Creating Layer by Layer

Additive manufacturing, a technology that started with the goal of rapid prototyping, has now expanded its goal towards making lighter, complex shapes with acceptable strength. The reduction in the material used, lesser number of parts for maintenance, lesser transportation, and reduced energy consumption make this manufacturing technique a truly sustainable solution.

A recent conversation with one of my non-Indian friends on the topic of how we are taking on sustainable development ended with my reply: “When any automobile company wants to sell its product in India, the first question they come up with is ‘Kitna deti hai/What is the mileage?’” This translates to how efficient/less polluting a vehicle is.

Jokes apart, the recent pandemic has made people and organizations rethink sustainable development. Millions of hectares of forest are lost yearly, and billions of kilograms of toxic material waste are generated every year and pollute both water and air. Many big cities in the world today are in the red zone. Hence, there is an urgent need to minimize our carbon footprint at every stage.

When introducing a new production technology, because many parts must be produced and verified until target quality can be achieved, the traditional trial-and-error validation process is extremely time-consuming and expensive.

Advantages of additive manufacturing

Creating a simulation-based workflow can predict part quality and has the potential to significantly reduce the process time required by the traditional method. Simulation software lets one create additive manufacturing (AM) designs and simulate the metal additive manufacturing process to reduce product development time. It is an end-to-end manufacturing solution that can save both time and money.

Let me elaborate on the new evolving technology in the manufacturing process and detail the benefits and challenges that lie ahead of this advancement in manufacturing technology.

Additive manufacturing makes the product lighter

In a conventional product design process, engineers use techniques like generative design, topology optimization, and so on to improve their product strength while keeping the weight in check. In general design processes, design starts with a somewhat known configuration initially and then parametric studies on dimensions are performed along with a few constraints. Many of these constraints came from the manufacturability perspective as well. This approach, to help achieve improvement on the designed parts, was not optimal. Hence, products created by the conventional process have much scope for improvement, like making them lighter and, thereby, reducing the overall carbon footprint. Parts designed and printed with a complex lattice structure are becoming very common with additive technology. This results in lighter products without compromising their functionality requirements for strength.

As the name suggests, this technique is all about adding materials layer by layer to create parts, whereas traditional manufacturing worked on the subtraction of material from an initial block. Hence, this drastically reduces the waste or scrap generation that results in saving energy through the recycling process.

Additive manufacturing reduces wastage

The gap created by conventional manufacturing constraints is getting filled with the new additive manufacturing technique, also known as 3D printing. It is capturing the imagination of the international business world and innovators because of the enormous possibility of shape and complexity. As the name suggests, this technique is all about adding materials layer by layer to create parts, whereas traditional manufacturing worked on the subtraction of material from an initial block. Hence, this drastically reduces waste or scrap generation that results in saving energy through a recycling process. One can argue that the support structure required for 3D printing is a waste. However, it is comparatively very less.

Additive manufacturing enables companies to realize digitalization

Companies have great potential to realize their digitalization journey with additive manufacturing. Even if you keep printing parts aside, the journey towards digitalization requires a digital form of information to store, share, inspect, and reuse. AM provides a platform for various stakeholders, starting with the designer, manufacturer, supplier, and operator. They all share the same common source of truth. This data can be easily stored on the cloud and made available among all stakeholders. This leads to the realization of a critical stage called the ‘Digital Thread’ part of digital manufacturing. Digital manufacturing emphasizes the use of technology in a ‘Digital Thread’ environment to efficiently manage change, inspect, and save energy and cost. The transformation of physical files to a digital ones makes this technique an environmentally friendly one as well.

Additive manufacturing simplifies the manufacturing assembly lines

AM supports product innovation and market responsiveness because designs can go from a digital file to a finished product in a very short span of time. It is not only the complexity, but also the combining of many different parts of a large assembly into a single bulk part that results in a reduced number of parts required for that asset. These benefits are taken to a new height by various industries. For example, aerospace companies are trying to build a rocket engine with 100 parts instead of 10,000 parts. This was just a dream a few decades ago, but today it’s realizable using the additive technique. This way, design has the potential to optimize further because there are no more end-part constraints. Hence, it simplifies the manufacturing process and assembly lines that translates to fewer man-hours spent on the assembly line and better handling of logistics. This makes the entire assembly lighter and the final product is more efficient.

Additive manufacturing consumes less energy

The initial part of material generation like mining and processing could have the same energy requirement for any type of manufacturing process. But it has been observed that traditional CNC machining consumes more energy than additive for similar part creation. This difference becomes more significant, especially for energy-intensive material products like titanium. AM also allows organizations to produce parts very close to their users. Reduced transportation costs for moving various raw materials and parts from one location to another will reduce costs by a greater proportion, in addition to lowering environmental entropy.

Challenges in additive manufacturing In recent years, additive technology has drawn the attention of many researchers and innovators, and has built a big expectation of transforming the Manufacturing industry to be more economical and eco-friendly. However, the journey of adopting this technology by the industry is not a smooth one as any other new innovative technology.

The range of materials that qualifies and satisfies all the regulatory requirements for industrial parts is still evolving. Most printers are limited by their printing volume capacity. Industries have many large-sized components and, at present, very few printers are available to meet such requirements. There is a large scope of improvement in the energy required for printing between different additive techniques.

Since AM is more digital, it is also prone to major cyber-attacks. Hackers may be able to hack the digital file over the Internet, look at the information and play unethical games. With new business models evolving, many companies may just share the printed CAD models where users can use this service to print the product on their own. Although 3D printing may not be used for the entire product design, industries are taking advantage of both methods and technologies.

The future

With the progress in Artificial Intelligence (AI) and Machine Learning (ML), this new technology is going to bring immense benefits to Manufacturing industries. With the use of various ML techniques, engineers can now characterize the material in different classes and groups. Process parameters can be further optimized by the processing of large sets of data. Product defects can be analyzed better and faster. Engineers can do a trade study between process parameters and product functional outputs. They can even generate a surrogated model to optimize product quality and process with minimum sets of data.

Since additive manufacturing is more digital, it is also prone to major cyber-attacks. Hackers may be able to hack the digital file over the Internet, look at the information and play unethical games.

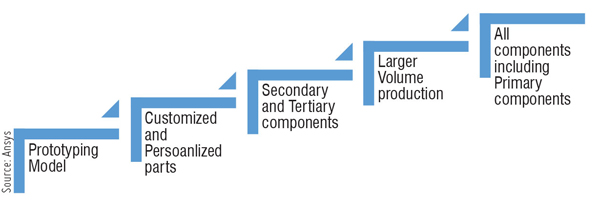

There are numerous analytical as well as physics-based tools and techniques that are available to address many of the challenges faced by adopters of additive technologies. Engineers and scientists are leveraging this tool to predict distortion compensation, support generation, thermal strain, layer by layer visualization, potential blade crash, and so on to print the part effectively and efficiently as per requirements. Physics-based tools are also used by engineers to validate those parts for different environmental conditions and reduce the expensive process of trial and error. A technology that started with the goal of rapid prototyping has expanded its goal towards making lighter, complex shapes with acceptable strength. The road ahead for the adoption of this technology could be bumpy, but it’s encouraging to be a witness to various resource reductions.

LALAN SINGH

Technical Manager A&D

South and ASEAN

Ansys

lalan.singh@ansys.com

Source: Ansys

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe