ADVOCATING INTELLIGENT AUTOMATION

Chennai-based next-gen startup Jidoka Technologies is in the field of automated cognitive inspection, delivering AI-powered defect detection systems for mitigating pain points experienced by the manufacturing industry. Read on to know about the founders’ path-breaking automated QC solutions and their plans for a smart tomorrow…

Coming from a Manufacturing background, Sekar Udayamurthy, Dr Krishna Iyengar and Vinodh Venkatesan recognized a huge opportunity for automated QC solutions that would help to increase the efficiency of the manufacturing processes across industry verticals.

The trio identified several pain points faced by manufacturers on the shop floor with manually driven QC processes. This is mostly in the area of visual quality checks done on the products manufactured – either in-process or as final inspection before they are shipped to the customer. Due to human subjectivity, decision-making varies based on the experience and expertise in addition to fatigue setting in. The accuracy rate of human inspection to detect defects is generally not more than 90 percent. Moreover, in high-volume production lines where visual inspection is not deployed 24x7, there remain backlogs that create bottlenecks.

Being equipped with expertise and the know-how in manufacturing and digital technologies, they then identified a gap in the market to be filled. Hence, in 2018 they came up with Jidoka Technologies, a venture to serve the fast-expanding manufacturing market with their AI-Powered Defect Detection Systems to consistently enable 100 percent visual inspection.

“Due to the pandemic, where manpower for manufacturing has become scare, leveraging our QC solutions is ensuring business continuity to manufacturers. Also, with increase in exports of manufacturing goods, we foresee a huge demand for our solutions from the industry,” reveals Sekar Udayamurthy, Co-founder & CEO, Jidoka Technologies. This is the reason the startup, with a current turnover of `33 lakh has a target for the ongoing fiscal year as `4 crore for the Indian market and `3 crore as exports. Its clients include Nexteer Automotive, Indo Schottle, MIM – to name a few.

Jidoka stands for a principle that advocates ‘intelligent automation’ or ‘automation with a human

touch’ in Japanese. Currently operating in India, the startup serves Automobile, Pharma,

General Manufacturing, Electronics and Printing industries.

Automation with a human touch

Jidoka QC solutions help to automate the process of visual quality, increasing consistency and accuracy at high speed by leveraging AI (Artificial Intelligence) / ML (Machine Learning), Deep Learning and Analytics. Jidoka stands for a principle that advocates ‘intelligent automation’ or ‘automation with a human touch’ in Japanese. Currently operating in India, the startup serves industry verticals including Automobile, Pharma, General Manufacturing, Electronics and Printing.

Jidoka QC solutions help to automate the process of visual quality, increasing consistency and accuracy at high speed by leveraging AI (Artificial Intelligence) / ML (Machine Learning), Deep Learning and Analytics. Jidoka stands for a principle that advocates ‘intelligent automation’ or ‘automation with a human touch’ in Japanese. Currently operating in India, the startup serves industry verticals including Automobile, Pharma, General Manufacturing, Electronics and Printing.

“We leverage Deep Learning, a subset of Machine Learning in AI, which teaches machines to learn by example. This technology can recognize features that distinguish trends and make intelligent predictions and decisions. It scales the intelligence of human visual inspection with the reliability, consistency and speed of a computerized system,” explains Udayamurthy.

“We use a combination of Supervised and Unsupervised Computer Vision AI algorithms. In the low data regime, we use our patented Anomaly detection algorithm along with clustering,” he adds.

Image Data augmentation aids Supervised AI algorithms like Image Classification, Object Detection and with regression algorithms, model testing, monitoring and MLOps are done.

“We deliver customized dashboards for the Management, Quality Assurance, Supervisors and Operators so that the right information is presented to the right people at the right time. Users can analyze data on various products, types of defects, severity, occurrence and generate reports,” he informs further.

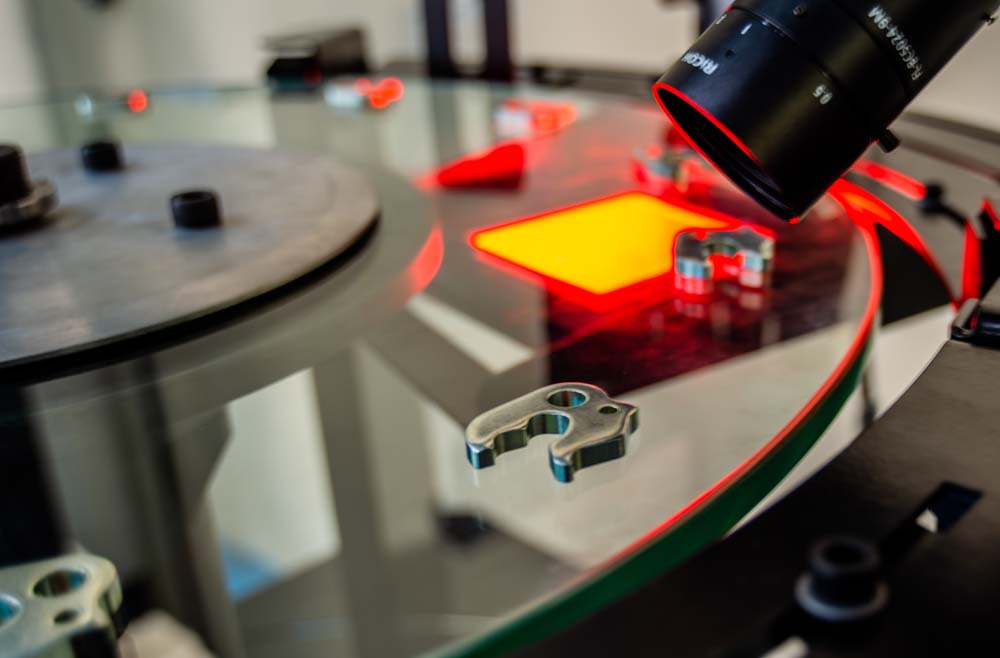

How Jidoka solutions matter Jidoka’s state-of-the-art automated cognitive QC solutions combine the power of AI with automation and computer vision in defect detection, delivering 98 percent or higher accuracy in the QC process, claims Udayamurthy.

The QC solution has both hardware and software components. The hardware platform has three trademarked structural shells that the company uses to customize the right solution for different products: Huron for large-volume complex products; Tigris for flat and lightweight products; and Miyake for manual load and unload with selective checking.

“We also integrate our software with a third-party radiography equipment to identify defects in X-ray images, Bubble Test (wet leak) systems to identify cracks in castings. Other hardware designs can be specially built depending on the component requirement. Solutions that integrate with robot is also in progress,” he reveals.

The software platform Kompass marries real-time decision-making to the state-of-the-art AI to create an end-to-end system for visual defect system. The software provides a turnkey solution that fits seamlessly into the production line of different manufacturers. The system uses a digital twin created by the hardware and maps it to the AI to deliver up to 1200 decisions per minute.

“We are an E2E solution provider with proven implementation experience and not merely a software platform,” he states.

When asked how different are the company’s solutions from others available in the market and their tangible benefits, Udayamurthy states that their customers will be able to recover their RoI on what they have invested in the Jidoka system in as less as 12-15 months.

He enlists the tangible benefits along with the estimation of cost savings per year:

- Regarding quality inspection, human biases will be eliminated, leading to 30 to 40 percent reduction in false rejections. With 5 to 8 percent improvement in detection, there will be a higher level of customer satisfaction adding at least 1 percent to new revenues.

- In the QA process, Corrective and Prevention Actions (CAPA) can be implemented to eliminate non-conformities with effective analysis. With manual inspection or with conventional machine vision installations, the analytics is not available for the user to take action on the defects.

- A 20 percent increase in the speed of inspection can be achieved in the Product Control aspect with inspection as a bottleneck getting eliminated and increase in throughput by 33 percent.

- We provide an E2E solution that delivers committed output backed by a commercial model.”

Smart minds behind the venture

Smart minds behind the venture

Along with Udayamurthy, the other two Co-founders Dr Krishna Iyengar and Vinodh Venkatesan are company CTO and COO, respectively.

With more than 25 years of experience in building Product and Digital platforms in North America and passion for technology, Udayamurthy oversees the platform architecture and performance, besides building effective and high-performing teams.

Dr Iyengar is a technical innovator and leads the product development and data science divisions.

With a rich experience in manufacturing and previous startup experience, Venkatesan heads the marketing, sales and operations functions at Jidoka Technologies.

Teething issues and future plans

Talking about initial pain points, Udayamurthy shares, “On the technical side, we had to streamline our MLOPs to ease the delivery of models. Scaling of cameras and working with the vendors to iron out technical issues were part of the process. We also had to streamline our implementation process to ensure adequate check and balance to deliver the committed outputs.”

Talking about initial pain points, Udayamurthy shares, “On the technical side, we had to streamline our MLOPs to ease the delivery of models. Scaling of cameras and working with the vendors to iron out technical issues were part of the process. We also had to streamline our implementation process to ensure adequate check and balance to deliver the committed outputs.”

“Getting the right talent was another challenge so we hired the talent that was versatile. We provided them in-house training to make them productive in a very short span of time,” he adds further.

The team is looking at furthering the company’s product development in two areas:

The first step, shares Udayamurthy, is to move to a KPI-driven triaging of quality for organizations i.e., managing economic, quality and production constraints and bringing in an incremental change in quality.

“Secondly, we are looking at the need of customers to have data to ensure higher levels of accuracy, which is done by various features for data augmentation and experience-driven inferencing. For this, we will leverage the cutting-edge work done in AI/Machine vision such as Anomaly detection, 3D image generation, etc., and to this effect we are productionizing some of the concepts while patenting them as well. We continue to evolve in the hardware platforms as well,” he states.

By 2025, Jidoka Technologies aims to expand its services across the global market of the US,

the UK, Europe, Southeast Asia besides serving in the Indian sub-continent.

By 2025, the company aims to expand its services across the global market of the US, the UK, Europe, Southeast Asia besides serving in the Indian sub-continent.

Poonam Pednekar

Chief Copy Editor

Magic Wand Media Inc

poonam.pednekar@magicwandmedia.in

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe