSaver™, a new SureCut™ technology that automatically maximizes the number of parts on a plate for more profit per plate.

PlateSaver is available through Hypertherm’s ProNest® and other authorized software for fabricators employing X-Definition plasma to cut mild steel on a CNC table. It combines X-Definition plasma’s arc stability with specialized software parameters to greatly increase material utilization. PlateSaver uses shorter leads when starting and concluding a cut as a result of these parameters, resulting in less wasted space between parts. PlateSaver considers molten metal by employing moving pierces that cause molten splatter to fall within a predictable ‘splash zone’ in addition to shorter lead-ins and lead-outs.

PlateSaver is available through Hypertherm’s ProNest® and other authorized software for fabricators employing X-Definition plasma to cut mild steel on a CNC table. It combines X-Definition plasma’s arc stability with specialized software parameters to greatly increase material utilization. PlateSaver uses shorter leads when starting and concluding a cut as a result of these parameters, resulting in less wasted space between parts. PlateSaver considers molten metal by employing moving pierces that cause molten splatter to fall within a predictable ‘splash zone’ in addition to shorter lead-ins and lead-outs.

SureCut technology improves cutting performance by automatically incorporating thousands of cutting parameters into authorized hardware and software products. True Hole® for bolt-ready holes, True Bevel™ for simplifying the process of cutting beveled edges, and Rapid Part® for significantly reducing cut-to-cut cycle time are all included.

Tom Stillwell, Product Marketing Manager, Hypertherm, explained, “We are excited to introduce this new SureCut technology as it will allow customers to increase their profits through the reduction of waste. By fitting more parts on a plate, customers will spend less time and money purchasing, moving, and storing metal, and also less time tracking and conducting inventory on partially used plate.”

Image Source: Hypertherm, Inc

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe