With a Winning Edge

A look at how CNC machines can prove beneficial to the Indian manufacturing industry and the initiatives taken by Mitsubishi Electric India towards supporting the industry through its innovative offerings of the domain…

Every sector has seen transformations and advancements over the years. The days of numerical controls being solely about servomechanisms are long gone. We are now living in the era of CNC (Computerized Numerical Control) systems. These control systems have aided in a variety of ways, ranging from simple turning to complex machining. The controllers that operate these CNC systems are even more fascinating. Mitsubishi Electric looks ahead to partner with the brands that are focused on global and future-oriented development. CNC stands for Computer Numerical Control, and it refers to the concept of controlling machine tools with a computer. A CNC machine is an electromechanical device that uses computer programming inputs to operate machine shop tools. CNC machining is a widely used process in the manufacturing industry.

An overview of CNC systems

A CNC system is an automated method of controlling machine tools, 3D printers, and other devices through the use of software-programmed microcontrollers. CNC systems have helped achieve the required specifications and output much faster, with little or no manual intervention. The systems are controlled by sequential programs such as G-code or M-code, which are written by coders or generated by Computer-Aided Manufacturing (CAM) systems. The codes may be sliced or modified depending on their area of application. The machine unit is connected to the microcontroller unit or controller, which stores the coded programs. With the constant advancement in technology, CNC systems have found use in a variety of industries, including Electronics and Healthcare.

When it comes to the Manufacturing sector in India, CNC machines have had a significant positive impact. They are known to provide a slew of advantages, including increased productivity, higher-quality products, shorter development times, and higher profits. Without CNC machines, one would have to hire more workers, face difficulties replicating a specific product, and deal with a host of other challenges. These machines are employed widely in the aerospace, electronics, defense, manufacturing, industrial, and medical domains.

Advantages of CNC machines

CNC machines offer a number of advantages, including:

Making mass production easier

CNC machining makes more sense than conventional machining when there is a high demand for a product, and one needs to manufacture the same piece over and over.

Workforce optimizationand safety

When using traditional machinery, one needs to hire experts and other staff to deal with the machine. Then there are the ongoing costs of maintenance and repairs, which must be considered. Because of all of these factors, traditional machinery can be quite costly. However, this is not the case with CNC machines. As fewer people are required to operate these machines, the labor cost gets reduced.

Increasing the number of production options

The production processes get boosted by the easy-to-use CNC machines. The CNC software assists in creating products that are nearly impossible to make manually or with traditional machinery.

Being a digital era’s machinery

Everyone nowadays wants to adapt to the trends of the digital era and become tech-savvy. CNC machines allow you to do just that. By virtue of their operation, CNC machines use computers to control machine tools, resulting in reduced development time, increased cost savings, and higher profits.  Assisting in the production of high-quality products

Assisting in the production of high-quality products

Several customers currently face issues with the quality of their products. This is a challenge that can easily be solved if CNC machines are introduced into the Indian Manufacturing industry. CNC machines allow making the same precise cut every time while maintaining consistent quality.

Mitsubishi Electric, a global leader in the sales and manufacturing of electrical and electronic products and systems, offers Computerized Numerical Controllers (CNCs) that are smoother, faster, and easier to use and offer higher accuracy. The M800/M80 Series, E80 Series, C80 Series, and other CNC control systems are offered by the company.

These CNC features help in the production of high-quality products with the utmost efficiency and standardized quality.

Increasing productivity

CNC tremendously increases productivity for machine tools as the machinery can be automatically run without requiring continuous attention from its operator. The wide range of CNCs offered by Mitsubishi Electric India enables businesses to achieve smoother and faster operations and a higher level of product finish. At the same time, it allows for increased productivity and profitability in operations. Due to the outstanding features, the CNC products offered by Mitsubishi Electric are proving to be extremely useful for the Indian Manufacturing industry. Aside from the advantages mentioned above, they are also energy-efficient, have a lower environmental impact, and ensure less wastage.

Everyone nowadays wants to adapt to the trends of the digital era and become tech-savvy. CNC machines allow you to do just that. By virtue of their operation, CNC machines use computers to control machine tools, resulting in reduced development time, increased cost savings, and higher profits.

Initiatives by Mitsubishi Electric to support the industryInitiatives by Mitsubishi Electric to support the industry

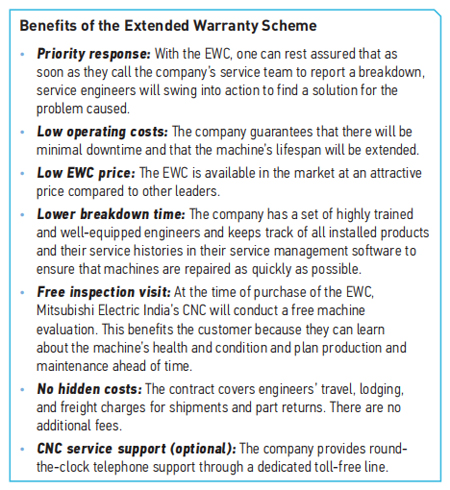

Extended warranty: Mitsubishi Electric India has always prioritized product and service improvement, focusing on delivering high-performance and cost-effective solutions. In a similar vein, the company has introduced a new Extended Warranty Contract (EWC) for specific Computerized Numerical Controllers to help the customers with better services. This ensures prompt responses, reliable technologies, and a user-friendly support system for clients all over India, resulting in better after-sales services.The extended warranty contract covers the following CNCs from Mitsubishi Electric India:

• ECONOMICAL: E70/E80 series with turning/grinding/gantry machines for cost-effective controllers.

• STANDARD: M60/M70/E70/M80/E80 series for standard controllers.

• CUSTOM: Windows/customized controllers, including the C70/C80 series, for Japanese and Taiwanese machine tool builders.

Preventive Maintenance (PM): It’s critical to have a proper preventive maintenance plan in place to keep shop machines running smoothly. Routine inspections help the customers improve output efficiencies, increase uptime, and improve profit margins.

CNC SS24 Round the Clock Support: Mitsubishi Electric has a dedicated toll-free line available 24 hours a day and seven days a week. At the toll-free number and via email, the company’s CNC front engineers are available 24x7 to provide technical support to ensure hassle-free operations for the registered customers.

Working to make India self-sufficient: Mitsubishi Electric India’s CNCs aspire to be a trusted partner for businesses seeking global and long-term growth. The company is also assisting India’s Manufacturing industry with solutions that target specific growth segments. This step is being taken to support the Government’s ‘Make in India’ initiative among manufacturers across the country and ensure that Atmanirbhar Bharat comes into practice with high-quality and reliable solutions.

Mitsubishi Electric, a global leader in the sales and manufacturing of electrical and electronic products and systems, offers CNCs that are smoother, faster, and easier to use and offer higher accuracy.

MASAYA TAKEDA

General Manager

CNC Systems

Factory Automation & Industrial Division

Mitsubishi Electric India Pvt Ltd

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe